Irradiation cross-linking low-smoke halogen-free sheath material for photovoltaic cable, and preparation method thereof

A low-smoke halogen-free sheathed, photovoltaic cable technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc. Poor performance, short service life and other problems, to achieve the effect of reducing high crystallinity, improving light transmittance, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

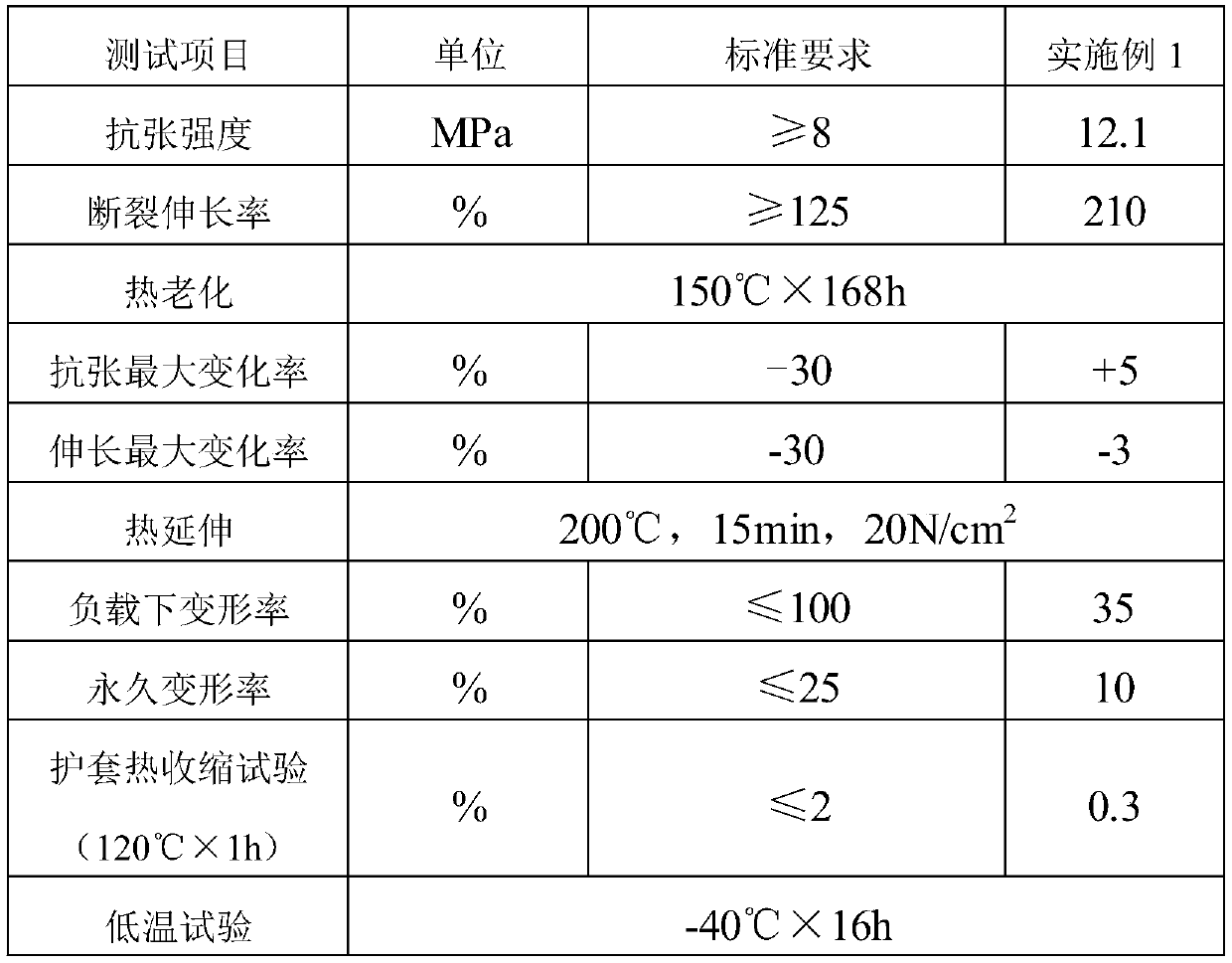

Embodiment 1

[0035] Weigh each component, take by weight and control the properties of each component to meet:

[0036] 20 parts of ethylene-vinyl acetate copolymer, vinyl acetate content 28%, melt index (190°C, 2.16kg) 6g / 10min, ethylene-vinyl acetate copolymer can effectively reduce high crystallinity, improve flexibility and impact resistance compatibility, filler compatibility and heat-sealing properties, ensuring good mechanical properties and processing properties of the sheath;

[0037]10 parts of EPDM rubber, Mooney viscosity (ML1+4, 125°C) 70, ethylene content 50%, the third monomer is ethylidene-norbornene, content 5%, EPDM rubber has oxidation resistance, The anti-ozone and anti-erosion properties make the sheath have good chemical properties and prolong the service life;

[0038] 8 parts of high-density polyethylene, density 0.948g / cm3, melt index (190°C, 2.16kg) 5-10g / 10min, has good mechanical properties, anti-seepage performance, heat resistance and sunlight aging resistanc...

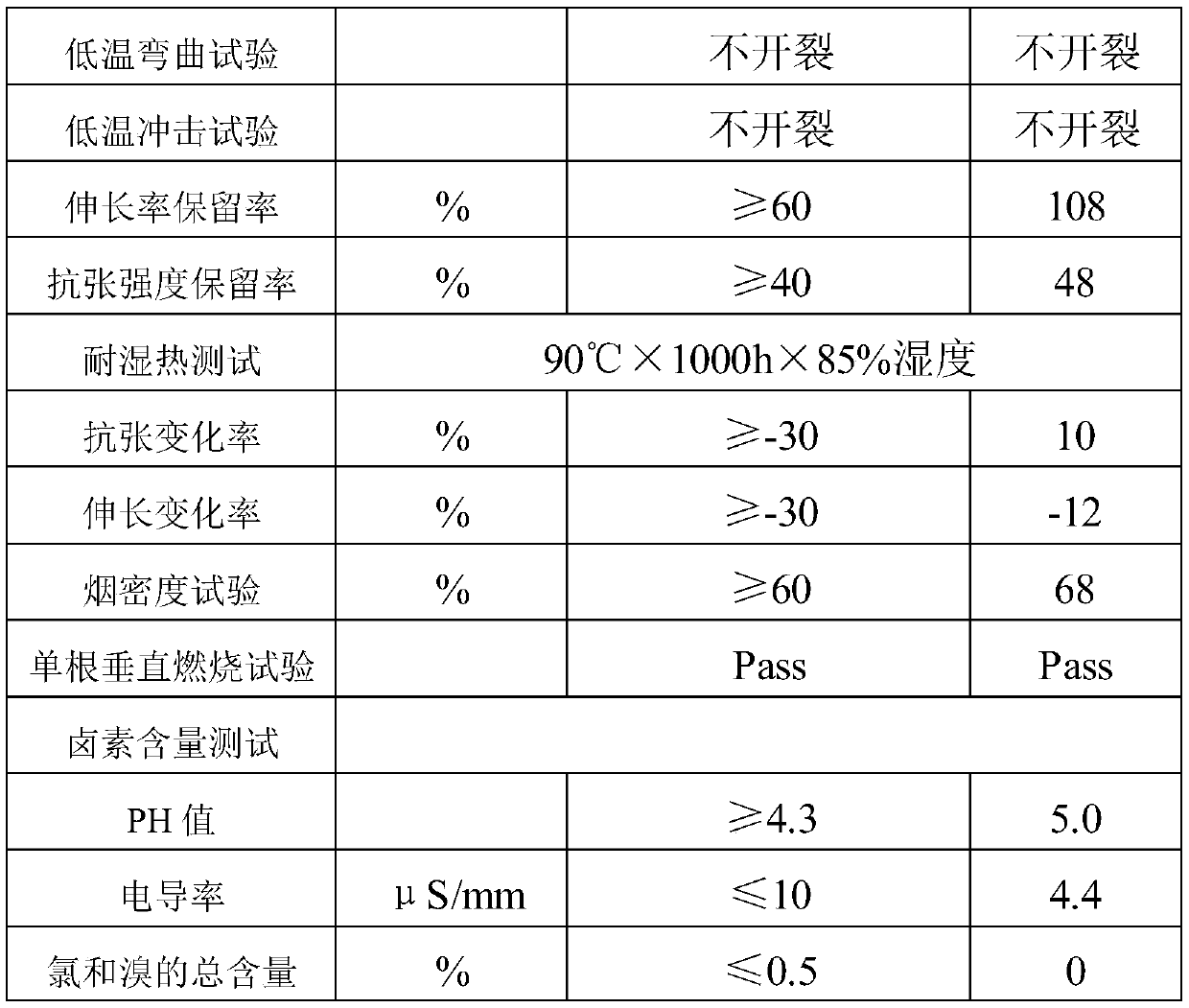

Embodiment 2

[0054] Weigh each component, take by weight and control the properties of each component to meet:

[0055] 18 parts of ethylene-vinyl acetate copolymer, vinyl acetate content 26%, melt index (190°C, 2.16kg) 3g / 10min;

[0056] 12 parts of EPDM rubber, Mooney viscosity (ML1+4, 125°C) 70, ethylene content 50%, the third monomer is ethylidene-norbornene, content 5%;

[0057] 7 parts of high-density polyethylene, density 0.948g / cm3, melt index (190°C, 2.16kg) 6g / 10min;

[0058] Silane coupling agent surface modified aluminum hydroxide 20 parts, mesh number 8000 mesh;

[0059] Silane coupling agent surface modified magnesium hydroxide 25 parts, mesh number 8000 mesh;

[0060] 5 parts of aluminum diethyl hypophosphite, particle size D50≤10μm, decomposition temperature (TGA thermal weight loss 1%): >320°C;

[0061] 2.5 parts of maleic anhydride grafted polyethylene, the grafting rate is 1%;

[0062] 1.5 parts of trimethylolpropane triacrylate;

[0063] Tetrakis[β-(3,5-di-tert-but...

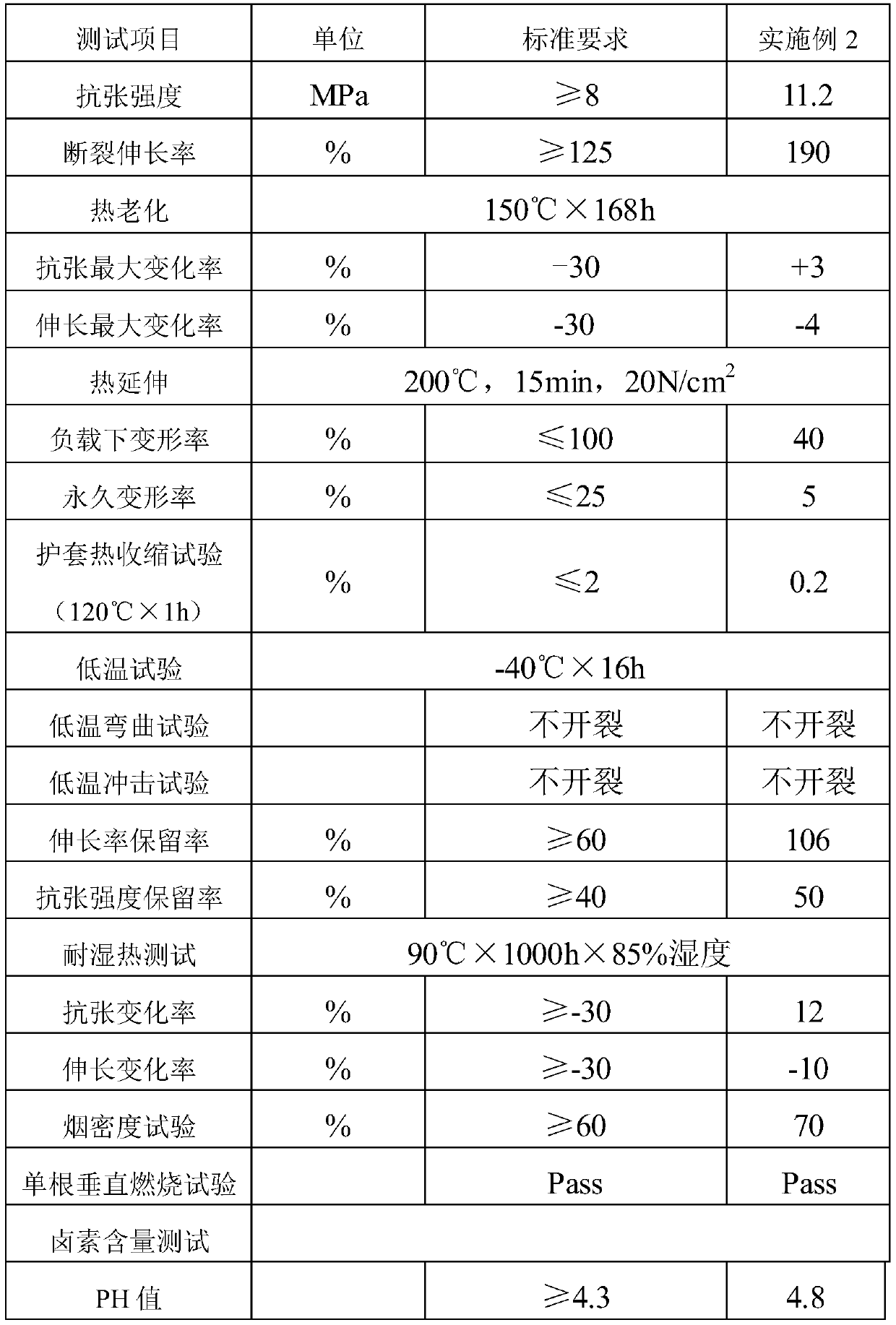

Embodiment 3

[0072] Weigh each component, take by weight and control the properties of each component to meet:

[0073] 15 parts of ethylene-vinyl acetate copolymer, vinyl acetate content 28%, melt index (190°C, 2.16kg) 6g / 10min;

[0074] 15 parts of EPDM rubber, Mooney viscosity (ML1+4, 125°C) 70, ethylene content 50%, the third monomer is ethylidene-norbornene, content 5%;

[0075] 9 parts of high-density polyethylene, density 0.948g / cm3, melt index (190°C, 2.16kg) 8g / 10min;

[0076] 18 parts of silane coupling agent surface modified aluminum hydroxide, mesh number 8000 mesh;

[0077] Silane coupling agent surface modified magnesium hydroxide 25 parts, mesh number 8000 mesh;

[0078] 7 parts of aluminum diethyl hypophosphite, particle size D50≤10μm, decomposition temperature (TGA thermal weight loss 1%): >320°C;

[0079] 2 parts of maleic anhydride grafted polyethylene, the grafting rate is 1%;

[0080] 1.5 parts of trimethylolpropane triacrylate;

[0081] 4,4'-thiobis(6-tert-butyl-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com