Method for preparing porous activated charcoal by using biological bases and product of method

A porous activated carbon and bio-based technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problem of poor rate performance and cycle stability of carbon materials, poor pore structure of carbon materials, increased electrolyte transmission resistance, etc. problem, to achieve the effect of simple and controllable preparation process, low cost, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Utilize sodium alginate to prepare the method for porous activated carbon, the steps are as follows:

[0039] (1) Dissolve 2g sodium alginate in 200mL, 10%wt KHCO with continuous stirring for 1h 3 In the aqueous solution, stir slowly for 2h and add 1wt% BaCl 2 Solution 100mL, form a non-water-soluble gel, filter with suction, wash with water, wash with ethanol, and dry;

[0040] (2) Under nitrogen atmosphere at 2°C·min -1 The heating rate was increased to 700°C, and then kept for 1h.

[0041] (3) wash the sample of step (2) with dilute hydrochloric acid (8%), hot water and ethanol, and dry to prepare porous activated carbon, which is designated as PAC2.

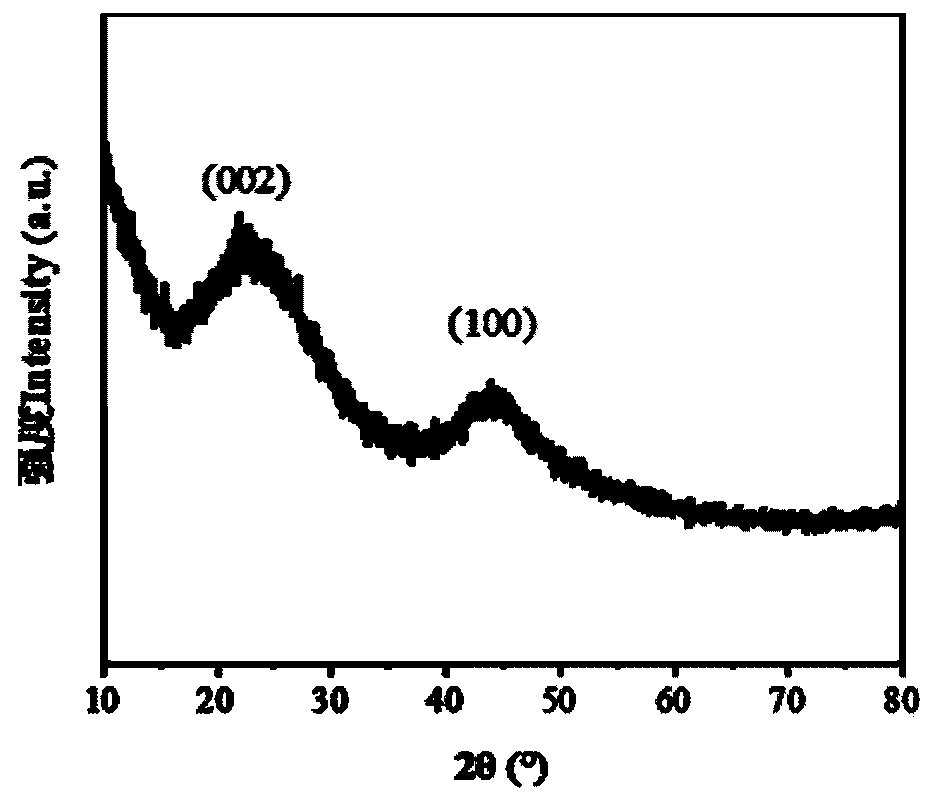

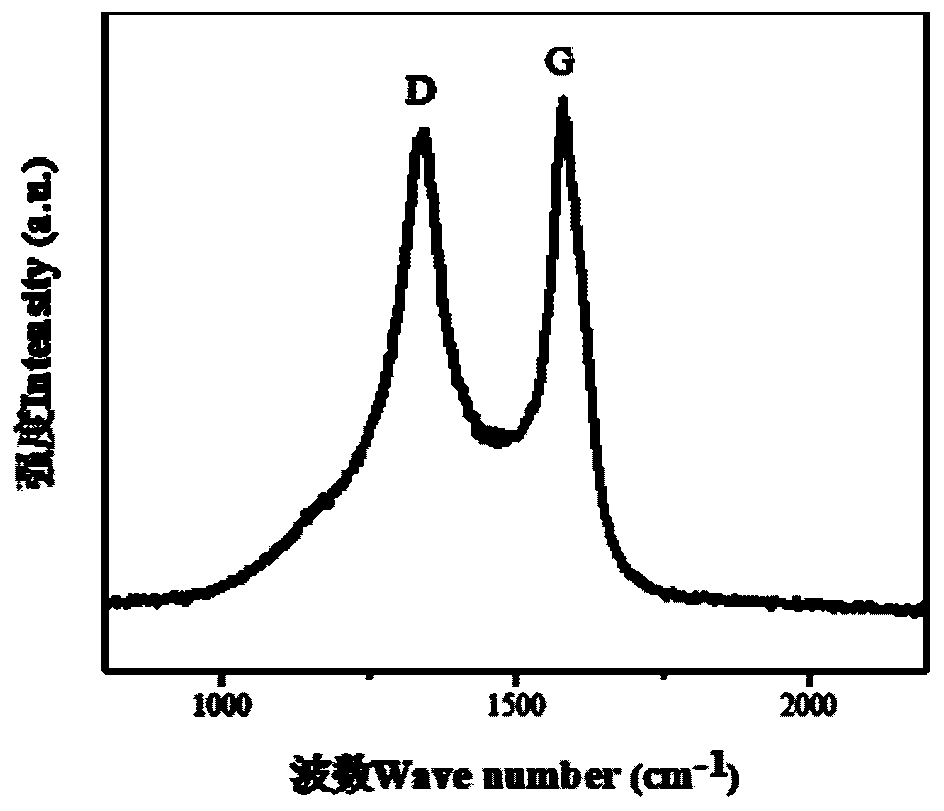

[0042] figure 1 For the X-ray powder diffraction pattern of the honeycomb porous activated carbon PAC2 prepared in embodiment 1, from figure 1 It can be seen that the prepared carbon material shows (002) and (100) characteristic diffraction peaks of carbon, and the surface has a certain degree of graphitization.

...

Embodiment 2

[0045] Utilize sodium alginate to prepare the method for porous activated carbon, the steps are as follows:

[0046] (1) Dissolve 2g sodium alginate in 100mL, 20%wt KHCO with continuous stirring for 1h 3 After being in the aqueous solution, stir slowly for 2h and add 1wt% BaCl 2 Solution 100mL, form a non-water-soluble gel, filter with suction, wash with water, wash with ethanol, and dry;

[0047] (2) Under nitrogen atmosphere at 6°C·min -1 The heating rate was increased to 900°C, and then kept for 2h.

[0048] (3) Wash the sample in step (2) with dilute hydrochloric acid (8%), hot water, and ethanol, and dry to prepare porous activated carbon, which is designated as PAC6.

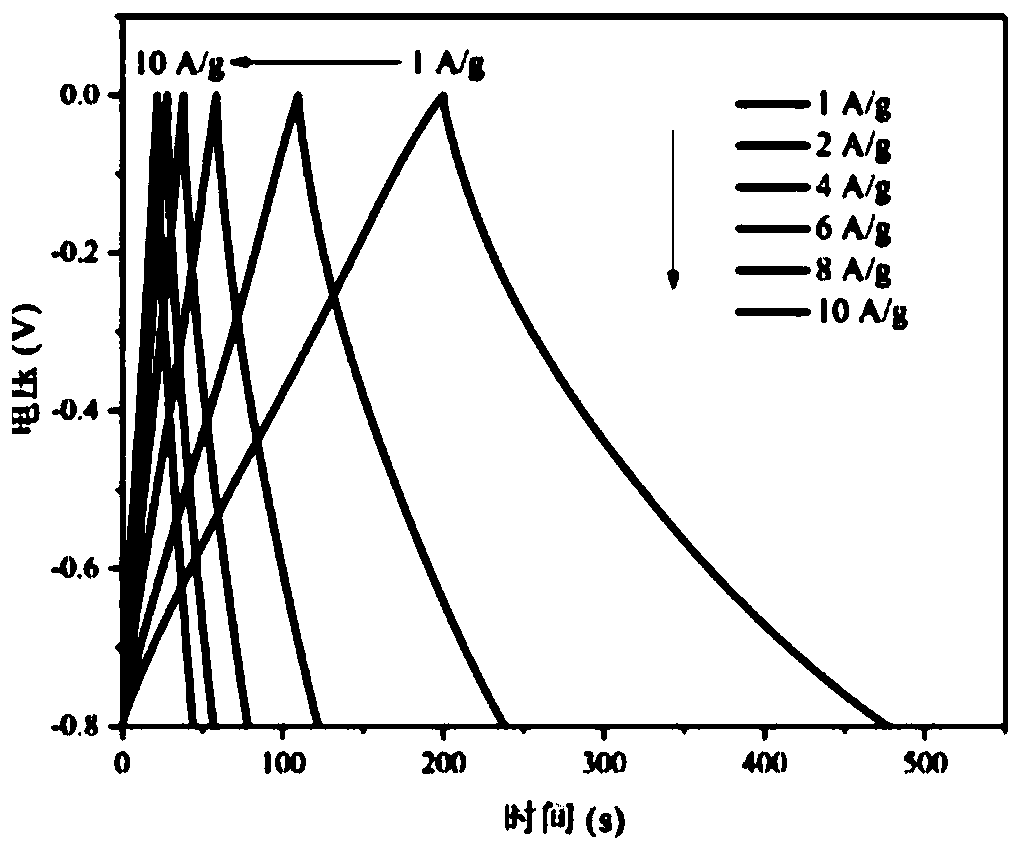

[0049] Electrochemical performance test of PAC6:

[0050] The electrochemical performance of the materials was tested using an electrochemical workstation produced by French Bio-Logic Company. Electrochemical tests were performed using a three-electrode system with Hg / HgO as the reference electrode an...

Embodiment 3

[0054] Utilize sodium alginate to prepare the method for porous activated carbon, the steps are as follows:

[0055] (1) Dissolve 2g sodium alginate in 200mL, 10%wt KHCO with continuous stirring for 1h 3 After being in the aqueous solution, stir slowly for 2h and add 0.5wt% BaCl 2 Solution 100mL, form a non-water-soluble gel, filter with suction, wash with water, wash with ethanol, and dry;

[0056] (2) Under nitrogen atmosphere at 10°C·min -1 The heating rate was increased to 800°C, and then kept for 1h.

[0057] (3) Wash the sample in step (2) with dilute hydrochloric acid (8%), hot water, and ethanol, and dry to prepare porous activated carbon, which is designated as PAC10.

[0058] Sodium alginate solution is stable between pH=5.0 and 11.0, so KHCO 3 The solution is weakly alkaline, so that sodium alginate remains stable during the reaction process, which is conducive to the formation of stable products; at the same time, there are a large number of hydrophilic groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com