Liquid fertilizer treatment process for livestock manure

A treatment process and biochemical treatment technology, applied in animal husbandry wastewater treatment, oxidized water/sewage treatment, liquid fertilizer and other directions, can solve the problems of long treatment time and cumbersome treatment steps, so as to reduce treatment costs, simplify the process and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

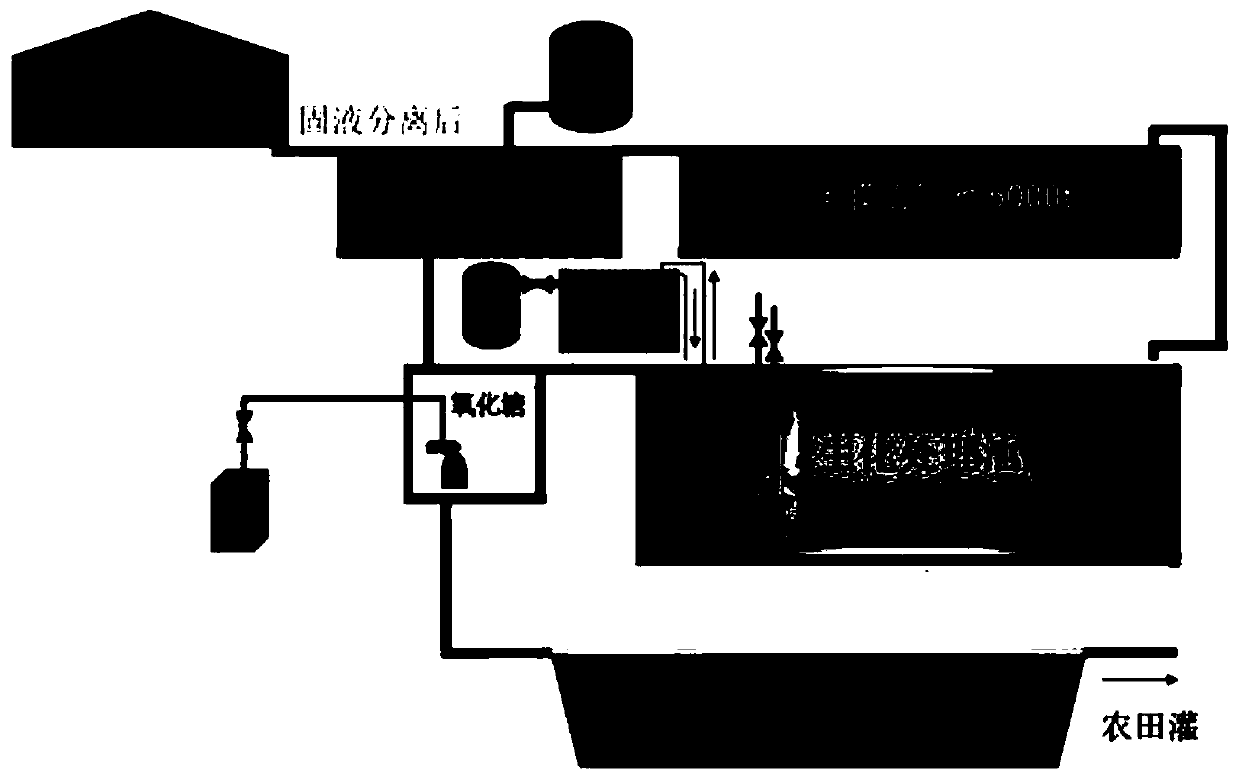

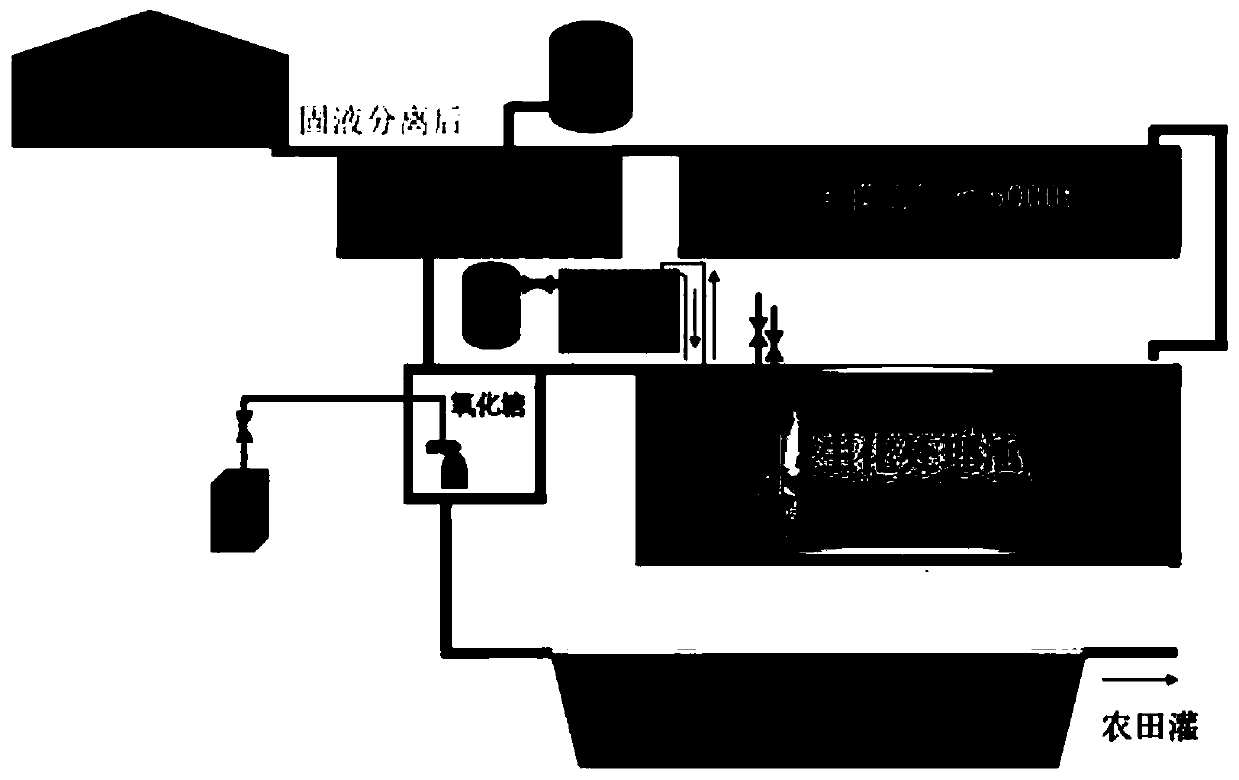

[0040] The processing object of this embodiment is pig manure produced by a large pig farm in Tingfeng, Yongzhou, Hunan Province, and the process roadmap is as follows figure 1 As shown, in the process, an aerobic microorganism cultivation pond connected with the aerobic biochemical treatment pond is set, and the volume of the aerobic microorganism cultivation pond is 100 cubic meters, and the number of QS1 aerobic bacteria initially cultivated in the aerobic microorganism cultivation pond is greater than 10 7 , the method includes the following steps:

[0041] a) Carry out solid-liquid separation of pig feces and urine, import the liquid separation into the raw water tank, add facultative anaerobic bacteria-Enterococcus faecium EC-11 bacterial powder in the raw water tank, and the bacterial strain of described Enterococcus faecium EC-11 is Enterococcus faecium, the strain is preserved in the General Microbiology Center of China Committee for the Collection of Microbial Strai...

Embodiment 2

[0068] The processing object of the present embodiment and the bacterial strain used are identical with embodiment 1, and described technique comprises the following steps:

[0069] a) Carry out solid-liquid separation of pig manure and urine, import the liquid separation into the raw water tank, add facultative anaerobic bacteria-Enterococcus faecium EC-11 bacterial powder into the raw water tank,

[0070] b) The effluent of the raw water pool flows into the black film biogas digester for anaerobic fermentation treatment, and the treated sewage enters the aerobic biochemical treatment tank for treatment; the addition of Enterococcus faecium EC-11 bacterial powder in the step a) is not less than 1.5 grams per cubic meter, calculated when the number of live bacteria of Enterococcus faecium EC-11 in the raw water pool is not less than 750,000 cfu / g.

[0071] c) Arrange aerobic microorganism culture pool, and add Bacillus subtilis QS1 bacterium powder in the culture pond, the add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com