Fiber array ultra-black material and preparation method thereof

An ultra-black material and array technology, applied in fiber processing, dyeing, physical processing, etc., can solve the problems of carbon tube array preparation temperature growth, limited practical application, poor adhesion of the array structure and large-area transfer, etc., and achieve excellent light absorption. performance, reflection reduction, stray light suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The invention provides a fiber array ultra-black material and a preparation method thereof, the preparation method comprising the following steps:

[0073] The first step, fiber pretreatment: the fiber filaments are cut into a certain length of chopped fibers by a fiber cutter, and the chopped fibers are sieved by a mechanical vibrating screen for 2 hours. Chopped fibers pass through screens of different meshes, and fibers with similar lengths stay in the same mesh. After sieving, the chopped fibers have high consistency in length and good dispersion. The mesh numbers of the sieves are respectively: 50 mesh, 100 mesh, 200 mesh, 300 mesh and 400 mesh. In particular, for nylon fibers, due to their inherently transparent and colorless, poor insulation and electrical conductivity, they need to be dyed black and electrophoresis before sieving; the black dyeing process uses nigrosine acid dyes to dye colorless and transparent nylon fibers. Turn into black; Electrodeposition ...

Embodiment 1

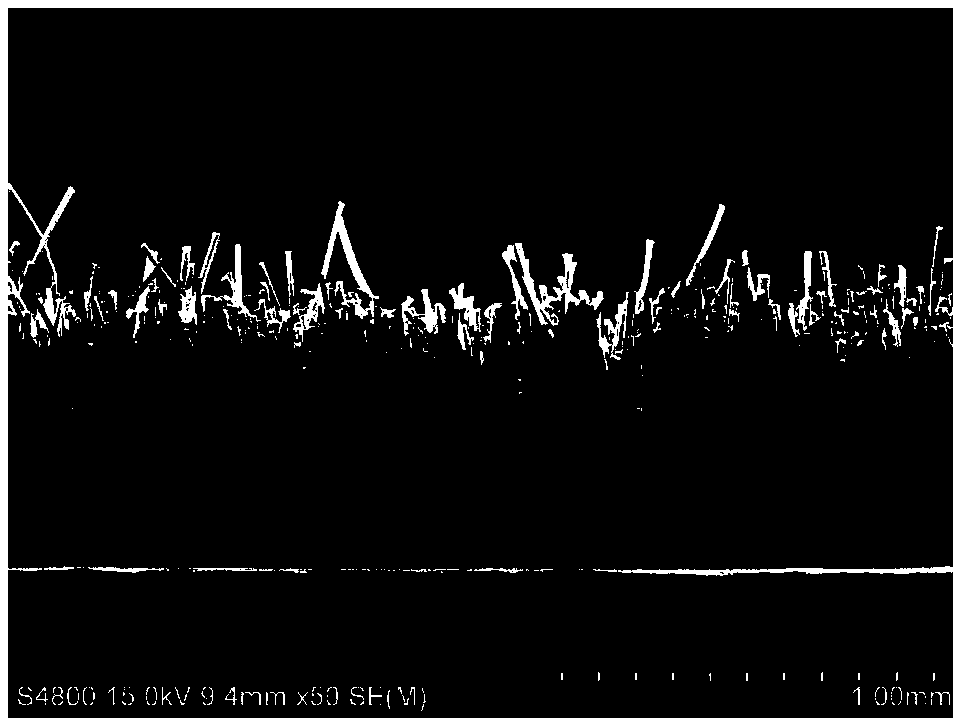

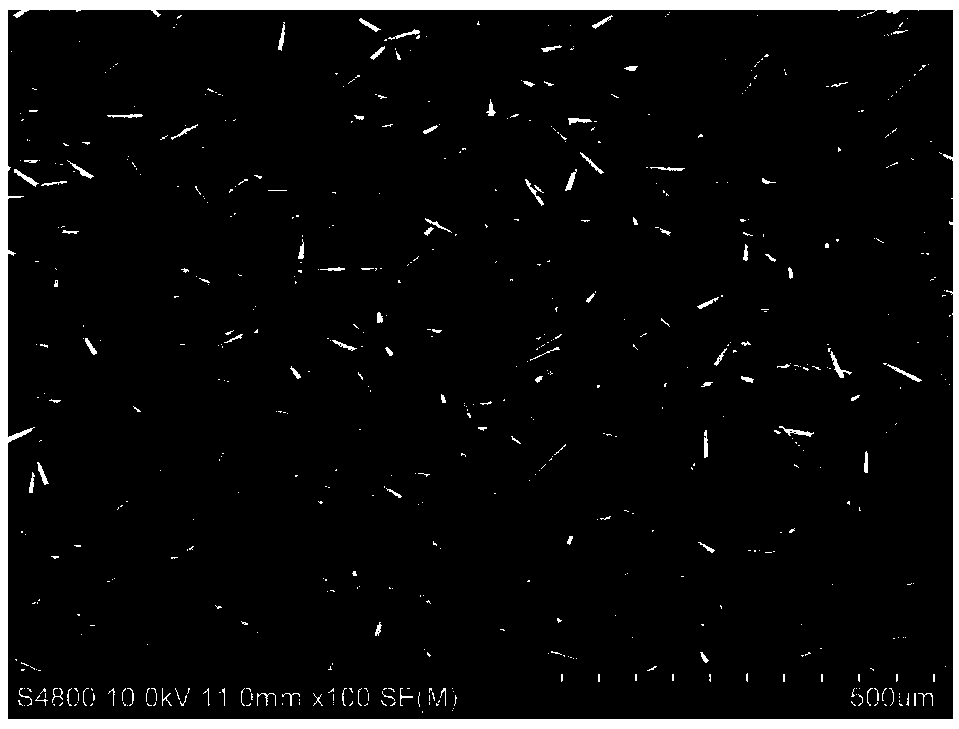

[0081] Put black nylon chopped fibers with a length of 0.6mm in a mechanical vibrating sieve and sieve for 2 hours. Take out 1g and evenly disperse it on the metal plate under the high-voltage electrostatic device; cut the aluminum foil substrate of 15×15cm, and stick it on the surface of the upper metal plate with tape, clean the surface of the aluminum foil with ethanol and acetone respectively; weigh 1g of acrylate adhesive Glue, use SZQ film applicator to evenly coat the surface of the substrate, the wet film thickness is 250μm; close the electrostatic flocking device, adjust the distance between the plates to 10cm, turn on the high-voltage DC power supply, adjust the voltage to 40kV to prepare fiber arrays, and the power-on time is 20s; Take out the prepared fiber array together with the flat electrode and put it into a vacuum oven, and cure it in a vacuum at 80°C for 1 hour; use compressed air to comb the surface of the cured fiber array through a nozzle, and use scotch t...

Embodiment 2

[0084] The polyacrylonitrile-based carbon fiber with a length of 0.4 mm was placed in a mechanical vibrating sieve for 2 hours, and the mesh numbers of the mesh were as follows: 50 mesh, 100 mesh, 200 mesh, 300 mesh and 400 mesh; the fiber samples on the 300 mesh mesh were Take out 1g and evenly disperse it on the lower plate of the high-voltage electrostatic device; cut a 20×20cm carbon fiber composite material plate, use double-sided tape to flatten the carbon fiber plate on the surface of the upper plate, clean the surface with ethanol and acetone respectively; weigh 1g Epoxy adhesive, use a wire rod to evenly coat the surface of the substrate, the wet film thickness is 200μm; set up an electrostatic flocking device, adjust the distance between the plates to 10cm, and put a nylon screen frame in parallel between the plates, the mesh size 100 mesh; turn on the high-voltage DC power supply, adjust the voltage to 30kV to prepare fiber arrays, and power on for 20s; put the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com