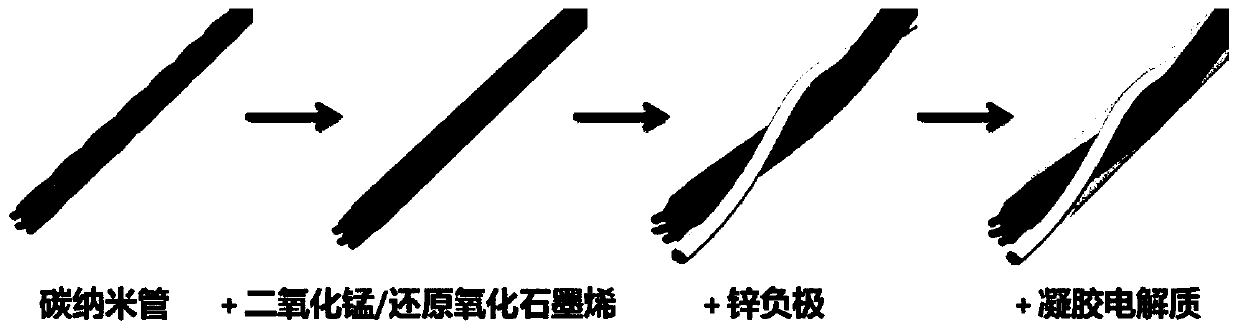

Aqueous zinc ion battery based on manganese dioxide/graphene and preparation method

A zinc-ion battery, manganese dioxide technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve the problems of large internal resistance of the battery, shedding of active materials, and large contact resistance of the positive electrode, so as to improve battery performance and prolong battery life. Life, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

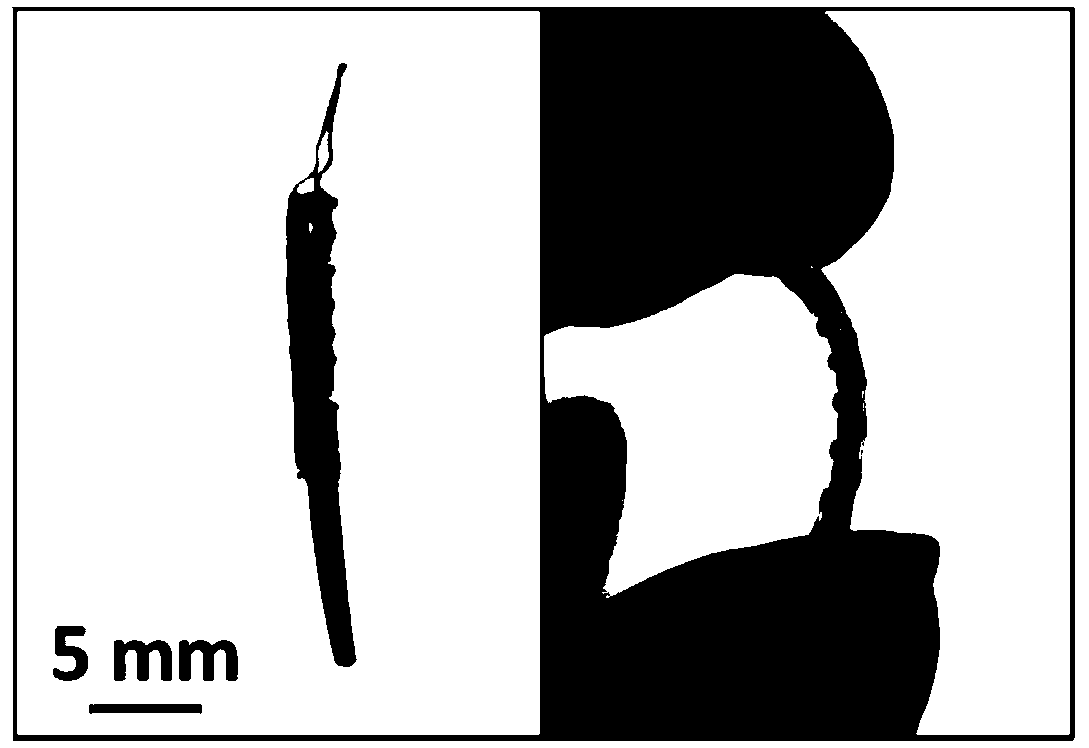

[0021] (1) Preparation of carbon nanotube fiber substrate: Synthesize vertically oriented spinnable multi-walled carbon nanotube arrays by chemical vapor deposition, and then pull out the carbon nanotubes for 5 strands of twisting and stranding, and then twist the strands after twisting Ethanol is uniformly dropped on the carbon nanotube fiber for shaping, and after the ethanol is completely volatilized, the preparation of the carbon nanotube fiber substrate is completed.

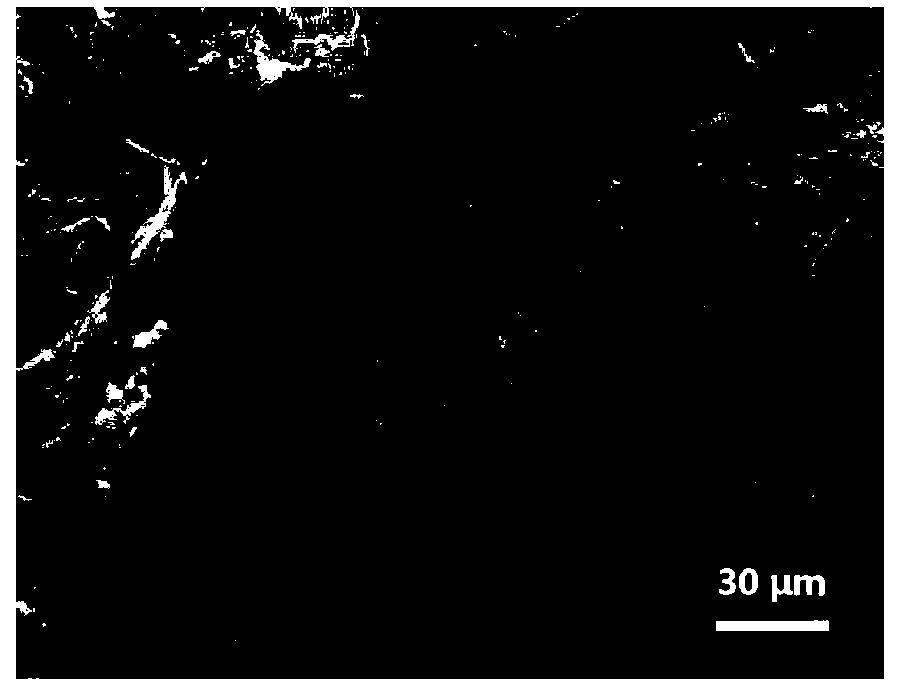

[0022] (2) Preparation of graphene oxide dispersion: 500-mesh graphite powder was thermally expanded at 1000 degrees Celsius for 10 seconds by the expanded graphite method to obtain expanded graphite. The obtained expanded graphite powder is pre-oxidized to obtain pre-oxidized graphene. Afterwards, the pre-oxidized graphene was further oxidized, and the pre-oxidized graphene was added to concentrated sulfuric acid under ice-bath conditions, and potassium permanganate was slowly added to stir the reaction fo...

Embodiment 2

[0028] (1) Preparation of graphene oxide dispersion: 400-mesh graphite powder was thermally expanded at 1000 degrees Celsius for 12 seconds by the expanded graphite method to obtain expanded graphite. The obtained expanded graphite powder is pre-oxidized to obtain pre-oxidized graphene. Afterwards, the pre-oxidized graphene was further oxidized, and the pre-oxidized graphene was added to concentrated sulfuric acid under ice-bath conditions, and potassium permanganate was slowly added to stir the reaction for 3 hours. Then add a large amount of water and a small amount of hydrogen peroxide solution, and finally filter, wash and dilute the product to obtain a graphene oxide dispersion.

[0029] (2) Preparation of manganese dioxide / reduced graphene oxide fibrous positive electrode: take a section of carbon fiber as substrate, graphene oxide dispersion as electrodeposition solution, graphite rod as counter electrode, and saturated calomel electrode as reference electrode, at -1.2 ...

Embodiment 3

[0034] (1) Preparation of carbon nanotube fiber substrate: Synthesize vertically oriented spinnable multi-walled carbon nanotube arrays by chemical vapor deposition, and then pull out the carbon nanotubes for 10 strands of twisting and stranding, and then in the twisted Ethanol is uniformly dropped on the carbon nanotube fiber for shaping, and after the ethanol is completely volatilized, the preparation of the carbon nanotube fiber substrate is completed.

[0035] (2) Preparation of graphene oxide dispersion: 300-mesh graphite powder was thermally expanded at 800 degrees Celsius for 15 seconds by the expanded graphite method to obtain expanded graphite. The obtained expanded graphite powder is pre-oxidized to obtain pre-oxidized graphene. Afterwards, the pre-oxidized graphene was further oxidized, and the pre-oxidized graphene was added into concentrated sulfuric acid under ice bath conditions, and potassium permanganate was slowly added to stir the reaction for 4 hours. Then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com