Fermented olive wine and preparation method thereof

An olive wine and fermented technology, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, etc., can solve the problems of low juice yield, long fermentation time, and heavy fruit juice taste, etc., to improve Overall quality, reduction of methanol risk, effect of reducing sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Embodiment 1: the preparation method of fermented type olive wine

[0082] 1. Method

[0083] (1) Variety selection and crushing: Sandalwood olives were selected from Huiyuan olives, Changying olives, Sandalwood olives, Laiyuan olives and Zhaoan olives, because the soluble sugar content of sandalwood olive juice is high and browning Light degree, high juice yield, lowest phenolic sugar ratio, strong sweet taste, good storability, and good juice flavor, it is a good variety for making fruit wine. The screening criteria for olive fruit are: the maturity is more than 8 mature, fresh, no rot, no pests, and the soluble sugar content is not less than 1.5%, the total phenol content is not higher than 14.5mg / mL, and the total acid is 5.8g / L of olive fruit. Washing the screened olive fruit with cold water at 8°C and crushing the whole fruit at 15°C to obtain olive pulp.

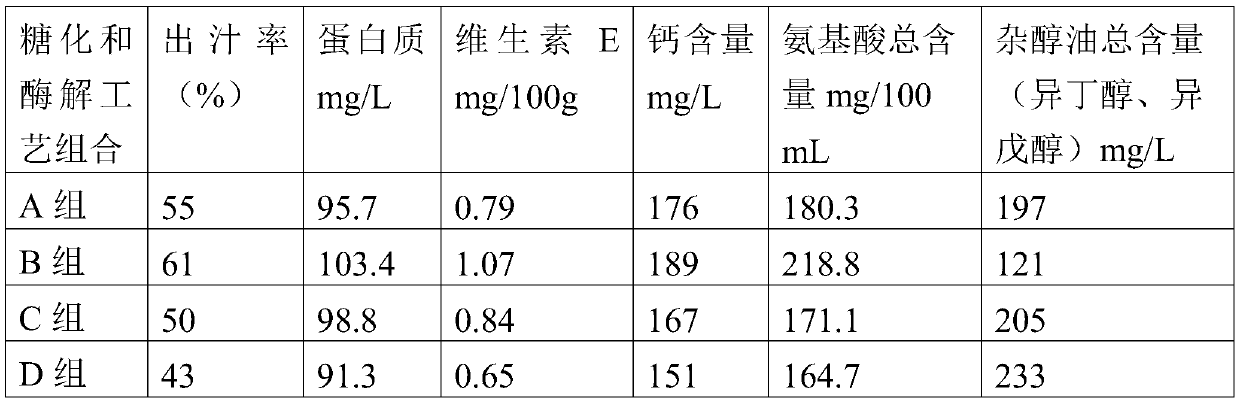

[0084] (2) Saccharification and enzymatic hydrolysis: add 725mg / L (final concentration) Rhizopus esterif...

Embodiment 2

[0091] Embodiment 2: the preparation method of fermented type olive wine

[0092] 1. Method

[0093] (1) kind selection and crushing: with embodiment 1.

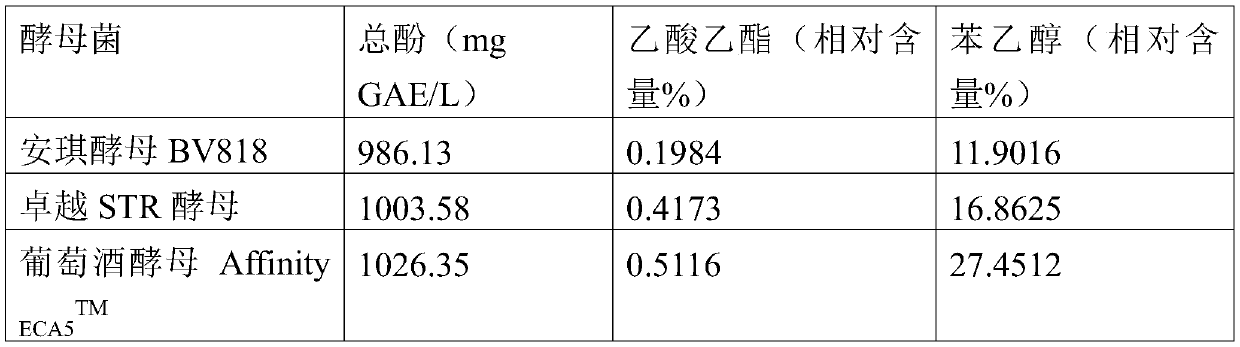

[0094] (2) Saccharification and enzymolysis: add 779mg / L (final concentration) of Rhizopus esterifera to olive pulp and carry out saccharification for 26h at 24.6°C, then lower the temperature of the obtained pulp to 10.8°C and add 13.6mg / L (final concentration) Concentration) Pectinase Process Color, 395mg / L (final concentration) cellobiase for enzymolysis for 5.2h, until the juice yield of fruit juice was 61%, and the enzymatic hydrolysis product was obtained; add 0.20g / L (final concentration) to the enzymatic hydrolysis product Composite carbon-rich bentonite MTR can effectively absorb oily substances in fruit juice, effectively inhibit the growth of long-film bacteria, and ensure the normal fermentation of yeast during fermentation; cellobiase can effectively increase the total flavonoid content of active ingredients,...

Embodiment 3

[0101] Embodiment 3: the preparation method of fermented type olive wine

[0102] 1. Method

[0103] (1) Variety selection and crushing: with embodiment 1, difference is only, the temperature of olive fruit crushing is 8 ℃.

[0104] (2) Saccharification and enzymatic hydrolysis: add 833mg / L (final concentration) Rhizopus esterifera to olive pulp and carry out saccharification for 27h at 25.8°C, then reduce the temperature of the obtained pulp to 11.9°C and add 14.3mg / L (final concentration) Concentration) Pectinase Process Color, 411mg / L (final concentration) cellobiase is enzymatically hydrolyzed, and the juice yield of the fruit juice is 64% after enzymolysis, and the enzymatic hydrolyzate is obtained; 0.26g / L (final concentration) is added to the compound rich Bentonite MTR can effectively absorb oily substances in fruit juice, effectively inhibit the growth of long-film bacteria, and ensure the normal fermentation of yeast during fermentation; cellobiase can effectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com