A kind of lithiated silicon-based composite material and its preparation method and application

A technology of silicon-based composite materials and lithiation, applied in chemical instruments and methods, silicon compounds, silicates, etc., can solve the problems of low Coulombic efficiency, low conductivity of silicon-based oxide materials, lithium loss, etc., and achieve Coulombic High efficiency, reduce irreversible lithium loss, and compensate for consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

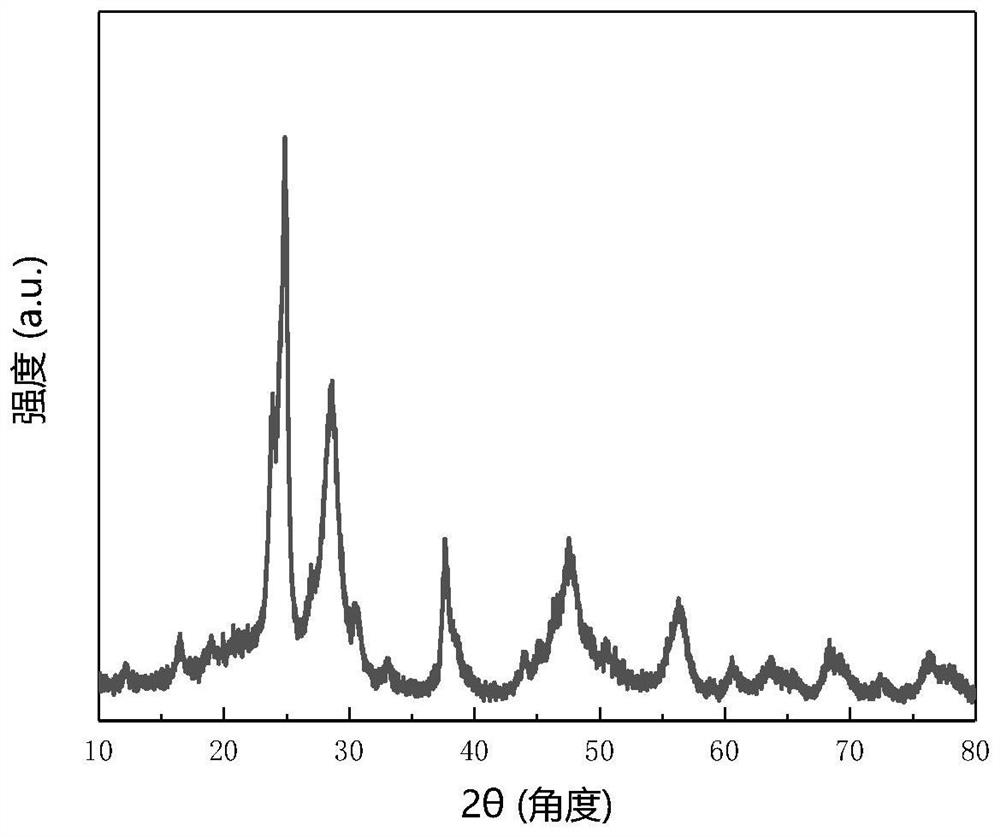

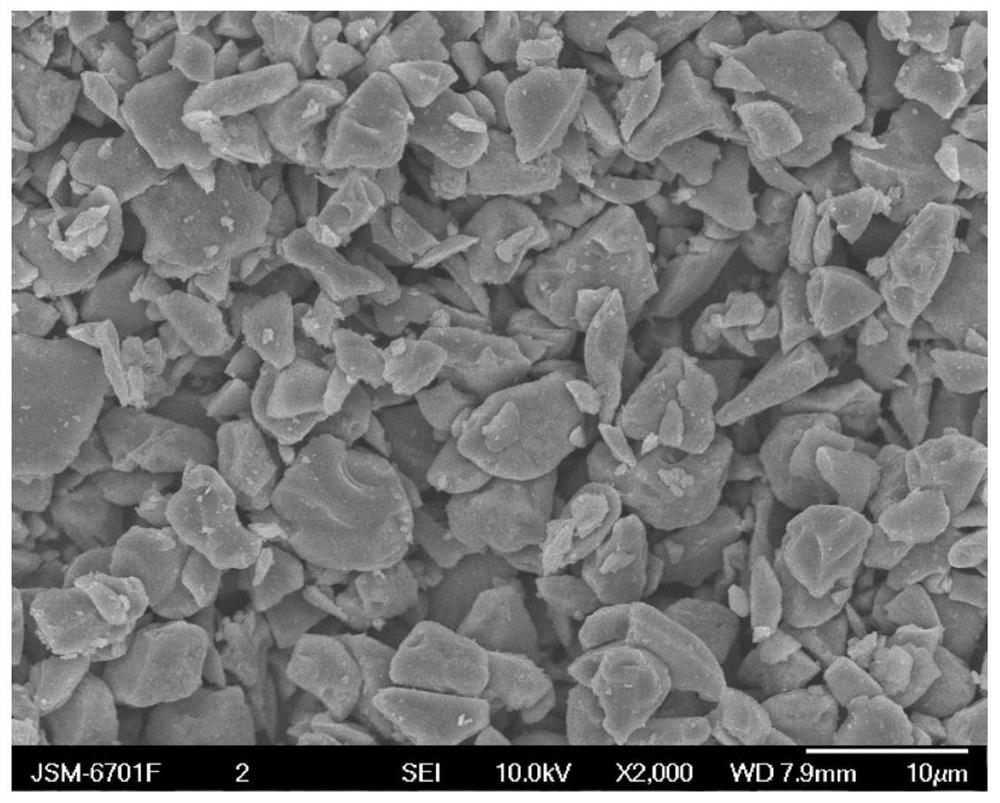

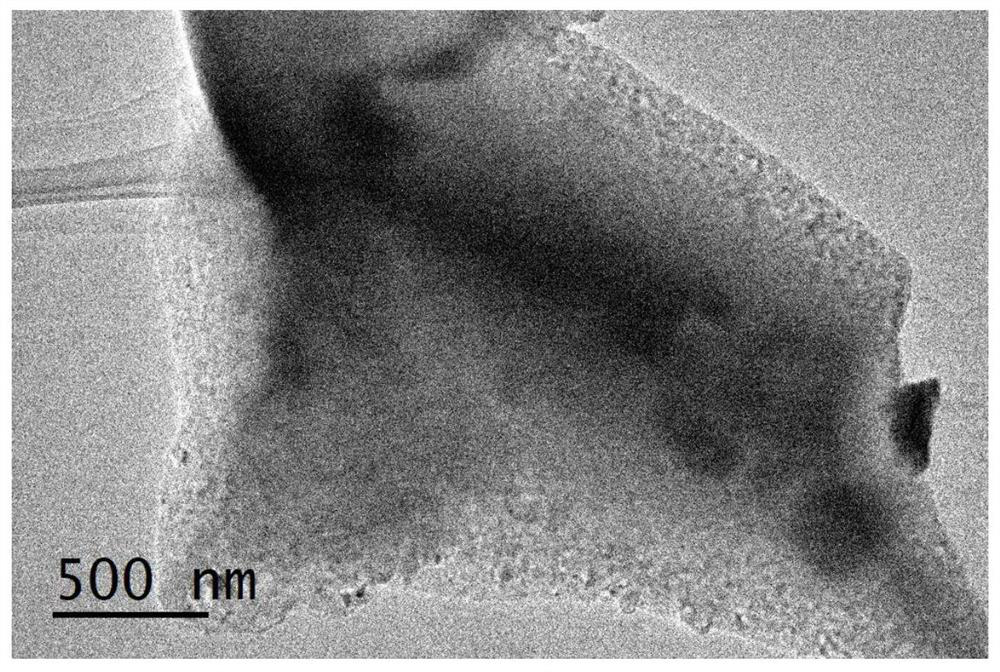

[0050] (1) Carbon-coated silicon-based oxide powder: the silicon-based oxide powder used in the present invention is a commercial silicon oxide material, i.e. SiO x , where x=1. The silicon oxide material is crushed by air flow to particles with a particle size of 1-10 μm, placed in a CVD vapor deposition furnace, and after thermal decomposition and deposition of acetylene gas at 750 ° C for 3 hours, the material is maintained in an atmosphere of inert gas protection. The temperature was raised to 900° C. at a heating rate of 5° C. / min and kept for 1 hour to obtain a silicon oxide material uniformly coated with a carbon layer.

[0051] (2) Dissolving process: dissolve biphenyl in an ultra-dry tetrahydrofuran solvent and stir to dissolve, add 350 mg of lithium flakes into a 50 mL solution under an inert atmosphere and stir magnetically for 30 minutes to obtain a homogeneous solution containing lithium and biphenyl complexes. phase solution, the concentration of aryl lithium wa...

Embodiment 2

[0059] In the dissolving process, the ether solvent was changed to 1,3-dioxolane as the solvent system, and the rest was the same as in Example 1 to prepare the negative electrode active material.

Embodiment 3

[0061] In the dissolving process, the ether solvent was changed to ethylene glycol dimethyl ether as the solvent system, and the rest was the same as in Example 1 to prepare the negative electrode active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com