Dietary fiber compound botanical medicine for treating obesity and hyperlipidemia and preparation method thereof

A technology for dietary fiber and hyperlipidemia, applied in the field of drug development and biological fermentation, can solve the problems of different therapeutic effects, slow onset of therapeutic drugs, and incomplete treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

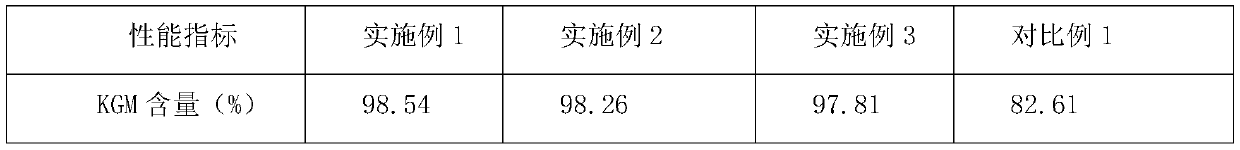

Embodiment 1

[0051] In parts by weight, the dietary fiber compound herbal medicine for treating obesity and hyperlipidemia in the present embodiment includes: 15 parts of wax gourd powder, 20 parts of buckwheat flour, 10 parts of lotus leaf, 6 parts of chia seed oil, 5 parts of angelica, 1 part of Chuanxiong, 8 parts of barley, 8 parts of celery seed powder, 12 parts of konjac glucomannan, 3 parts of cassia, 4 parts of salvia miltiorrhiza, 5 parts of soluble starch, 5 parts of onion extract, 8 parts of hawthorn, 0.5 parts of Polygonum multiflorum share.

[0052] Further, the preparation method of the konjac glucomannan comprises the following steps:

[0053] S11, remove the main buds and root fibers of konjac, soak konjac in a sodium chloride solution with a mass fraction of 0.1-0.5% (preferably 0.3%) for 2-3h, clean, peel, freeze-dry and pulverize to obtain konjac flour;

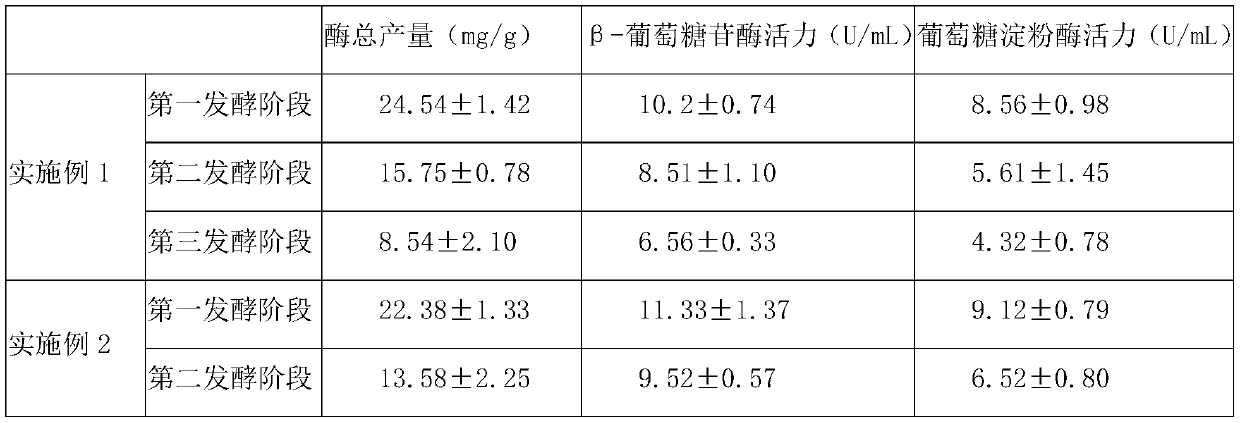

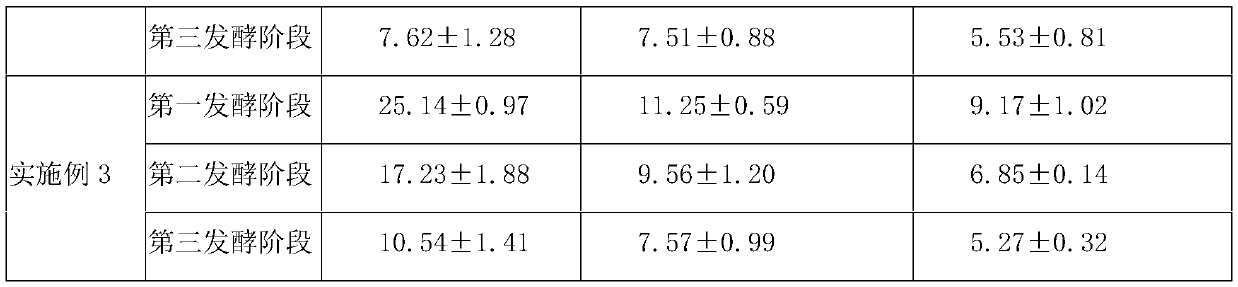

[0054] S12. Inoculate Aspergillus niger species and cellulophagy on independent potato dextrose agar medium respect...

Embodiment 4

[0093] This embodiment also provides a preparation method of the dietary fiber compound herbal medicine for treating obesity and hyperlipidemia described in one of the embodiments 1-3, which includes the following steps:

[0094] S100. Prepare the konjac glucomannan and chia seed oil according to the preparation method described in one of the above-mentioned embodiments 1-3;

[0095] S200. Fully mix the raw materials in one of the parts by weight of Examples 1-3 to obtain a raw material mixture, then place the raw material mixture in a fermenter, add 5-10 times the weight of the raw material mixture (preferably 9 times) deionized water and 0.15-0.25 times (preferably 0.2 times) cellulase and 0.3-0.4 times (preferably 0.35 times) pectinase of the raw material mixture weight, adjust the pH to 6.5-7, And adjust to 35-45°C (preferably 30°C) for fermentation, and separate the liquid fermentation broth after 36-48h (preferably 42h) of fermentation;

[0096] S300. Under the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com