Vinyl fluorine-containing copolymer, waterproof and oil-proof composition containing vinyl fluorine-containing copolymer, and application thereof

A vinyl-based, water- and oil-repellent technology, applied in non-fiber pulp addition, retention aid addition, papermaking, etc., can solve the problems of inability to prevent oil, poor waterproof and oil-repellent performance, and heat-resistant oil, and achieve stable performance, reduce product cost, and improve waterproof and oil-proof effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

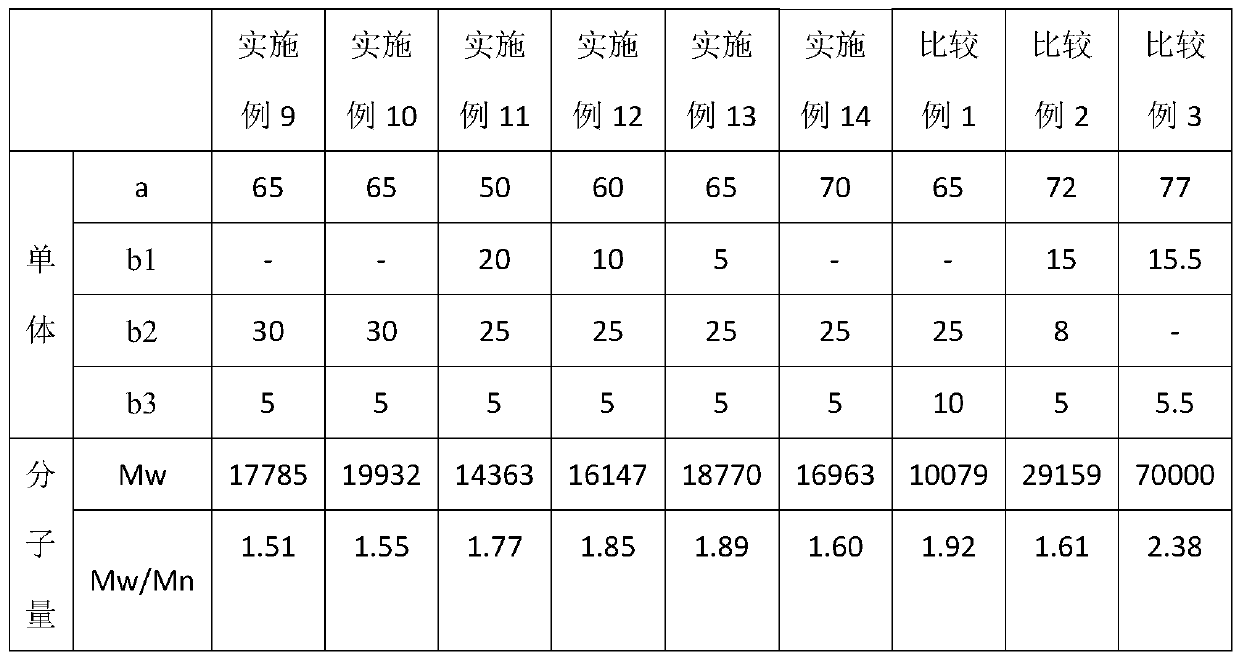

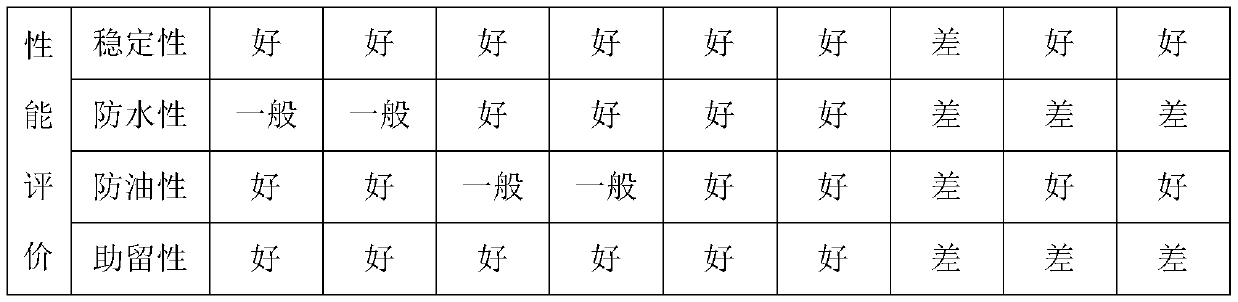

Examples

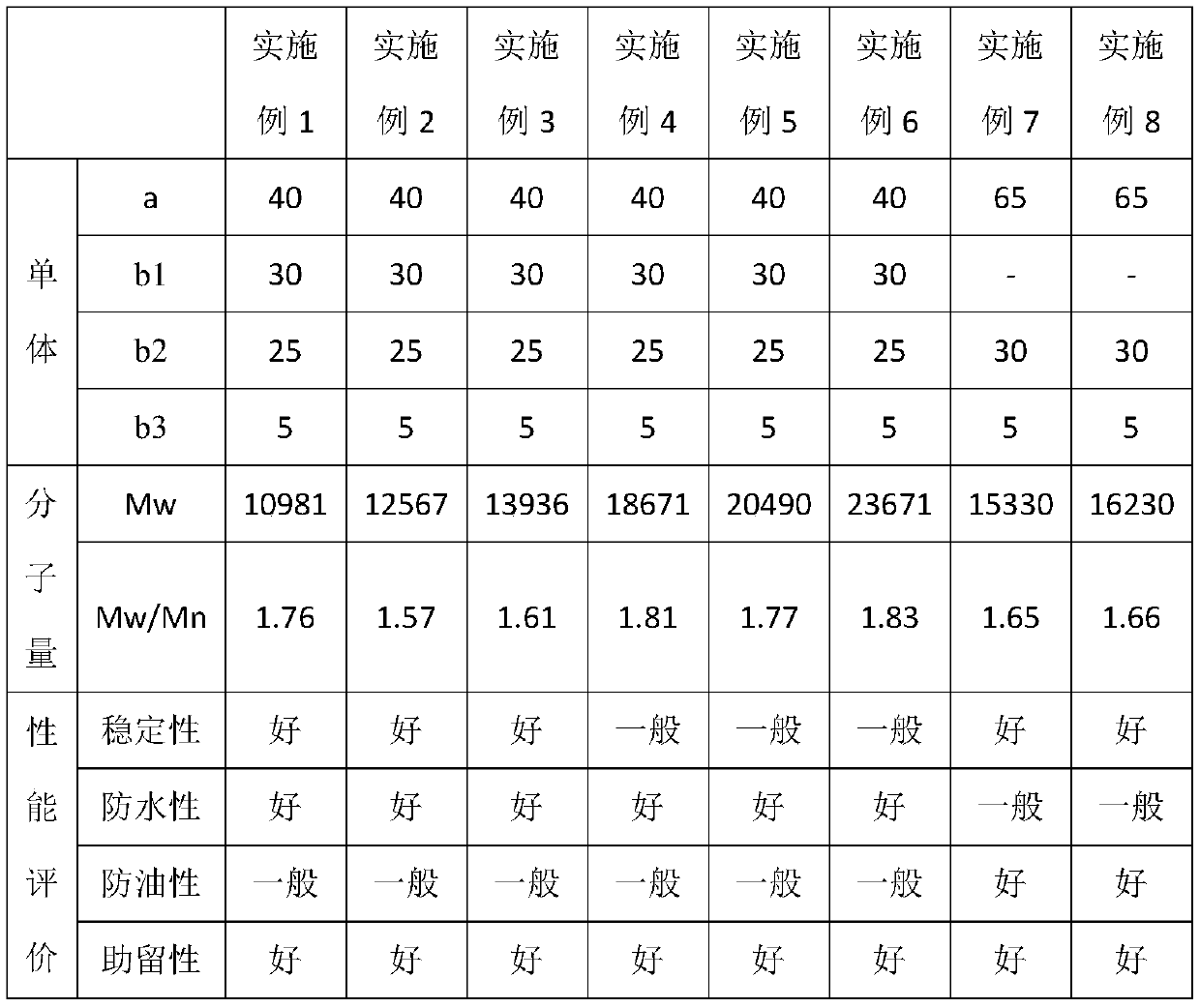

Embodiment 1

[0069] Add 250 parts of propylene glycol methyl ether as a solvent in a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a condenser tube, turn on the stirrer, and add 40 parts of CH 2 =CH-C(=O)-O-CH 2 CH 2 -F(CF 2 ) 6 , 30 parts of methyl methacrylate, 25 parts of dimethylaminoethyl methacrylate and 5 parts of acrylic acid and 1 part of 2,2'-azobisisobutyronitrile, 0.5 parts of dodecyl mercaptan Mix evenly, add to a four-neck flask under nitrogen atmosphere, react at 60°C for 10 hours, complete polymerization, cool to room temperature to obtain a vinyl-based fluorine-containing copolymer solution, and prepare it into a water-soluble solution with 1% HCl solution ammonium salt, and finally diluted with deionized water to form a water-dispersed water- and oil-repellent composition with a solid concentration of 20%.

Embodiment 2

[0071] Add 250 parts of propylene glycol methyl ether as a solvent in a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a condenser tube, turn on the stirrer, and add 40 parts of CH 2 =CH-C(=O)-O-CH 2 CH 2 -F(CF 2 ) 6 , 30 parts of ethyl acrylate, 25 parts of dimethylaminoethyl methacrylate and 5 parts of acrylic acid are mixed with 1 part of 2,2'-azobisisobutyronitrile and 0.5 parts of dodecyl mercaptan , added to a four-necked flask under a nitrogen atmosphere, reacted at 60°C for 10 hours, completed the polymerization, cooled to room temperature, and obtained a vinyl-based fluorine-containing copolymer solution, which was formulated into a water-soluble ammonium with 1% HCl solution salt, and finally diluted with deionized water to form a water-dispersed water- and oil-repellent composition with a solid concentration of 20%.

Embodiment 3

[0073] Add 250 parts of propylene glycol methyl ether as a solvent in a four-necked flask equipped with an electric stirrer, a constant pressure dropping funnel, a thermometer and a condenser tube, turn on the stirrer, and add 40 parts of CH 2 =CH-C(=O)-O-CH 2 CH 2 -F(CF 2 ) 6, 30 parts of isobutyl methacrylate, 25 parts of dimethylaminoethyl methacrylate and 5 parts of acrylic acid and 1 part of 2,2'-azobisisobutyronitrile, 0.5 parts of dodecyl sulfide Mix the alcohol evenly, add it into a four-necked flask under nitrogen atmosphere, react at 60°C for 10 hours, complete the polymerization, cool to room temperature, and obtain a vinyl-based fluorine-containing copolymer solution, which is formulated with 1% HCl solution into The water-soluble ammonium salt is finally diluted with deionized water to form a water-dispersed water- and oil-repellent composition with a solid concentration of 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com