Nanocellulose powder material and preparation method, redispersed nanocellulose slurry containing the same, and application

A nanocellulose and powder material technology, applied in the field of nanocellulose powder material and preparation, and redispersed nanocellulose slurry, can solve the problems of coating instability, high price, low nanocellulose content, etc. Improve scrub resistance, reduce costs, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

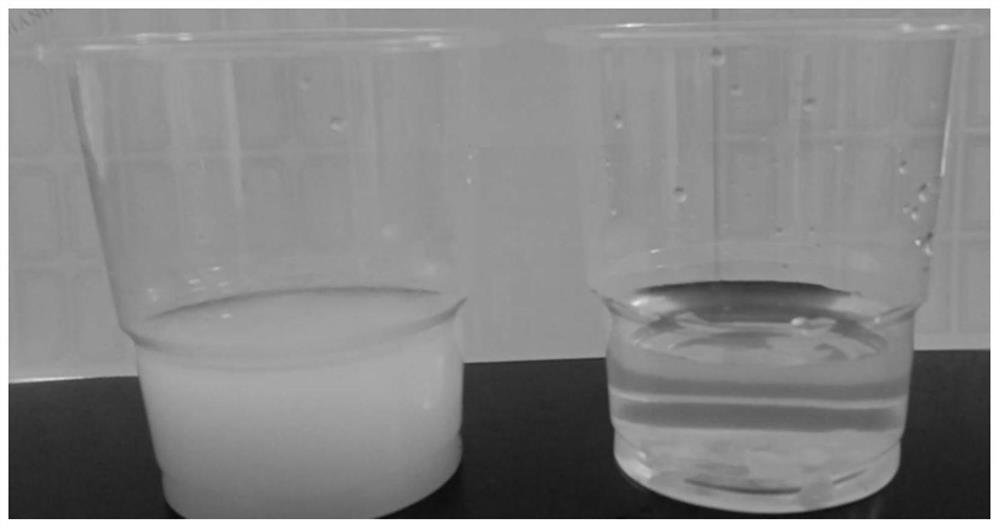

[0056] A nanocellulose powder material is composed of 85wt% nanocellulose, 12wt% water-soluble polymer and 3wt% plasticizer.

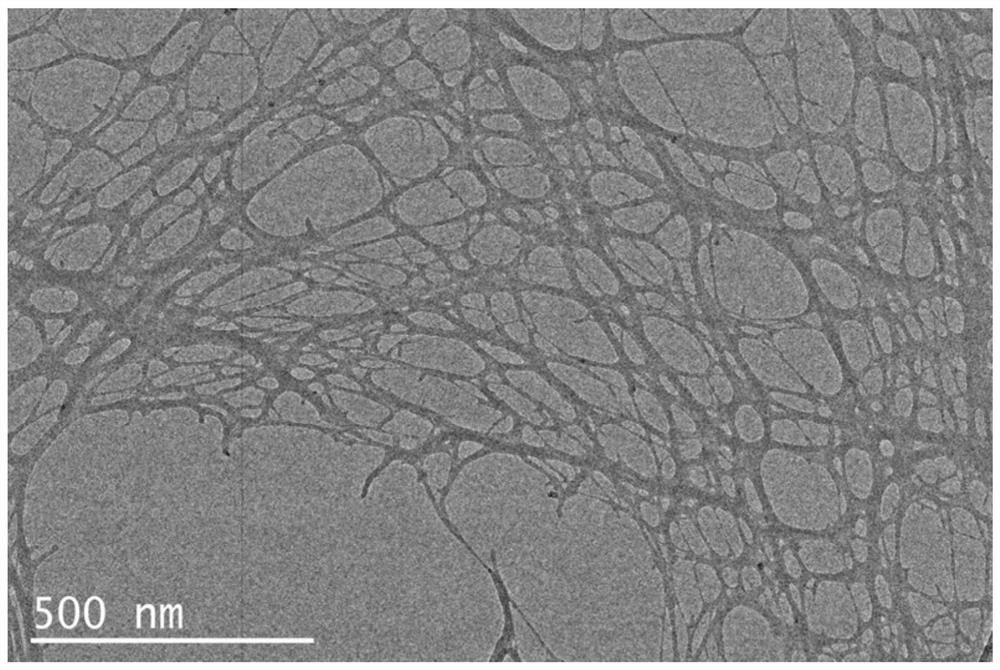

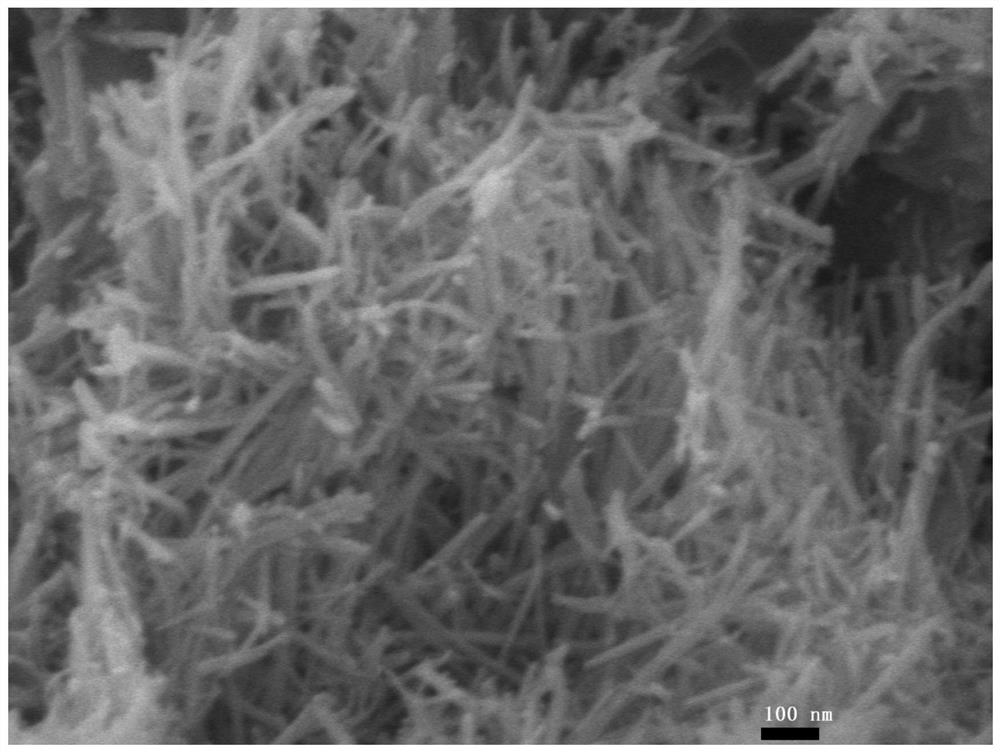

[0057] Among them, the diameter of nanocellulose is 8-20nm, and the aspect ratio is 100-200; the water-soluble polymer is polyvinyl alcohol PVA088-05, the degree of alcoholysis is 88, and the viscosity is 5mPa·s; the plasticizer is glycerol .

[0058] The preparation method is as follows:

[0059] (1) Preparation of water-soluble polymer solution

[0060] Water-based polymer, plasticizer and distilled water are mixed to prepare an aqueous polymer solution with a concentration of 20%;

[0061] (2) Preparation of powder materials

[0062] Mix the nanocellulose slurry with a solid content of 4% and the aqueous polymer solution, and dilute it to a total solid content of 3.5% with distilled water; at room temperature, use a high-speed stirrer (400 rpm) to carry out Stir and disperse at high speed for 40 minutes; then oven-dry and pulverize at 95° C. to ...

preparation example 2-4

[0064] The difference with Preparation Example 1 is that the degree of alcoholysis of the polyvinyl alcohol of this Preparation Example is 100, and the viscosity is 40mPa·s (Preparation Example 2), the degree of alcoholysis is 100, and the viscosity is 50mPa·s (Preparation Example 3), The degree of alcoholysis was 85, and the viscosity was 3 mPa·s (Preparation Example 4).

preparation example 5-6

[0066] The difference from Preparation Example 1 is that in this Preparation Example, polyvinyl alcohol was replaced by polyethylene glycol (molecular weight 20,000, Preparation Example 5) and polyvinylpyrrolidone K90 (Preparation Example 6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com