System for treating dust-containing tail gas

A technology for exhaust gas and dust, which is applied in the field of systems for processing dust-containing exhaust gas, can solve the problems of long time to determine the position of broken bags, high risk, difficult to filter, etc., to avoid poor sealing and prolong the operation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

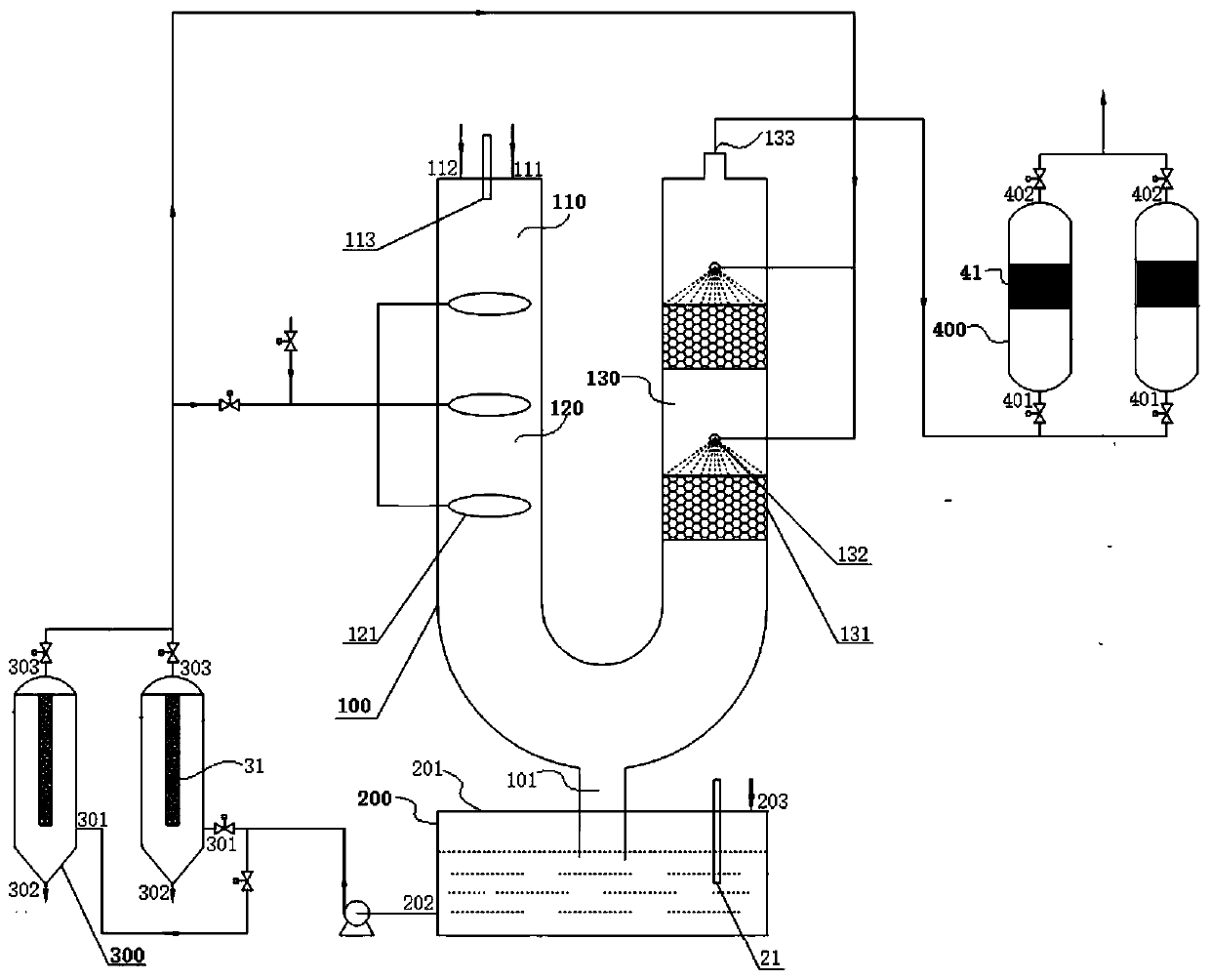

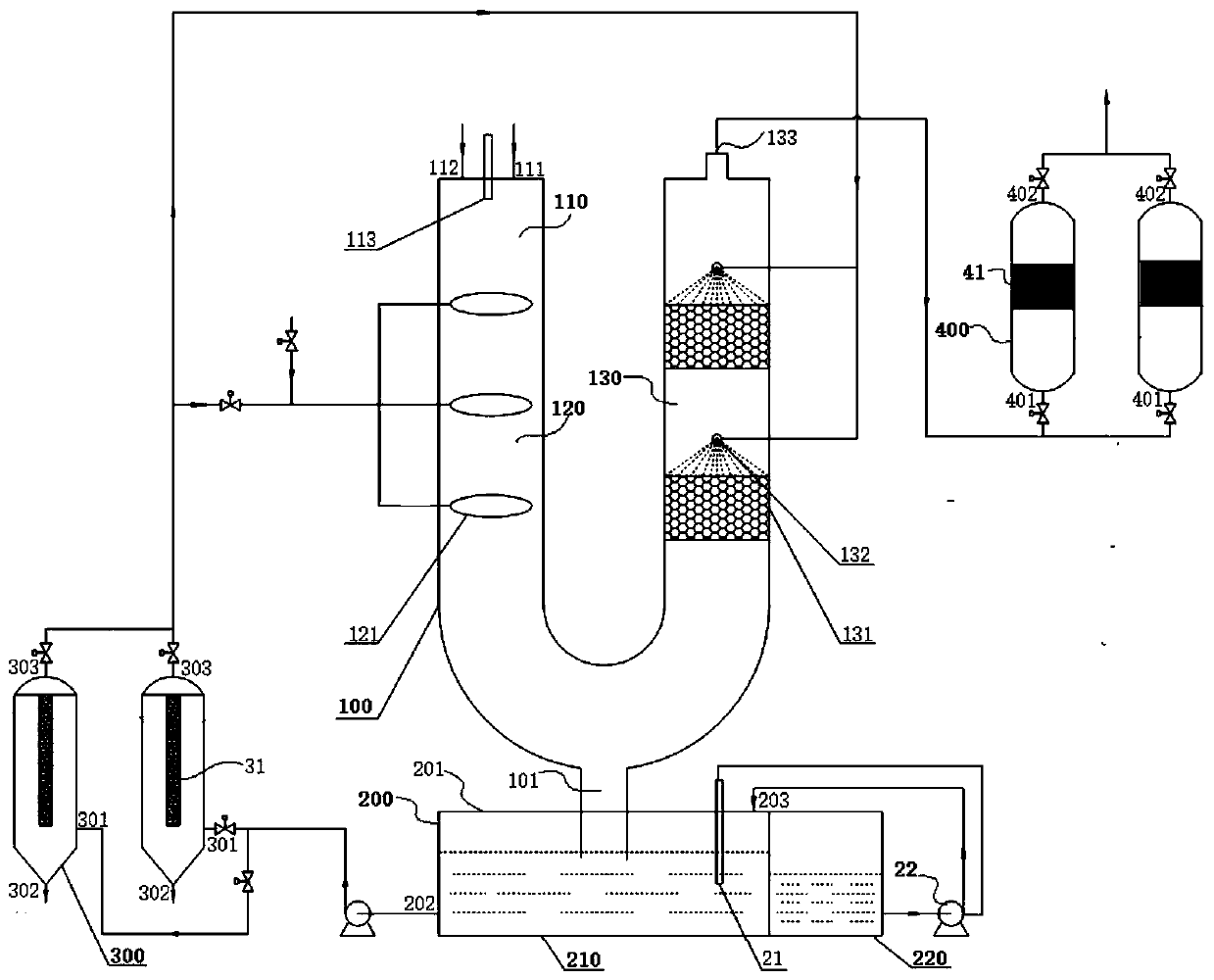

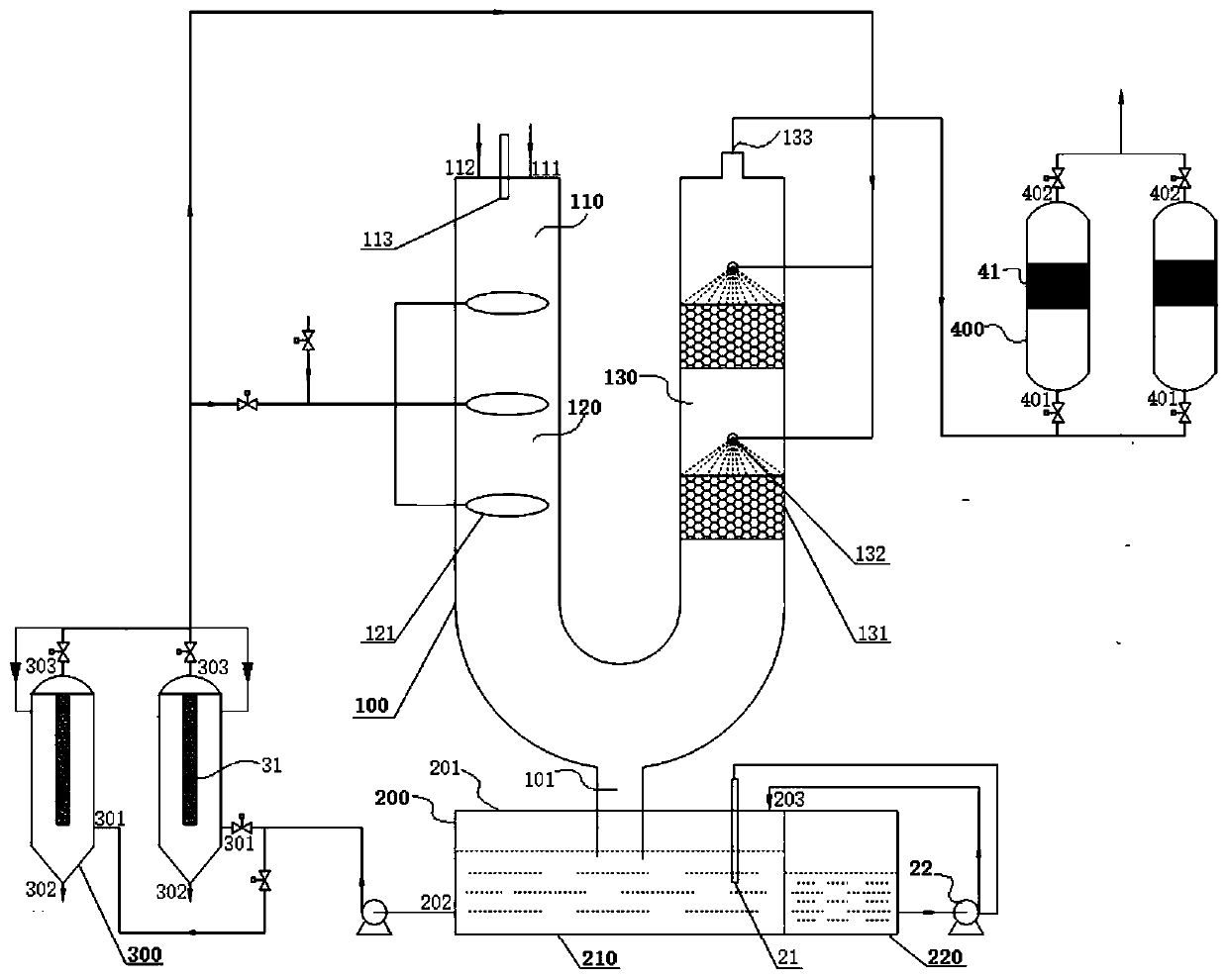

[0084] A system for treating dusty exhaust gases such as Figure 7 As shown, the dusty tail gas contains trichlorosilane, dichlorodihydrosilane, silane, disilane, ethyl orthosilicate, octamethylcyclotetrasiloxane, polysilazane, tetramethylsilane, three Silicon-containing tail gas such as methyl silane, the system includes:

[0085] Combustion-dust removal-dust collection device 100 includes:

[0086] Combustion section 110, combustion section 110 has dusty tail gas inlet 111, assisted gas inlet 112 and heat source electric heating rod 113, the operating temperature of the electric heating rod is 800°C, the material of the inner wall of the combustion section is high temperature resistant material, and the outer wall of the combustion section is equipped with Heat exchange jacket, the heat exchange medium is water, so that the temperature of the outer wall of the combustion section does not exceed 60°C;

[0087] Dust removal section 120, the dust removal section 120 is connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com