A kind of preparation method of alkyl substituted tetrahydrodicyclopentadiene dimer and its application as jet fuel

A dicyclopentadiene dimer and alkyl technology, which is applied in the direction of liquid carbon-containing fuel, carbon-based compound preparation, hydroxyl compound preparation, etc., can solve the problems of freezing point pollution, limited source of raw materials, single product components, etc. Achieve the effect of slowing down the consumption of fossil fuels, reducing the cost of preparation, and the process consumes a lot of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

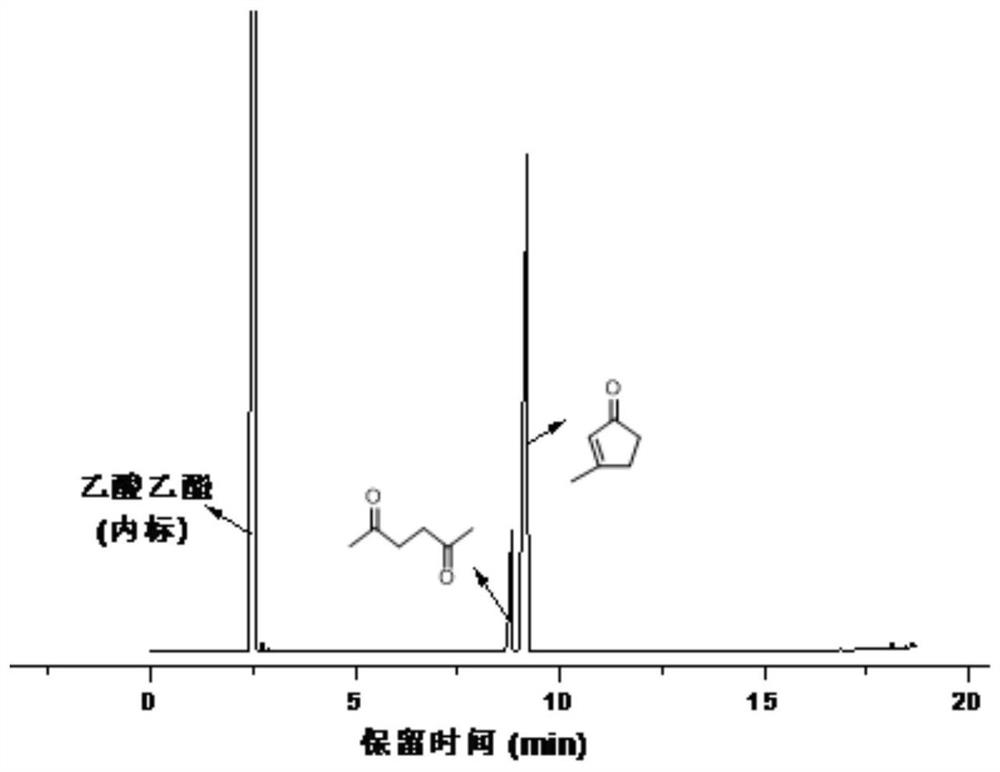

[0049] Add 3g of 2,5-hexanedione and 10mL of water into a 25mL three-necked flask. Under an inert atmosphere (nitrogen is selected), add 400mg of CaO after heating up to 150°C. After reacting for 14h, analyze the product by gas chromatography. The yield of methylcyclopentenone reaches 98%. Its GC-MS diagram is as follows figure 1 shown.

Embodiment 2-20

[0051] Same as Example 1, under a nitrogen atmosphere, use acid-base bifunctional catalysts magnesium aluminum hydrotalcite, magnesium zirconium hydrotalcite, calcium zirconium hydrotalcite (the ratio of the two cations of the hydrotalcite used is between 1 to 10); or an alkaline catalyst Magnesium oxide, calcium oxide, zirconium hydroxide, sodium hydroxide, potassium hydroxide, magnesium hydroxide; or acid catalyst phosphotungstic acid (HPW), HZSM-5, Hβ, HY, H 2 SO 4 , HCl, sulfonic acid resin (such as Amberlyst-15), fluorosulfonic acid tree (such as Nafion-212) (the SiO of the molecular sieve used 2 / Al 2 o 3 The ratio is in the range of 10 to 200) as a catalyst to catalyze the reaction of 2,5-chain diketones to prepare alkyl-substituted cyclopentenones. The results of reactant and its consumption, catalyst and its consumption, solvent type and its consumption, reactant conversion, reaction temperature, reaction time and alkyl substituted cyclopentenone yield are listed i...

Embodiment 21

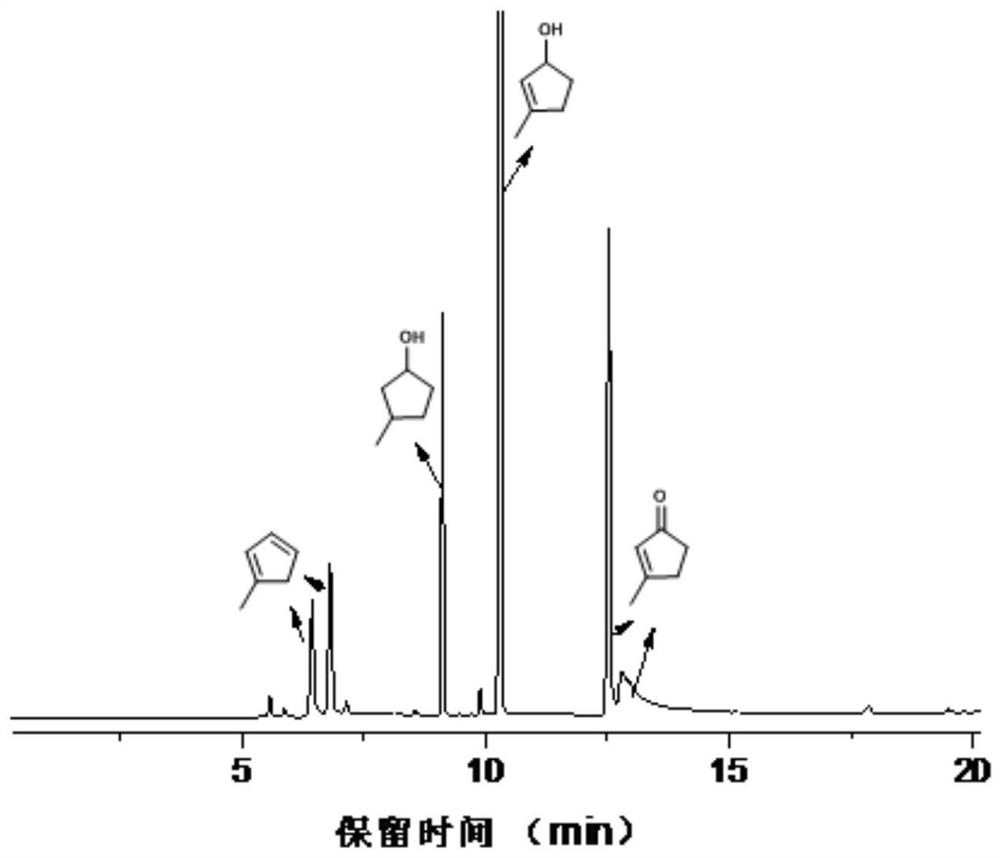

[0056] 154mg of methylcyclopentenone, 3.2mL of methanol and 149mg of CeCl 3 .7H 2 O (co-catalyst) joins in the round bottom flask of 25mL, adds 31mg sodium borohydride at 0 ℃, after reaction 20min, the transformation rate of methylcyclopentenone 100%, methylcyclopentenol yield is higher than 98%. Its GC-MS diagram is as follows figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com