Organic industrial tail water treatment method based on ozone oxidation and biodegradation near-field coupling system

A biodegradation, near-field coupling technology, applied in biological water/sewage treatment, oxidized water/sewage treatment, aerobic process treatment, etc., can solve problems such as secondary pollution and reduction, and achieve damage reduction, avoid accumulation, reduce Effects of Treating Wastewater Toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

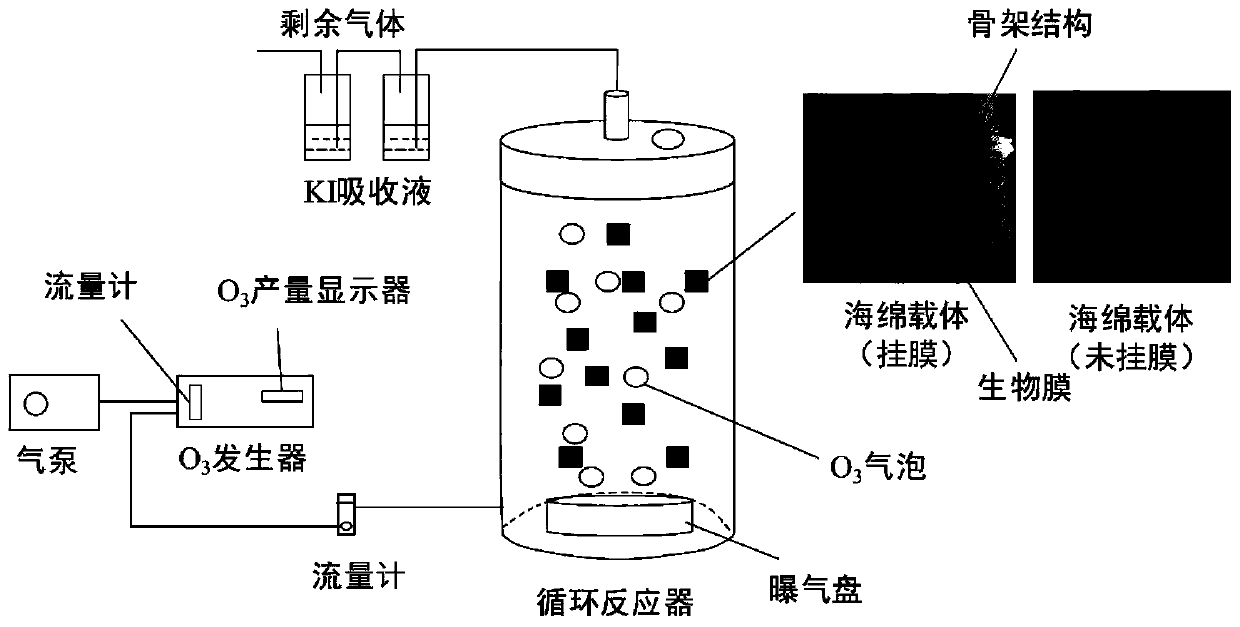

[0028] Embodiment 1: using porous sponge as carrier to cultivate biofilm

[0029] Take the sludge from the aerobic pool of the sewage treatment plant, settle for 1-3 hours to make the sludge layer and pour off the supernatant, and aerate for 1-3 days to activate the sludge; then soak the sponge carrier in the activated sludge and stir properly And continue to aerate for 1-3 days to fully absorb activated sludge on the pores and skeleton of the sponge carrier; then transfer the sponge carrier adsorbed with activated sludge to a completely mixed continuous flow circulation reactor for further cultivation, and supplement a certain amount of treated Industrial waste water is used as nutrient substance, make COD:N:P=100:5~10:1~5, inoculate and cultivate for 7-10d.

[0030] The sponge carrier is a polyurethane sponge, the polyurethane sponge has a porous honeycomb structure, the pore size is 0.1-0.3mm, and the porosity is about 85-90%, and the polyurethane sponge is a cube with a si...

Embodiment 2-4

[0032] The effluent quality of coking wastewater from a coking plant is shown in Table 1 below:

[0033] Table 1

[0034] project scope unit pH 7.5-8.0 COD 500-600 mg / L BOD 5

40-80 mg / L TN 70.8 mg / L Total phenols 56.7 mg / L Cl -

790 mg / L Chroma 600 times SS 74 mg / L

[0035] *COD stands for Chemical Oxygen Demand (ChemicalOxygenDemand, COD);

[0036] *BOD 5 Indicates the five-day biochemical oxygen demand (BiochemicalOxygenDemand, BOD5);

[0037] *TN means total nitrogen in water (TotalNitrogen, TN);

[0038] *SS means suspended solids concentration (Suspended solid, SS).

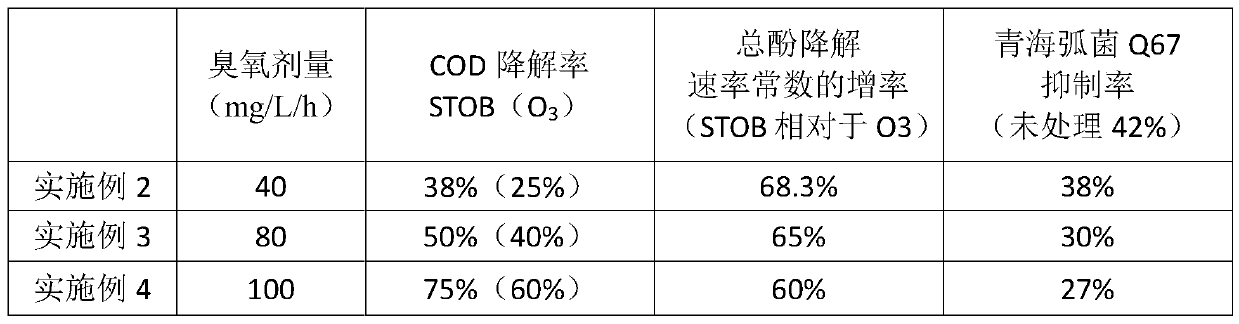

[0039] Take 500mL coking wastewater effluent in Table 1 and add it to the ozonation-biodegradation near-field coupling reactor, and add 2000 sponge carriers loaded with biofilm in Example 1 at the same time. Turn on the air pump and the ozone generator, and adjust and control the ozone dosage to be 40, 80, and 100 mg / ...

Embodiment 5-7

[0044] The tail water quality of a pharmaceutical factory is shown in Table 3 below:

[0045] table 3

[0046] project scope unit COD 180-200 mg / L BOD 5

61 mg / L Chroma 60 times Turbidity 19.9 NTU SS 0.079 mg / L Ammonia nitrogen 39.21 mg / L TDS 11.18 ppt salinity 13.13 psu Conductivity 22.77 ms / cm Resistivity 43.83 ohm-cm

[0047] *COD stands for Chemical Oxygen Demand (ChemicalOxygenDemand, COD);

[0048] *BOD 5 Indicates the five-day biochemical oxygen demand (BiochemicalOxygenDemand, BOD 5 );

[0049] *SS means suspended solids concentration (Suspended solid, SS);

[0050] *TDS means total dissolved solids (Total dissolved solids, TDS).

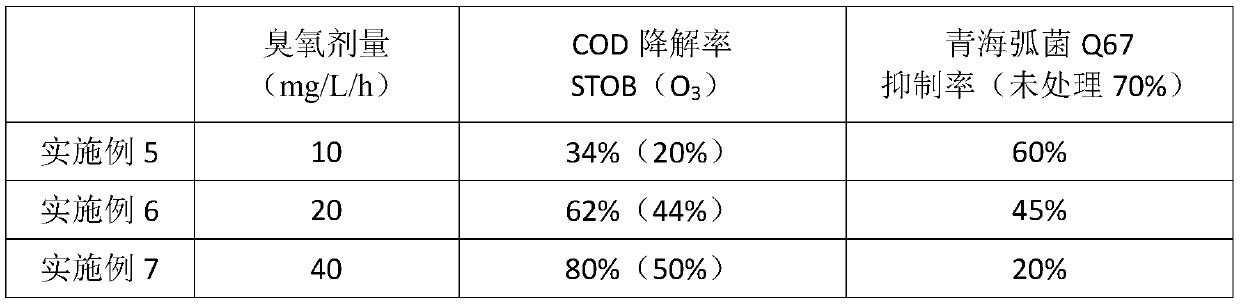

[0051] Get the pharmaceutical factory tail water 500mL in Table 3 and join in the reactor of the present invention, add 2000 sponge carriers that are loaded with biofilm simultaneously. Turn on the air pump and the ozone generator, adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com