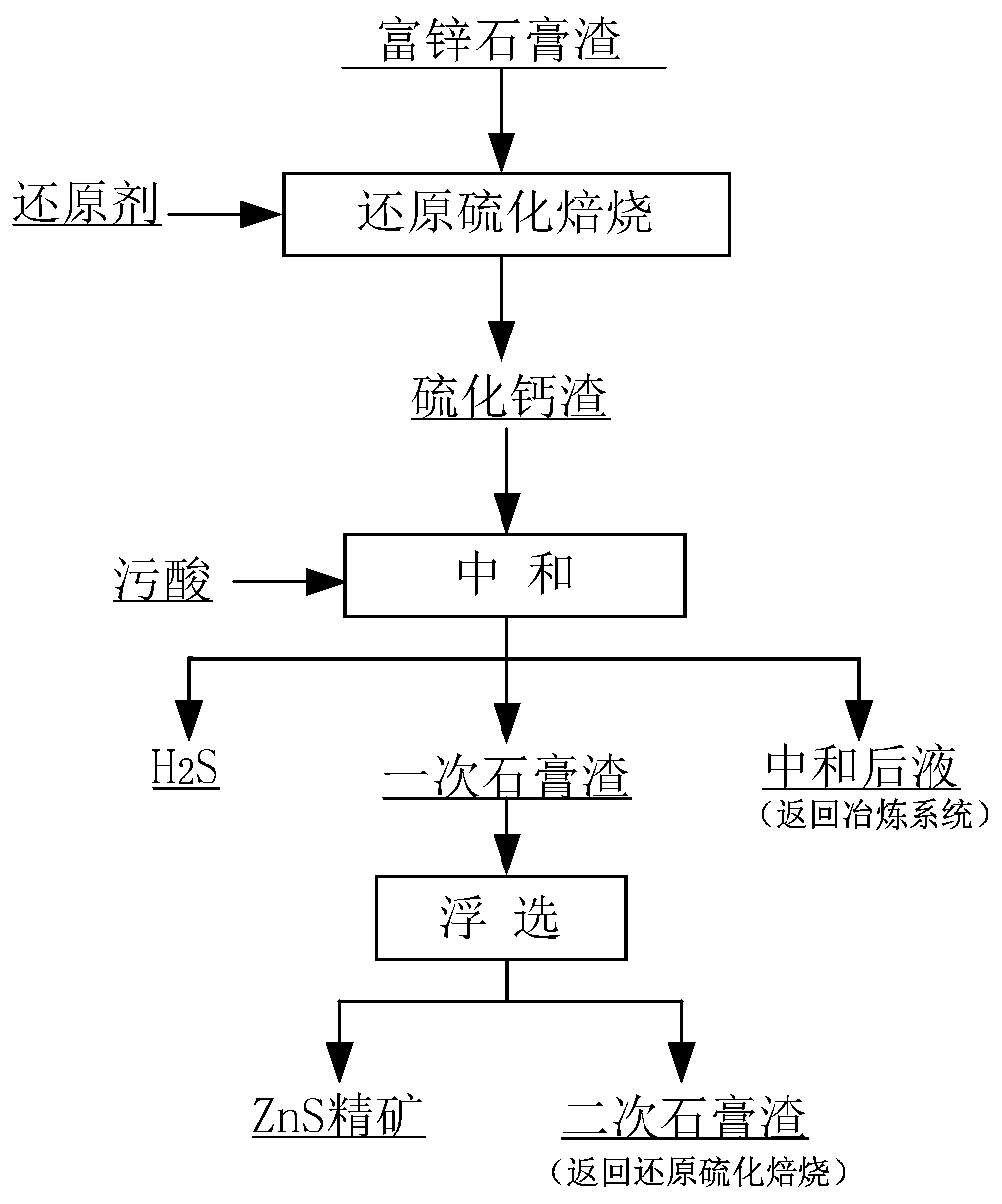

Method for comprehensively recycling zinc-rich gypsum slag resources

A gypsum slag and zinc-enriched technology, which is applied to the improvement of process efficiency, magnesium/calcium/strontium/barium sulfide/polysulfide, flotation, etc., can solve the problem of inability to realize valuable metal recovery and zinc sulfide flotation recovery Poor effect, high equipment investment and operating costs, etc., to achieve the effect that is conducive to industrial production, mild process conditions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The zinc-containing gypsum slag used in this example comes from a large-scale zinc smelter in Zhuzhou, and its specific components are shown in Table 1. The main components of the neutralized slag are dihydrate, calcium sulfate and zinc hydroxide, and the content of calcium sulfate dihydrate is 65.6%. The zinc hydroxide content is 18.3%.

[0047] Main chemical composition / % of the slag in Table 1

[0048]

[0049] The zinc smelting sewage acid used in this example comes from a zinc-zinc smelting plant in Hengyang, Hunan, and its specific composition is shown in Table 2.

[0050] Table 2 Main Components of Zinc Smelting Sewage Acid / (mg / L)

[0051]

[0052] A method for comprehensive recovery of zinc-rich gypsum slag resources, the specific steps are as follows:

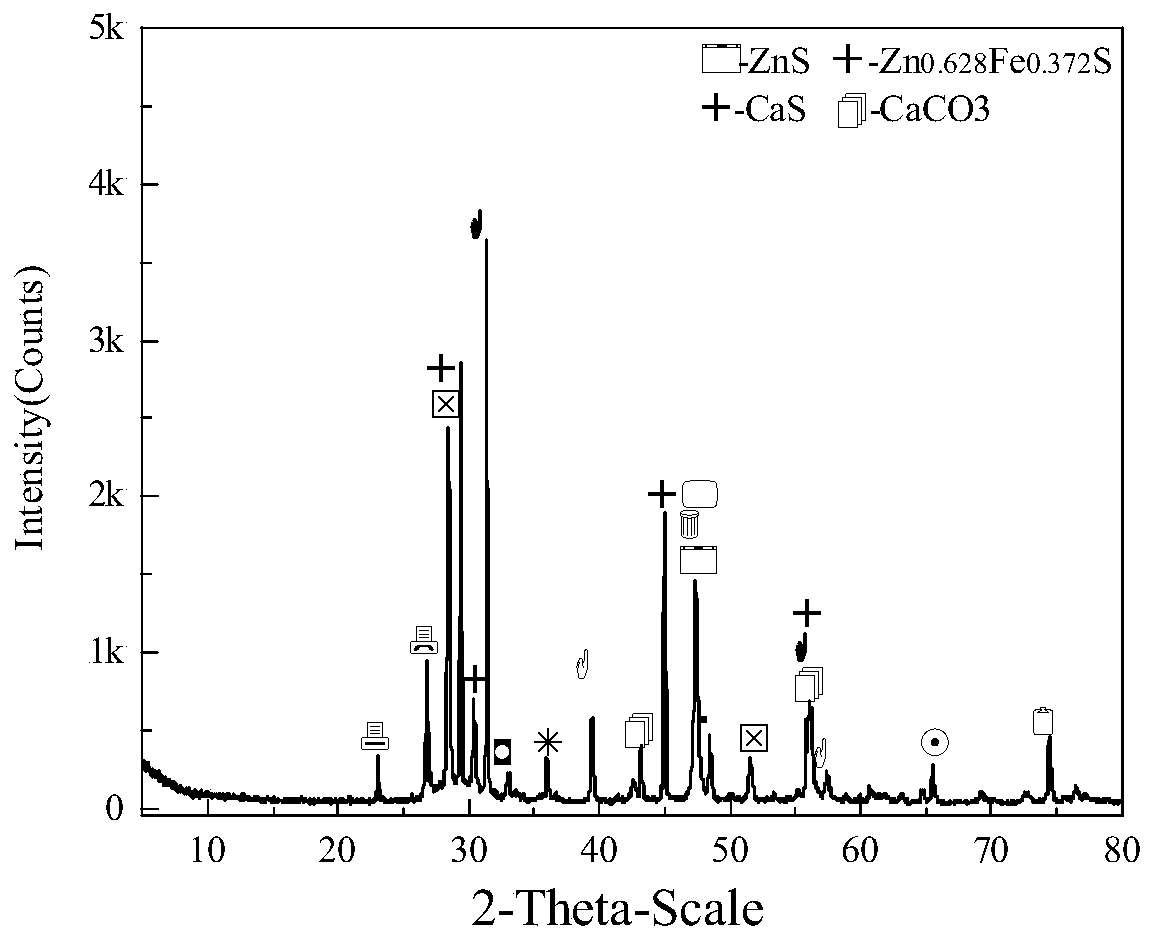

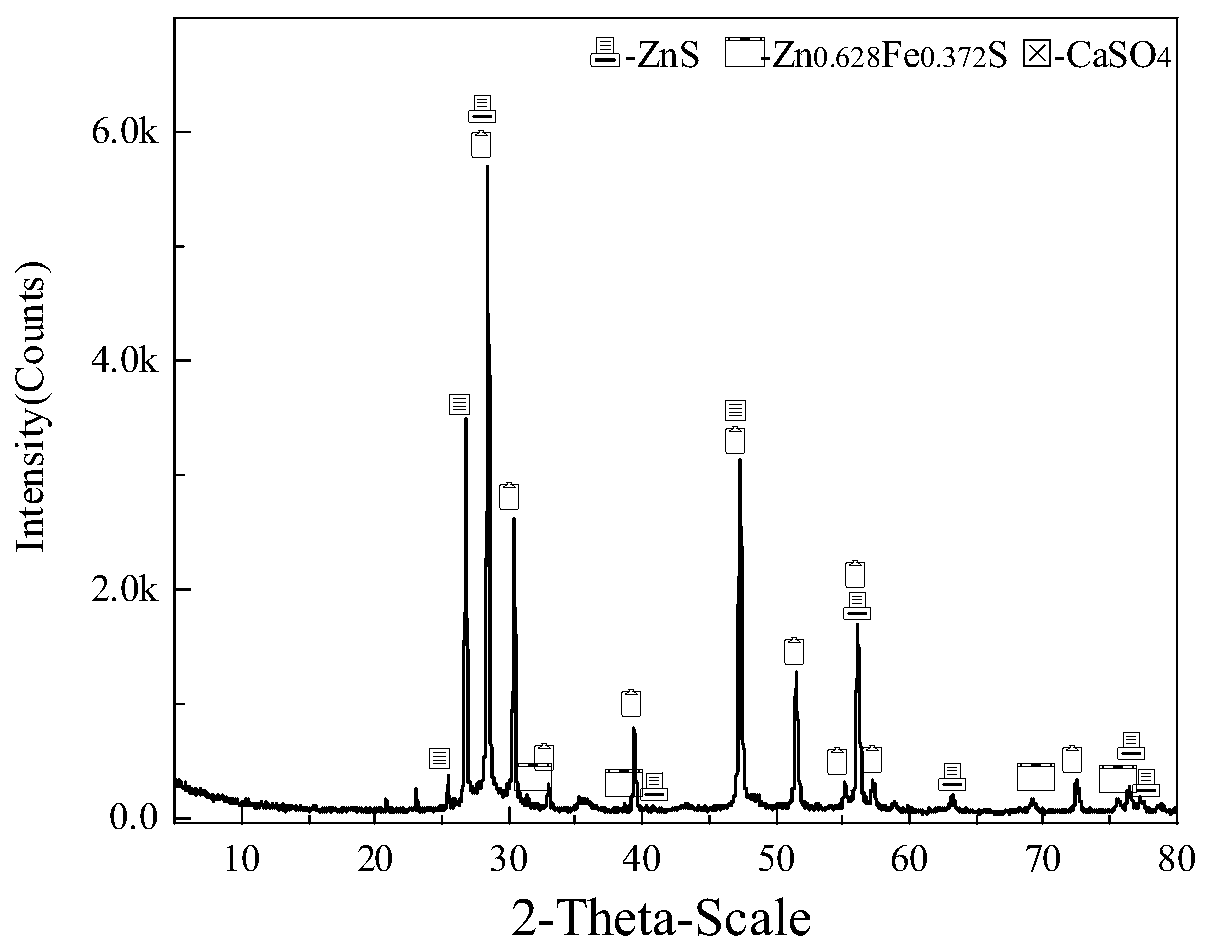

[0053] (1) Take 3000kg of the above-mentioned naturally air-dried gypsum slag and 450kg of coke powder with a particle size of 80% less than 1mm and mix them evenly. The feed rate of the machine and the...

Embodiment 2

[0067] The zinc-containing gypsum slag used in this example comes from a large-scale zinc smelter in Qujing, Yunnan, and its specific composition is shown in Table 3. The main components of the neutralized slag are dihydrate, calcium sulfate and zinc hydroxide, and the content of calcium sulfate dihydrate is 87.5%. , the content of zinc hydroxide is 8.63%.

[0068] Main chemical composition / % of the slag in table 3

[0069]

[0070] The zinc smelting sewage acid used in this example comes from a zinc-zinc smelting plant in Chenzhou, Hunan, and its specific composition is shown in Table 4.

[0071] Table 4 Main Components of Zinc Smelting Sewage Acid / (mg / L)

[0072]

[0073] A method for comprehensive recovery of zinc-rich gypsum slag resources, the specific steps are as follows:

[0074] (1) get above-mentioned naturally air-dried gypsum slag 3000kg and 300kg particle size and be that 80% are less than 1mm wood charcoal powder mixing, the material after above-mentioned...

Embodiment 3

[0088] The zinc-containing gypsum slag used in this example comes from a large-scale zinc smelter in Zhuzhou, and its specific components are shown in Table 1.

[0089] The zinc smelting sewage acid used comes from a zinc-zinc smelter in Hengyang, Hunan, and its specific composition is shown in Table 2.

[0090] A method for comprehensive recovery of zinc-rich gypsum slag resources, the specific steps are as follows:

[0091] (1) Take 3000kg of the above-mentioned naturally air-dried gypsum slag and 600kg of coke powder with a particle size of 80% less than 1mm and mix them evenly. The feed rate of the machine and the belt speed of the steel belt furnace ensure that the thickness of the material layer is 10-20cm. Nitrogen is introduced to control the running speed of the steel belt and the furnace temperature so that the material is heated at a constant temperature of 850°C for 60 minutes, and the roasted sample is cooled to Take it out after room temperature; through chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com