Preparation method of acid-proof green Pickering emulsifier and Pickering emulsifier thereof

An emulsifier, green technology, applied in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve the problems of the use of green Pickering emulsifiers and other problems, reduce toxicity and skin irritation, and improve environmental friendliness , to achieve long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

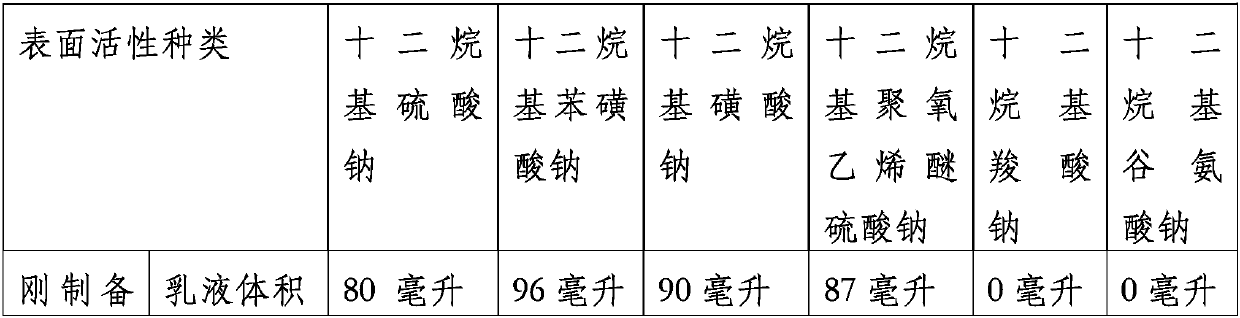

[0029] Sodium lauryl sulfate, sodium dodecylbenzenesulfonate, sodium laurylsulfonate, sodium lauryl polyoxyethylene ether sulfate (polymerization degree: 3), sodium lauryl carboxylate, sodium lauryl glutamate solution is added dropwise to the mass fraction of 50 milliliters is the chitosan acetic acid solution of 0.4% (the concentration of acetic acid is 1 gram / liter, and chitosan average Molecular weight 80000), stirred at room temperature for 1 hour to obtain emulsifier formulations 1-6 respectively. Mix 50 ml of emulsifier formulas 1-6 with 50 ml of isopropyl myristate, adjust to pH = 4, homogenize at 12,000 rpm for 3 minutes at normal temperature and pressure to obtain an emulsion with pH = 4, place it at room temperature, and observe the phase of the emulsion Changes in volume and particle size. The results are shown in Table 1.

[0030] As can be seen from Table 1, under the same preparation conditions, sodium lauryl carboxylate has no effect on the modification of chi...

Embodiment 2

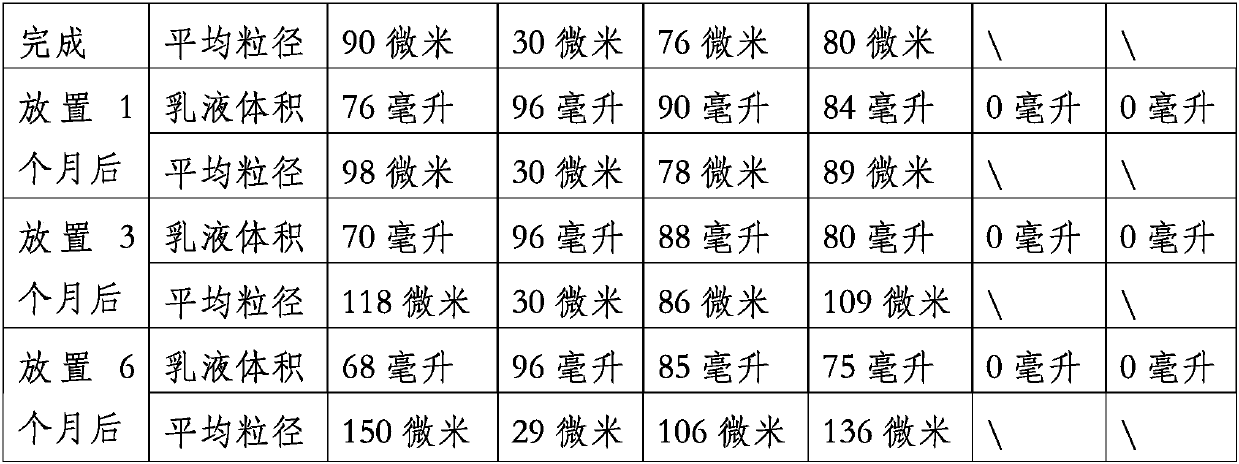

[0035] 50 milliliters of sodium dodecyl sulfate, sodium dodecyl sulfonate and sodium dodecylbenzene sulfonate were added dropwise to 50 milliliters of shells with a mass fraction of 0.4% at a concentration of 1 mmol / L. In the polysaccharide acetic acid solution (acetic acid concentration is 1 g / L), the remaining preparation conditions are the same as in Example 1, adjusted to different pH conditions and placed at room temperature for 3 months, and the changes in the volume and particle size of the emulsion are observed. The results are shown in Table 2. It can be seen that the emulsion prepared by sodium dodecylsulfonate modified chitosan has stronger acid resistance.

[0036] The stability of the emulsion prepared by table 2 surfactant modified chitosan at different pH

[0037]

Embodiment 3

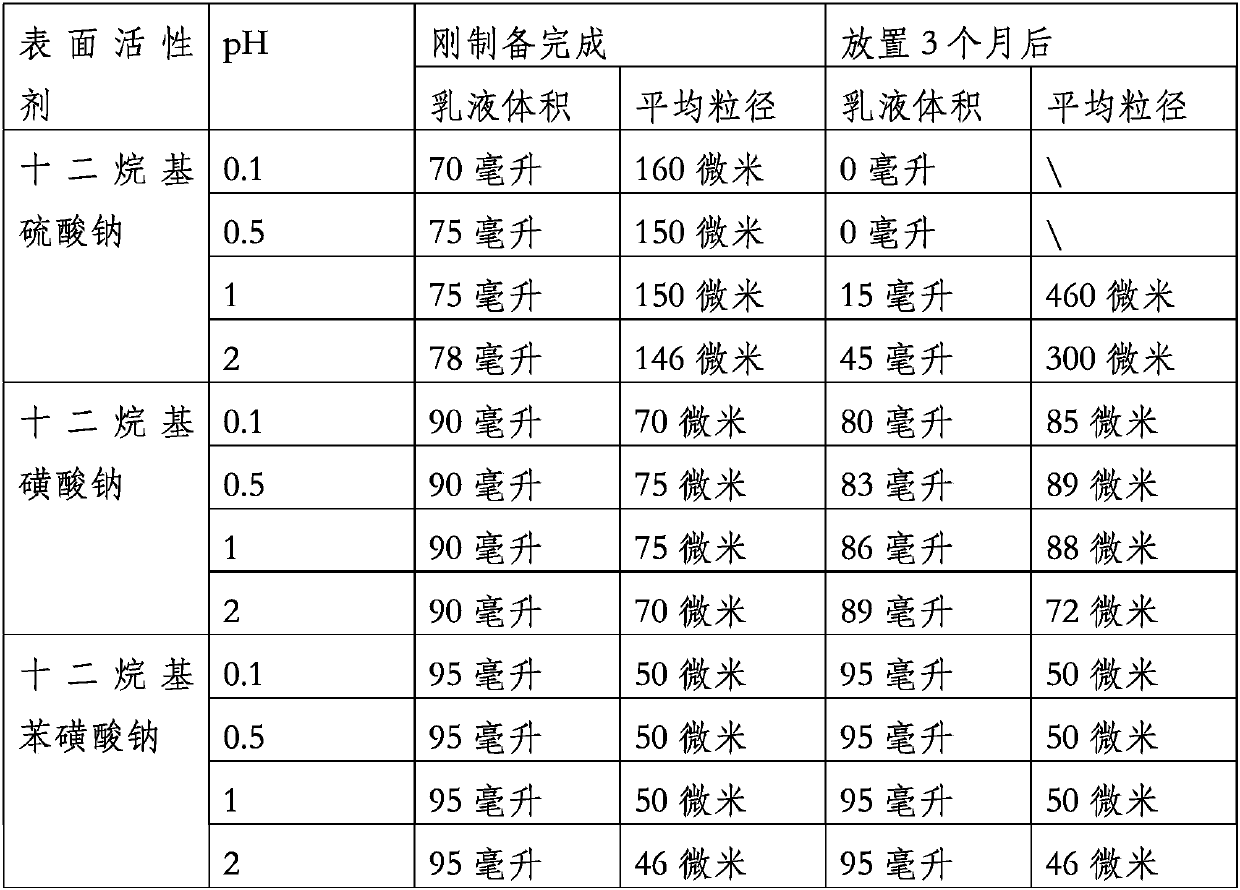

[0039] Drop 50 ml of dodecylbenzenesulfonic acid, sodium octylbenzenesulfonate, sodium hexylbenzenesulfonate, sodium butylbenzenesulfonate, and sodium tetradecylbenzenesulfonate with a concentration of 1 mmol / L respectively. Be added to 50 milliliters of mass fractions and be in the chitosan acetic acid solution (concentration of acetic acid is 1 gram / liter) of 0.4%, all the other preparation conditions are identical with embodiment 1, adjust to pH=0.5, get 40 milliliters of emulsifying agent and 60 milliliters respectively The liquid paraffin was mixed and homogenized at 20,000 rpm for 0.5 min at normal temperature and pressure to obtain an emulsion. Place it at room temperature for 3 months, and observe the changes in emulsion volume and particle size. The results are shown in Table 3. It can be seen that the emulsification effect of chitosan modified by sodium dodecylbenzenesulfonate is the best. If the carbon chain is too long, the solubility of alkylbenzene sulfonate at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com