A diatomite-supported porous bixbyite mn 2 o 3 Catalyst, preparation method and application thereof

A technology of bixbyite and diatomite, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Ideal, restricting large-scale applications, restricting practical applications, etc., to achieve good application prospects, achieve targeted enrichment, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

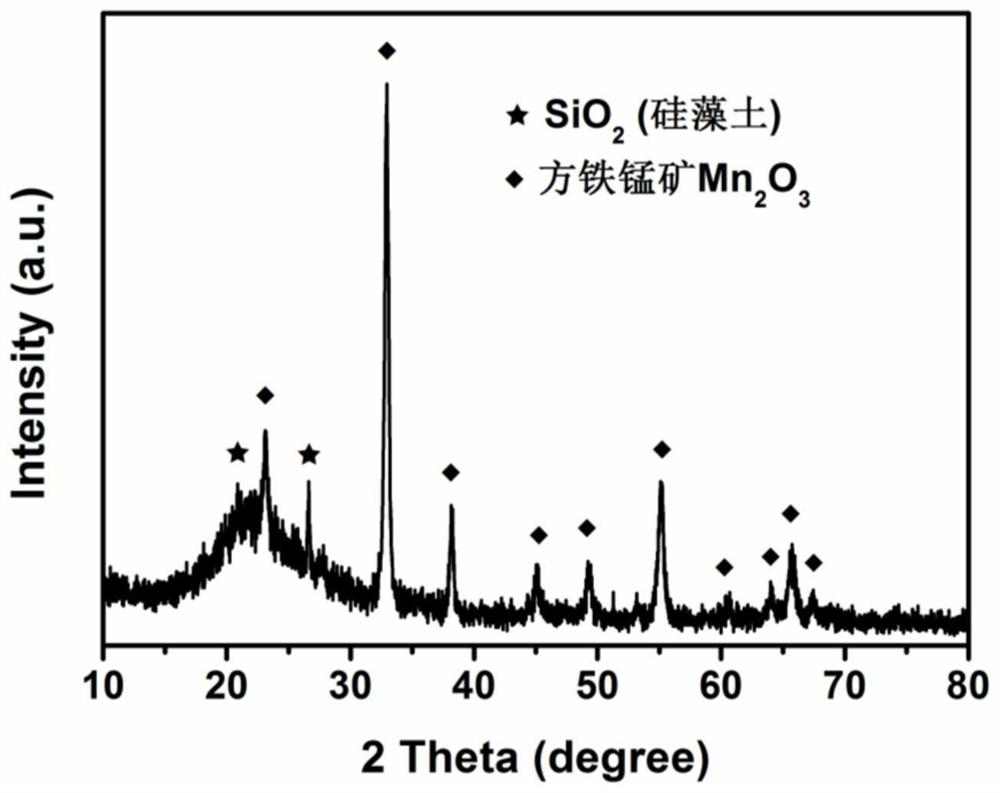

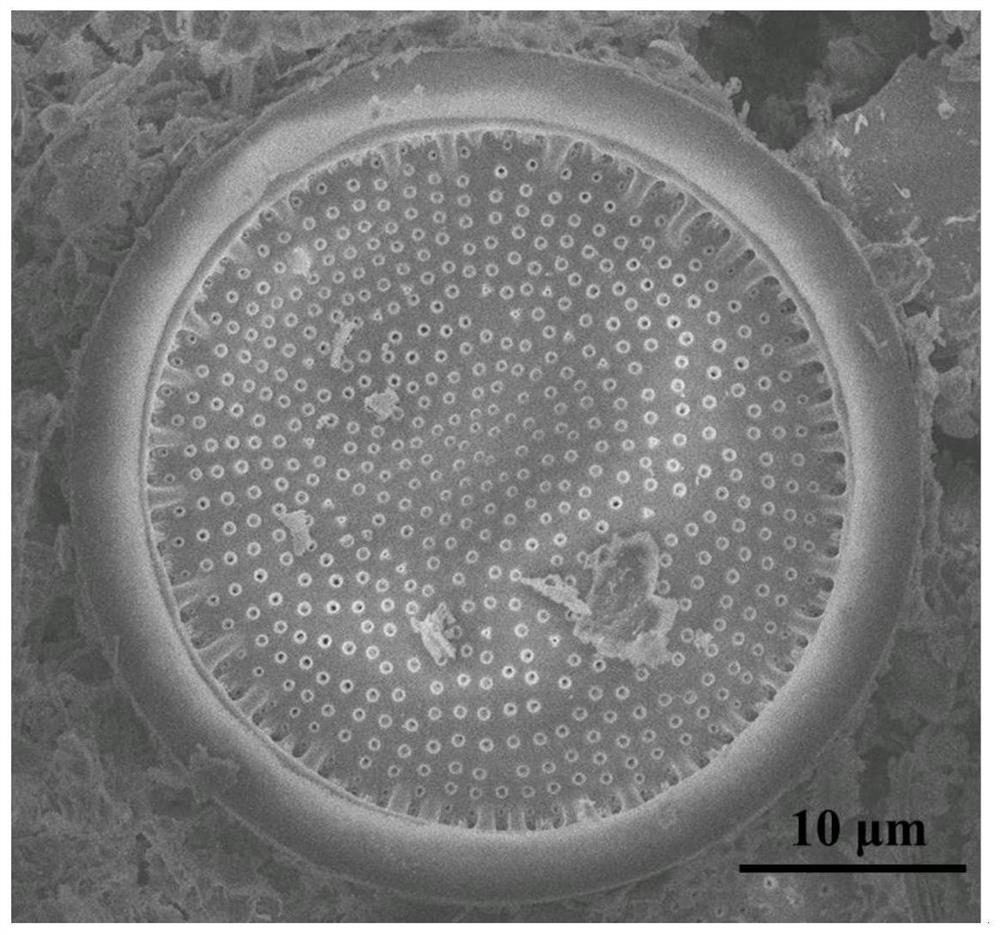

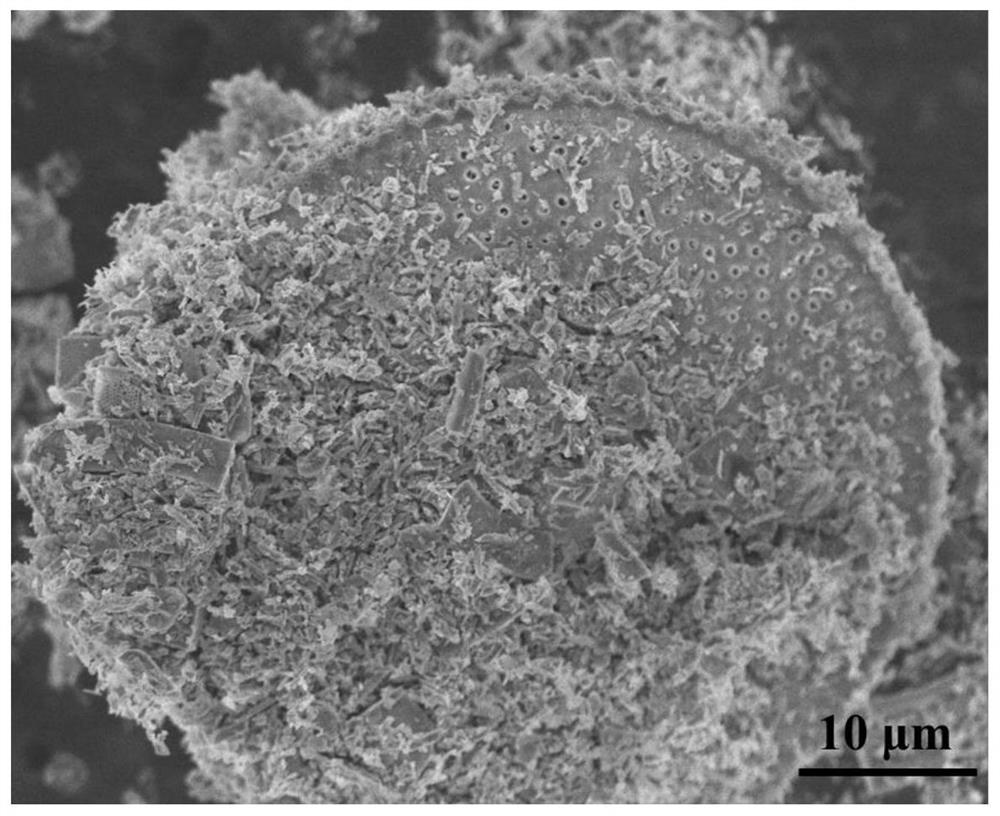

[0027] Add 1.1 mmol of manganese acetate and 0.2 g of diatomite in Linjiang City, Jilin Province (the mass percentage of diatom shells is about 68%) to 40 mL of a mixed solution of isopropanol and glycerin (volume ratio is 3:1), at room temperature After stirring for 3 hours, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor, and the reactor was placed in a constant temperature drying oven at 180° C. for 6 hours. The obtained suspension was naturally cooled to room temperature, centrifuged and washed with absolute ethanol, and the obtained precipitate was placed in a constant temperature drying oven, and dried at 80° C. for 12 hours to obtain manganese alkoxide / diatomaceous earth solid powder. The powder was placed in a muffle furnace, heated to 500 °C at a heating rate of 3 °C / min, and calcined at a constant temperature for 3 hours to obtain diatomite-supported porous bixbyite Mn 2 o 3 (Mn 2 o 3 / diatomaceous earth-500).

[0028] For the Mn pr...

Embodiment 2

[0031] Add 1.1 mmol of manganese acetate and 0.2 g of diatomite in Linjiang City, Jilin Province (the mass percentage of diatom shells is about 68%) to 40 mL of a mixed solution of isopropanol and glycerin (volume ratio is 3:1), at room temperature After stirring for 3 hours, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor, and the reactor was placed in a constant temperature drying oven at 180° C. for 6 hours. The obtained suspension was naturally cooled to room temperature, centrifuged and washed with absolute ethanol, and the obtained precipitate was placed in a constant temperature drying oven, and dried at 80° C. for 12 hours to obtain manganese alkoxide / diatomaceous earth solid powder. The powder was placed in a muffle furnace, heated to 400 °C at a heating rate of 3 °C / min, and calcined at a constant temperature for 3 hours to obtain diatomite-supported porous bixbyite Mn 2 o 3 (Mn 2 o 3 / diatomaceous earth-400).

[0032] The catalytic...

Embodiment 3

[0034] Add 1.1 mmol of manganese acetate and 0.2 g of diatomite in Linjiang City, Jilin Province (the mass percentage of diatom shells is about 68%) to 40 mL of a mixed solution of isopropanol and glycerin (volume ratio is 3:1), at room temperature After stirring for 3 hours, the mixed solution was transferred to a polytetrafluoroethylene-lined reactor, and the reactor was placed in a constant temperature drying oven at 180° C. for 6 hours. The obtained suspension was naturally cooled to room temperature, centrifuged and washed with absolute ethanol, and the obtained precipitate was placed in a constant temperature drying oven, and dried at 80° C. for 12 hours to obtain manganese alkoxide / diatomaceous earth solid powder. The powder was placed in a muffle furnace, heated to 600 °C at a heating rate of 3 °C / min, and calcined at a constant temperature for 3 hours to obtain diatomite-supported porous bixbyite Mn 2 o 3 (Mn 2 o 3 / diatomaceous earth-600).

[0035] The catalytic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com