A kind of preparation method of magnetic fluid for sealing with high resistance to magnetic sedimentation under strong magnetic field

A magnetic fluid and sedimentation technology, applied in the direction of magnetic objects, magnetic liquids, magnetic materials, etc., can solve the problem of low anti-magnetic sedimentation of magnetic fluids, achieve a strong chemical bond system, reduce interaction, and solve anti-magnetic sedimentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

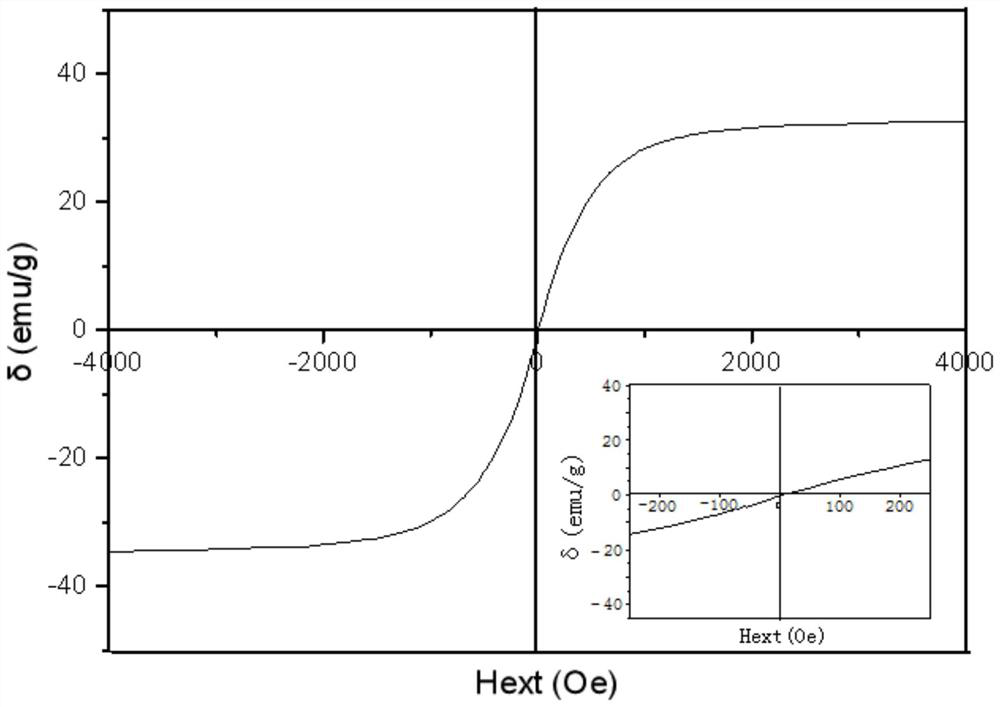

[0043] Embodiment 1: The preparation method of the magnetic fluid for sealing with high resistance to magnetic sedimentation under the condition of strong magnetic field of this embodiment is carried out according to the following steps:

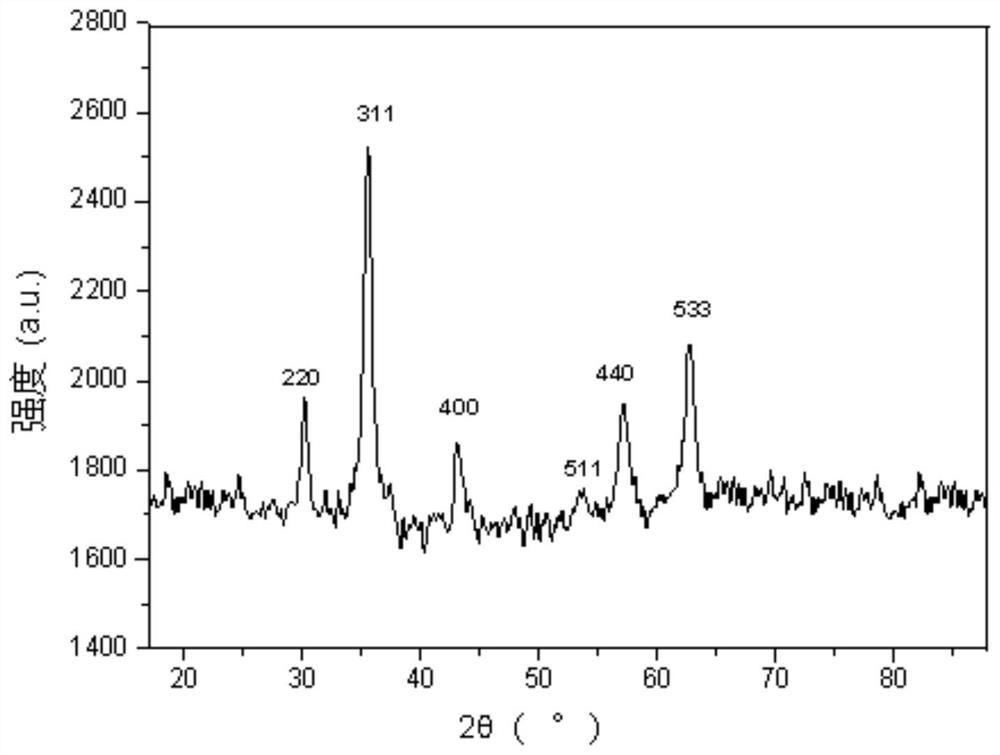

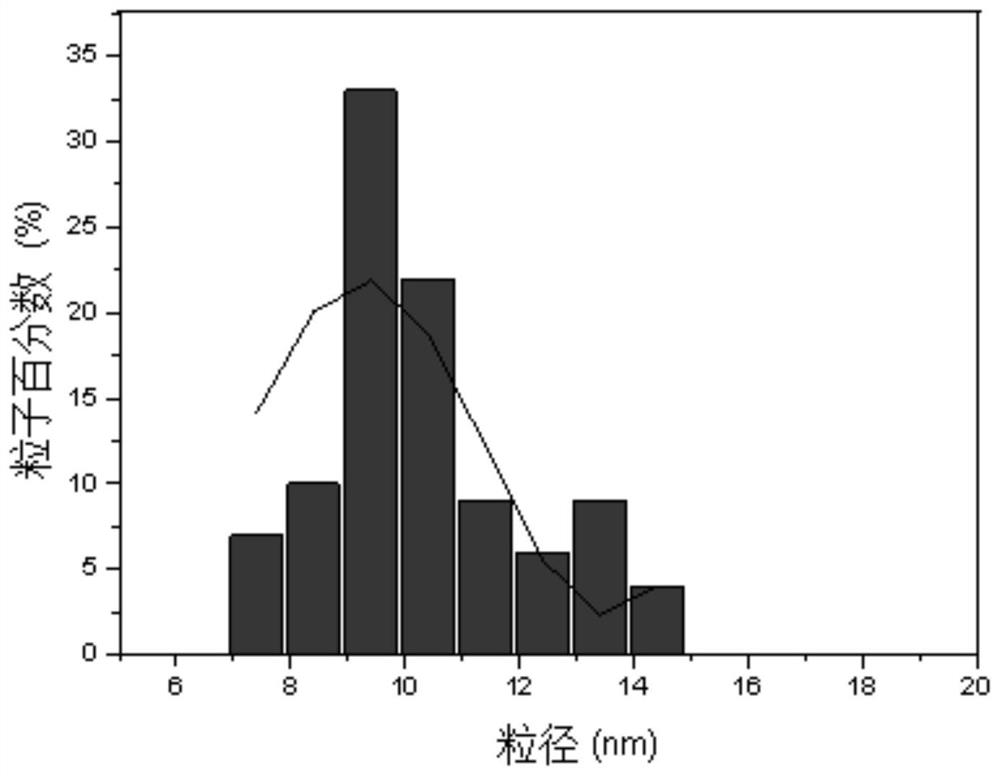

[0044] 1. Preparation of Fe with a particle size of 5 to 20 nanometers 3 o 4 Magnetic powder:

[0045] 2. Weighing nano-Fe 3 o 4 powder, first antioxidant, first dispersant, second antioxidant, second dispersant, metal deactivator, viscosity modifier and synthetic hydrocarbon base oil;

[0046] Among them, the first antioxidant is barium petroleum sulfonate, dodecenylsuccinic acid, 4,4'-dioctyl diphenylamine, dodecenylsuccinic acid, zinc diisooctyl dithiophosphate or high Alkali sulfurized calcium alkylphenate;

[0047] The first dispersant is: polyisobutylene monosuccinimide, non(octyl) phenol polyoxyethylene ether, diphenyl p-isooctyl phosphate, fatty alcohol polyoxyethylene ether sodium sulfate, ash-free polyisobutenyl Succinimide o...

specific Embodiment approach 2

[0055] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the particle size is 5-20 nanometers of Fe 3 o 4 The preparation method of magnetic powder is as follows:

[0056] (1) Nitrogen gas is passed into the NaOH aqueous solution of 25%~30% by mass percent to carry out oxygen removal and continues to pass into nitrogen gas to form a protective atmosphere, and the FeCl 2 with FeCl 3 The mixed aqueous solution is added dropwise to the NaOH aqueous solution. After the dropwise addition, the temperature is raised to 60-85°C, and the surfactant is added dropwise. After the surfactant is added dropwise, the reaction is stirred at 80-85°C for 20-40 minutes , during the reaction process, continuously feed nitrogen to carry out atmosphere protection to obtain a suspension;

[0057] where FeCl 2 with FeCl 3 FeCl in the mixed aqueous solution 2 with FeCl 3 The mass ratio is 1:(1.5~2.5);

[0058] FeCl 2 with FeCl 3 I...

specific Embodiment approach 3

[0062] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the surfactant described in step (1) is oleic acid, (Z)-9-octadecenoic acid sodium, ethoxylated alkyl fat Alcohol polyoxyethylene ether, sodium dodecylbenzene sulfonate (DBSA), sodium tetrapropylene benzene sulfonate and barium methylene dinaphthalene sulfonate or a combination of several; other and specific Embodiment 2 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com