Method for performing regenerating treatment on alkylated waste sulfuric acid

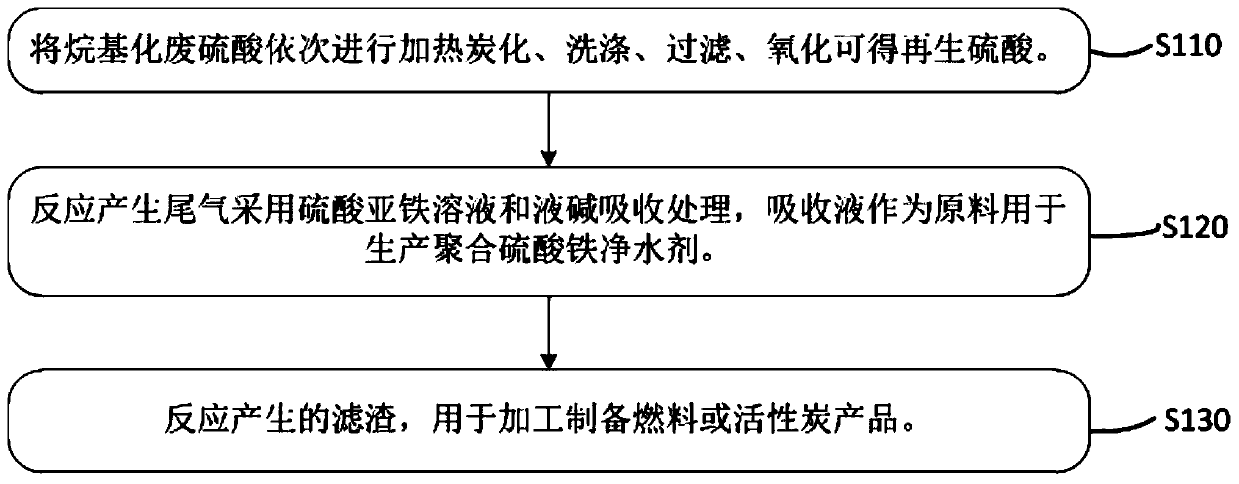

A technology for alkylating waste sulfuric acid and treatment methods, which is applied in the direction of sulfur trioxide/sulfuric acid, chemical instruments and methods, ferric sulfate, etc., can solve the problems of high equipment maintenance cost, difficult to handle, and waste residue that cannot be handled, and achieve good results Environmental benefits and economic benefits, the realization of resource recycling, the effect of low sulfuric acid reduction decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 100 g of alkylated waste sulfuric acid into a three-necked flask with a capacity of 500 ml, heat up to a temperature of 150° C. for 30 min, stop heating and lower the temperature. Add 100g of clear water to the reactor for stirring and washing, the stirring speed is 100r / min, and the stirring time is 30min, filter off the solution, and repeatedly wash with clear water to neutral filtrate. Carry out oxidation treatment to brown waste sulfuric acid filtrate, adopt mass fraction to be 30% hydrogen peroxide as oxidant, its addition is 3% of waste sulfuric acid mass, be 80 ℃ at reaction temperature, reaction time is under the condition of 30min, make waste sulfuric acid filtrate It is treated as colorless and transparent regenerated sulfuric acid. The tail gas produced by the reaction is absorbed by the first-level absorption liquid as a ferrous sulfate solution with a ferrous iron content of 7% and the second-level absorption liquid with a mass fraction of 15% sodium hy...

Embodiment 2

[0037] Add 100 g of alkylated waste sulfuric acid into a three-necked flask with a capacity of 500 ml, heat up to a temperature of 200° C. for 5 min, stop heating and lower the temperature. Add 100g of clear water to the reactor for stirring and washing, the stirring speed is 300r / min, and the stirring time is 30min, filter off the solution, and repeatedly wash with clear water to neutral filtrate. The brown waste sulfuric acid filtrate is oxidized, and the mass fraction is 30% hydrogen peroxide as the oxidant, and its addition is 1% of the waste sulfuric acid mass. At a reaction temperature of 100°C and a reaction time of 60 minutes, the waste sulfuric acid filtrate is It is treated as colorless and transparent regenerated sulfuric acid. The tail gas produced by the reaction is absorbed by the first-level absorption liquid as a ferrous sulfate solution with a ferrous iron content of 9% and the second-level absorption liquid with a mass fraction of 20% sodium hydroxide solutio...

Embodiment 3

[0039] Add 100 g of alkylated waste sulfuric acid into a three-necked flask with a capacity of 500 ml, heat up to a temperature of 175° C. for 15 minutes, stop heating and lower the temperature. Add 100g of clear water to the reactor for stirring and washing, the stirring speed is 200r / min, and the stirring time is 30min, filter the solution, and repeatedly use clear water to neutralize the filtrate. Carry out oxidation treatment to brown waste sulfuric acid filtrate, adopt the hydrogen peroxide of mass fraction 30% as oxidant, its addition is 2% of waste sulfuric acid mass, be 90 ℃ at reaction temperature, reaction time is under the condition of 50min, make waste sulfuric acid filtrate It is treated as colorless and transparent regenerated sulfuric acid. The tail gas produced by the reaction is absorbed by the first-level absorption liquid as ferrous sulfate solution with a ferrous iron content of 8% and the second-level absorption liquid with a mass fraction of 18% sodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com