A polypyrrole-modified nano bismuth oxybromide photocatalytic material and its preparation method and application

A photocatalytic material, bismuth oxybromide technology, applied in the field of photocatalysis, can solve the problems of difficult recovery of inorganic materials, unsatisfactory photocatalytic activity, poor catalytic effect, etc., to improve the ability of photocatalytic degradation of pollutants, excellent visible light Absorptive and conductive properties, effects of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

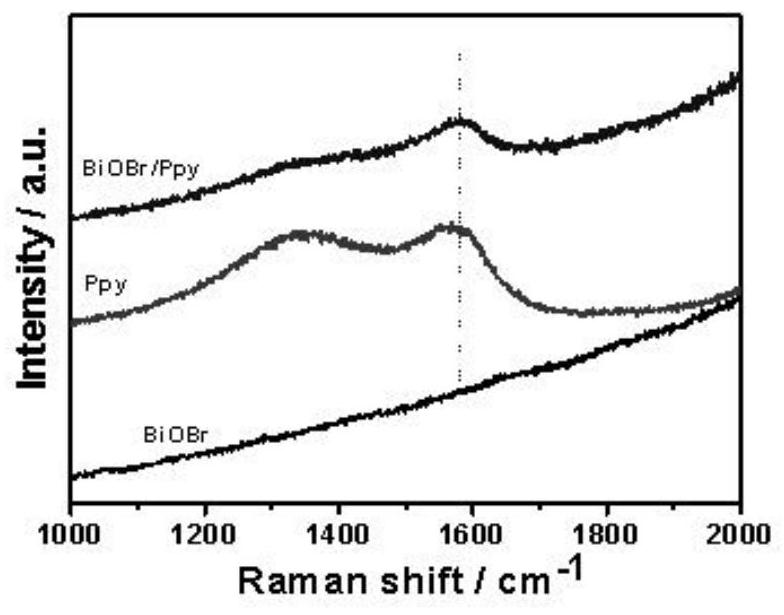

[0036] The present invention also provides a preparation method of the polypyrrole-modified nano-bismuth oxybromide photocatalytic material described in the above technical scheme, comprising the following steps:

[0037] Dispersing flaky nano-bismuth oxybromide in dilute acid aqueous solution containing cetyltrimethylammonium bromide and ammonium persulfate to obtain a dispersion;

[0038] Under an ice bath, after dropping the pyrrole monomer into the dispersion liquid, the in-situ solution polymerization reaction is carried out to obtain the polypyrrole-coated and modified nano-bismuth oxybromide photocatalyst material.

[0039]In the present invention, the preparation method of the flaky nano-bismuth oxybromide is preferably: dissolving bismuth nitrate and potassium bromide in dilute nitric acid aqueous solution, and performing one-step photochemical reaction treatment under simulated sunlight irradiation to obtain flaky nano-bromide Bismuth oxide, the mass fraction of the ...

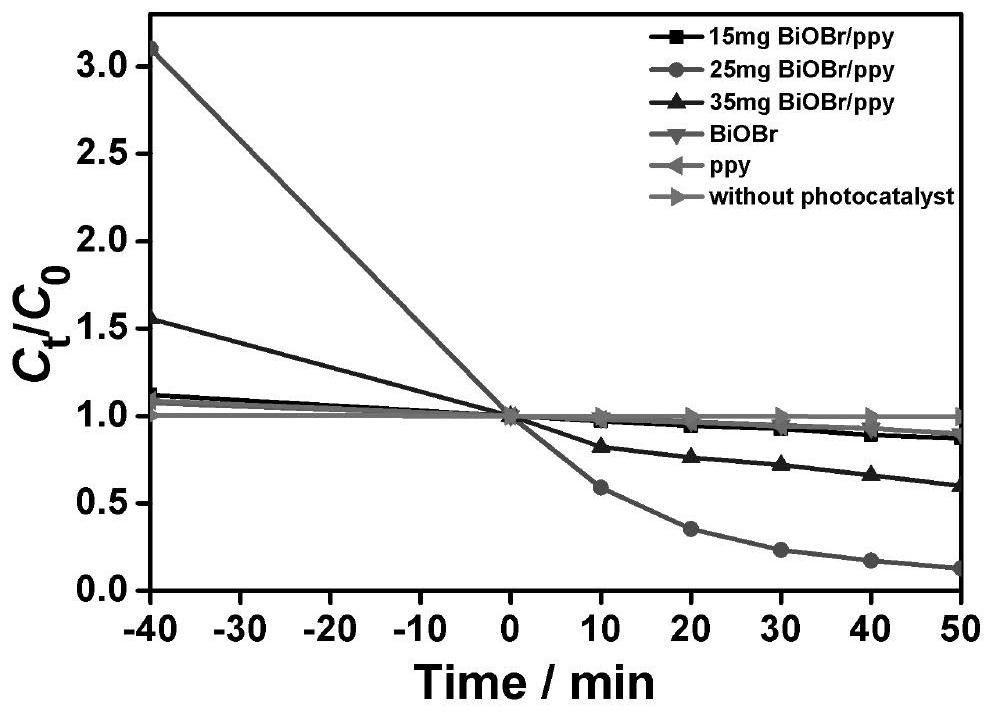

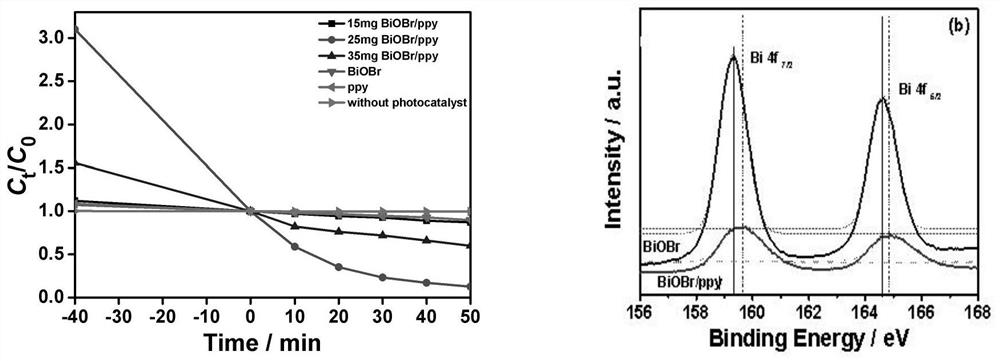

Embodiment 1

[0054] (1) in the 15mL dilute nitric acid that mass fraction is 3%, add 0.8mmol bismuth nitrate pentahydrate and 0.8mmol potassium bromide respectively, after all dissolving, carry out photoreaction under the irradiation of 500W xenon lamp, reaction time is controlled at 0.5h, After the reaction is finished, centrifugation, multiple washings, and vacuum drying are performed to obtain flaky nano-bismuth oxybromide.

[0055] (2) Weigh 0.0182g of cetyltrimethylammonium bromide and 0.0228g of ammonium persulfate, add it to 5mL of dilute hydrochloric acid with a concentration of 1mol / L, after uniform dissolution, mix the 25mg flake bromine obtained by the above reaction Bismuth oxide was dispersed in it, and then 0.35mL of pyrrole monomer was added dropwise in an ice bath, and then reacted and polymerized at room temperature (25°C) for 18h. The product was centrifuged, washed and vacuum-dried to obtain a brown polypyrrole-modified nano bromide oxide Bismuth composite (BiOBr / Ppy). ...

Embodiment 2

[0064] (1) in the 15mL dilute nitric acid that mass fraction is 3%, add 0.8mmol bismuth nitrate pentahydrate and 0.8mmol potassium bromide respectively, after all dissolving, carry out photoreaction under the irradiation of 500W xenon lamp, reaction time is controlled at 0.5h, After the reaction is finished, centrifugation, multiple washings, and vacuum drying are performed to obtain flaky nano-bismuth oxybromide.

[0065] (2) Weigh 0.0182g of cetyltrimethylammonium bromide and 0.0228g of ammonium persulfate, add 5mL of dilute hydrochloric acid with a concentration of 1mol / L, after uniform dissolution, mix the 15mg flake bromine obtained by the above reaction Bismuth oxide was dispersed in it, and then 0.35mL of pyrrole monomer was added dropwise in an ice bath, and then reacted and polymerized at room temperature (25°C) for 18h. The product was centrifuged, washed and vacuum-dried to obtain a brown polypyrrole-modified nano bromide oxide Bismuth composite material, named BiOB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com