Kasugamycin raw powder, and preparation method and application thereof

A technology for kasugamycin and raw powder, applied in the field of kasugamycin raw powder and its preparation, can solve the problems of unstable physicochemical properties and use effect of products, affecting the popularization and use of kasugamycin, crop, human or animal injury and the like , to reduce the number of miscellaneous algae, improve the control effect, and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of kasugamycin former powder of the present invention comprises the following steps:

[0035] (1) Pick Streptomyces aureus strains and inoculate them in the shake flask seed fermentation medium, and cultivate them for 24 to 36 hours at 27 to 29° C. at a rotating speed of 180 to 200 rpm to obtain a bacterial concentration of 10 7 ~10 8 CFU / mL shake flask seed liquid, including 1.5% soybean cake powder and 0.5% yeast powder in the shake flask seed fermentation medium.

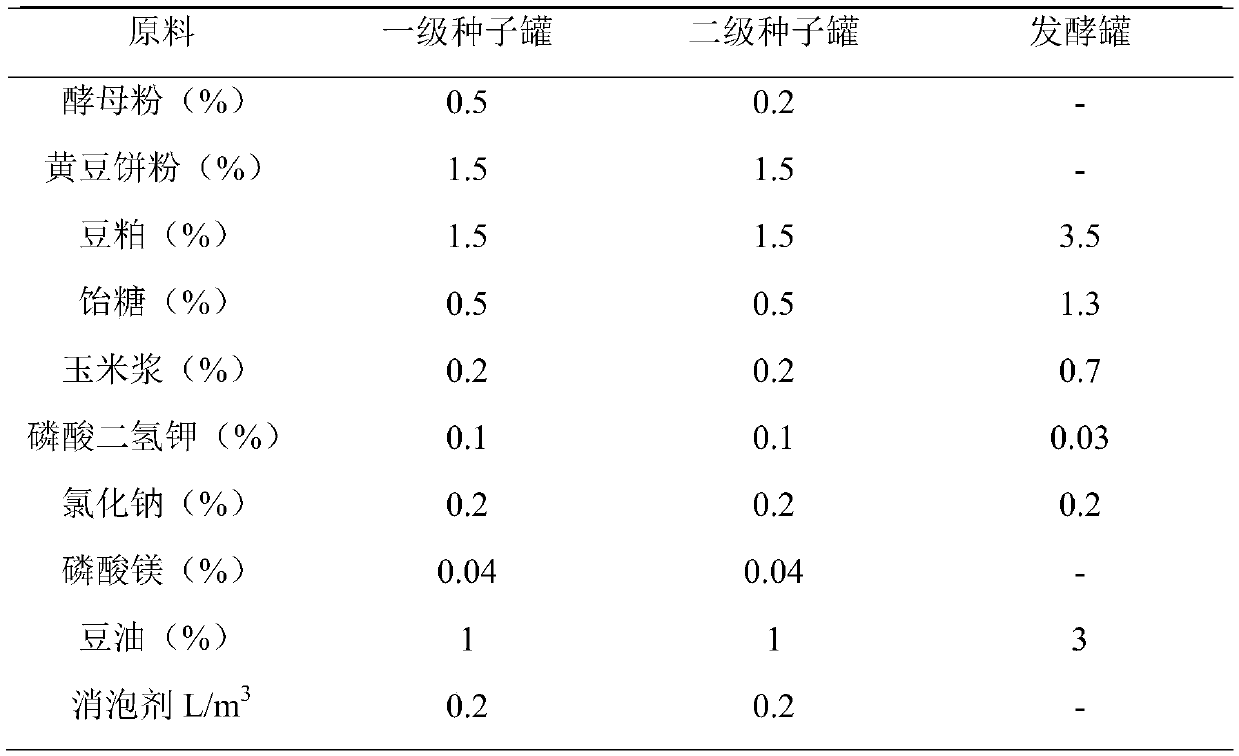

[0036] (2) Inoculate the shake flask seed liquid into the fermentation medium of the primary seed tank according to the volume ratio of 8 to 10%, at 27 to 29°C, at a speed of 80 to 100rpm, and with an air volume of 18 to 20m 3 24~30h of fermenting and cultivating under / h, obtains primary seed liquid, comprises 0.5% yeast powder, 1.5% soybean cake powder or soybean meal, 1% soybean oil and 0.2L / m 3 defoamer.

[0037] (3) Inoculate the primary seed liquid into the secondary seed ta...

Embodiment 2

[0043] Before preparing kasugamycin, various culture media and seed tanks were sterilized at 121-123° C. for 35-40 minutes.

[0044] In this example, Streptomyces aureus was purchased from Biological Company.

[0045] The concrete preparation method of described kasugamycin former powder is as follows:

[0046] 1. Shake flask seed solution preparation

[0047]Pick Streptomyces microaureus from the inclined surface of the test tube and inoculate it in the seed fermentation medium of the shake flask, and cultivate it at 28°C and 180rpm for 24-36h, and the concentration of the prepared bacteria is 10 7 ~10 8 CFU / mL shake flask seed solution, wherein the formula of shake flask seed fermentation medium is: yeast powder 0.5%, soybean cake powder 1.5%, maltose 0.5%, corn steep liquor 0.2%, potassium dihydrogen phosphate 0.1%, sodium chloride 0.2 %, magnesium phosphate 0.04%, soybean oil 1%.

[0048] 2. Preparation of seed liquid in primary seed tank

[0049] Take the shake flask...

Embodiment 3

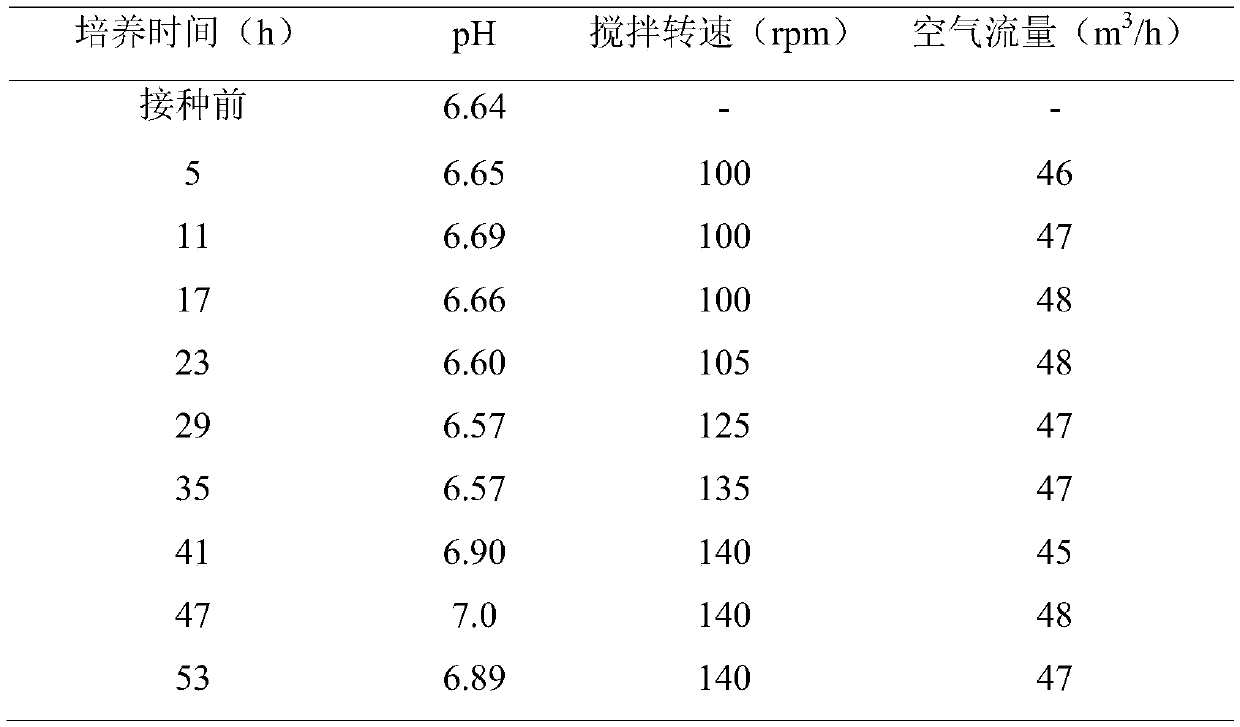

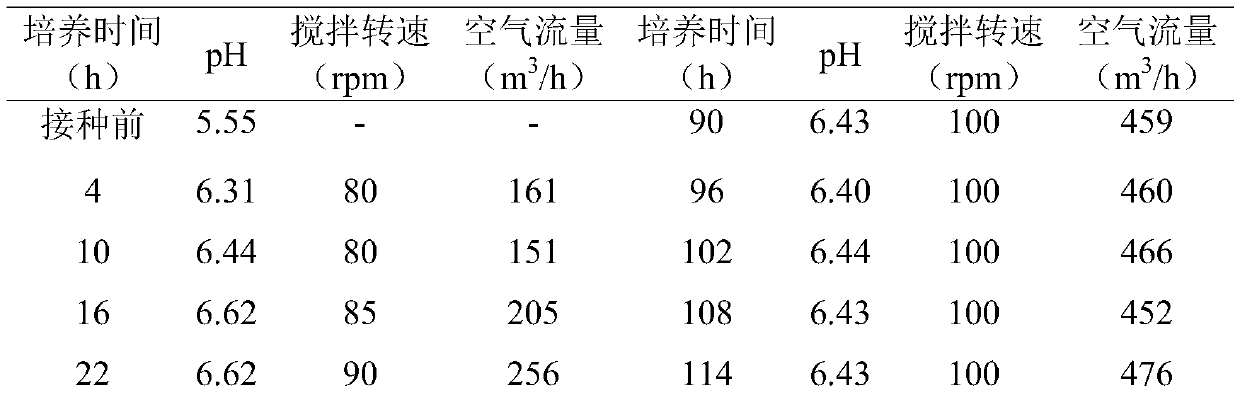

[0061] 1. During the fermentation process of Streptomyces aureus, check and record the pH, stirring speed and air flow in the seed tank and fermenter every 6 to 12 hours. The results are shown in Table 2 and Table 3. The results show that: in the fermentation process, by gradually increasing the stirring speed and air flow, the oxygen required by Streptomyces aureus can be effectively maintained, and the stability of the pH of the fermented liquid can be well controlled by supplementing ammonia, effectively ensuring the production of kasugamycin. Quality and potency.

[0062] Table 2 The determination of each index in the seed tank fermentation process

[0063]

[0064] Table 3 The determination of each index in the fermenter fermentation process

[0065]

[0066]

[0067] 2. During the fermentation process of Streptomyces aureus strains, test the bacterial concentration, reducing sugar / total sugar content in the seed tank and fermenter every 6 hours; measure the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com