Preparation of three-dimensional SiO2-Ag porous structure and application of three-dimensional SiO2-Ag porous structure in detection of volatile organic compounds

A volatile organic compound, porous structure technology, applied in measurement devices, material excitation analysis, instruments, etc., can solve the problems of easy disintegration, troublesome preparation of MOFs structure, difficult use and storage of substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] Preparation of atmospheres with different concentrations: According to Raoult's law, the partial pressure of the components in the ideal mixture is related to the mole fraction of the components in the solution. In this experiment, n-decane with a small vapor pressure is used as an irrelevant component to prepare the mixture Liquid, by calculating the vapor pressure of the target gas in the mixture with n-decane as solvent, and then calculate its gas concentration. By changing the molar ratio of n-decane / pure target gas solution, different concentrations of target gas atmospheres can be obtained.

[0068] Raman measurement of VOCs vapor: Before Raman measurement, first cut the aged substrate into a 4mm×4mm solid as the Raman active matrix. Add 2ml of the prepared mixed solution to the liquid pool in the closed Raman cell. After the target gas volatilizes and reaches saturation, quickly put the cut substrate into the closed Raman cell, and take it out after a period of a...

Embodiment 1

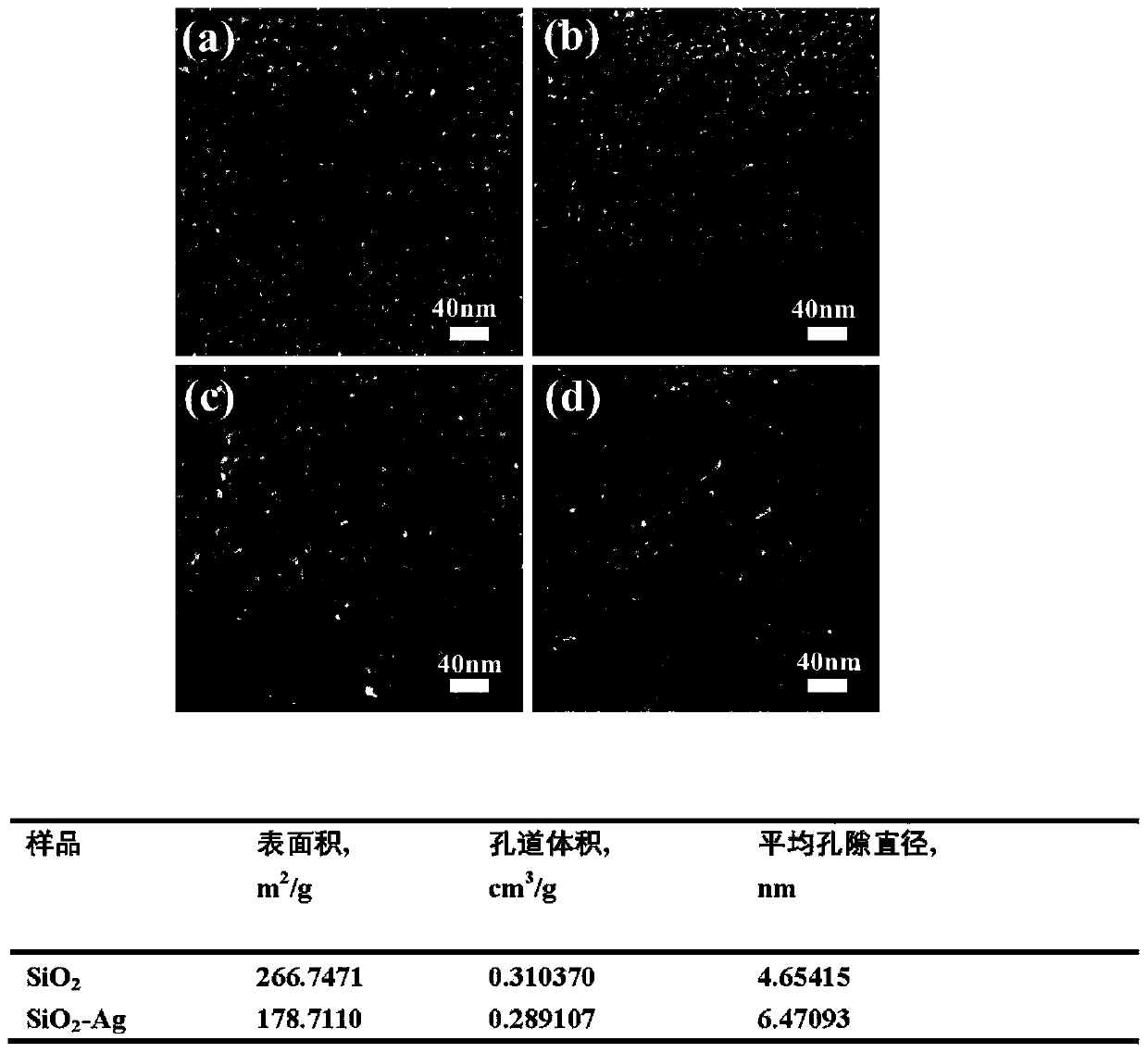

[0070] 1. Synthesis of silica sol

[0071] The method for preparing silica sol is sol-gel method. Silica microspheres with a diameter of about 10 nm were prepared by hydrolyzing tetraethyl silicate by an acid-catalyzed method. First mix tetraethyl orthosilicate, absolute ethanol and water with a volume ratio of 2.2:1.655:0.25 evenly, then add 0.118ml of hydrochloric acid solution with a concentration of 0.036M during the stirring process, and stir thoroughly for 60 minutes to obtain a colorless and transparent The oily liquid is silica sol.

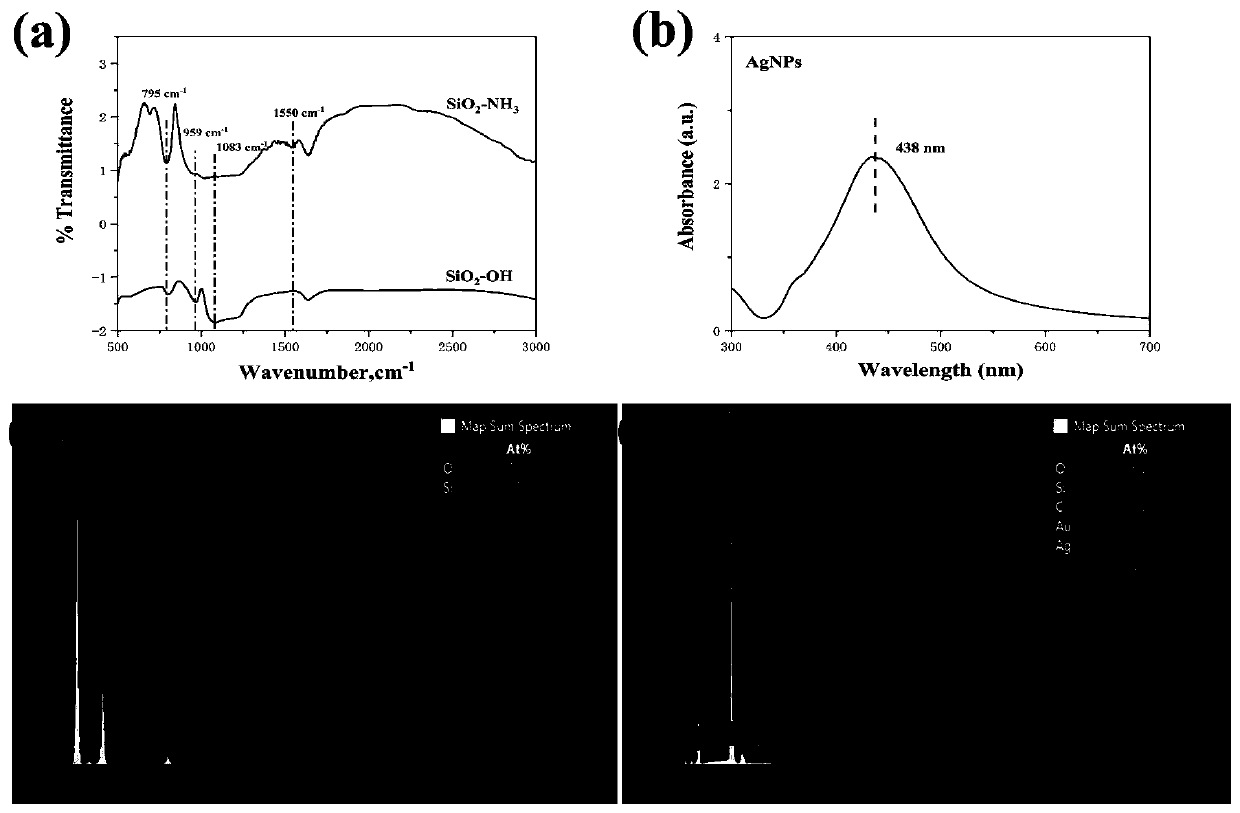

[0072] 2. Preparation of Ag-NPs

[0073] First prepare silver ammonia solution, dissolve silver nitrate in deionized water under vigorous stirring, then add ammonia solution dropwise to it to make 0.1M silver ammonia solution; mix 0.017g sodium citrate, 0.2175g PVP and 0.055g glucose Dissolve in 50mL deionized water, stir and heat to 100°C, add 4.5mL silver ammonia solution dropwise within 2min, keep the mixed solution at 100°C for 30 ...

Embodiment 2

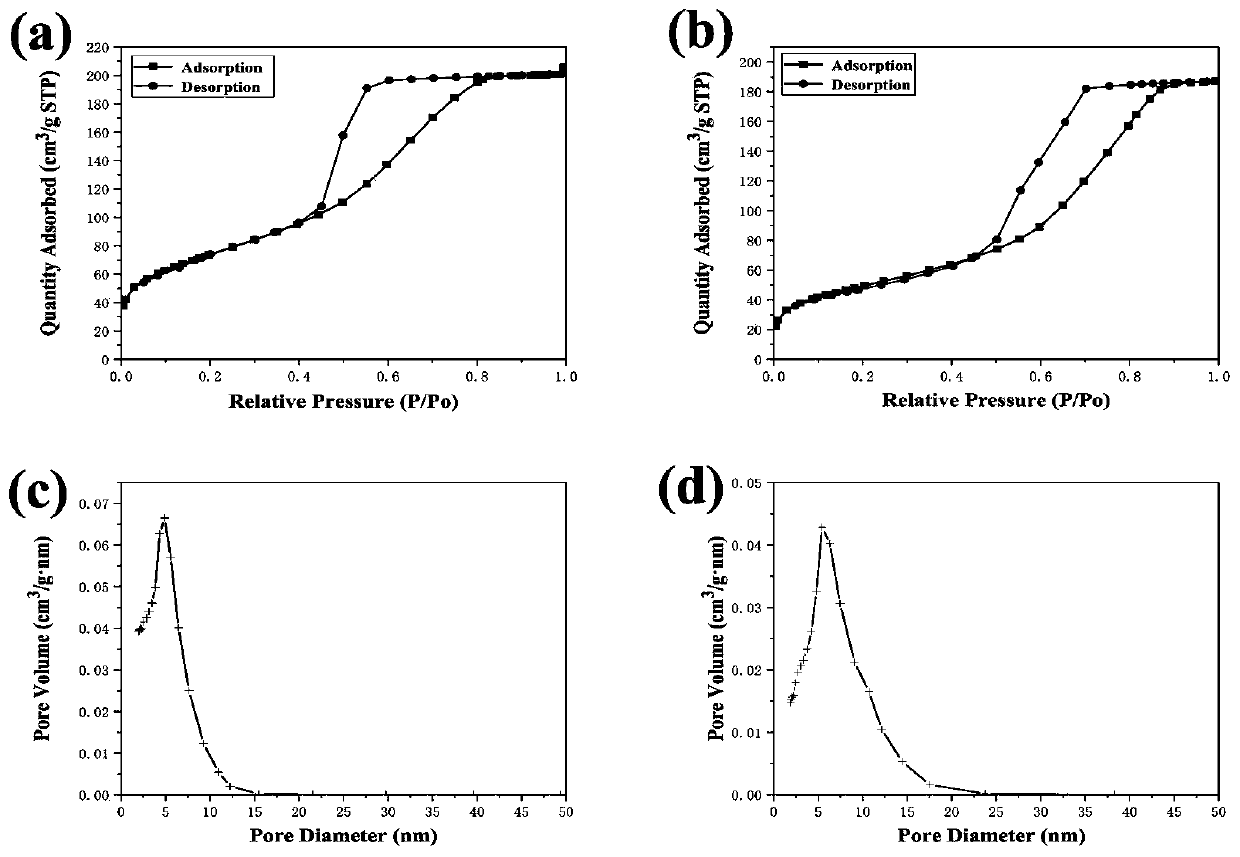

[0077] by adding to SiO 2 Different volumes of AgNPs solutions were added to the sol to adjust the SiO 2 -The content of silver nanoparticles in the Ag sol, so as to obtain SiO with different doping amounts 2 -Ag three-dimensional porous structure matrix. The detection results showed that the addition of 70 μL AgNPs solution of SiO 2 -Ag substrate has the best SERS enhancement effect ( Figure 7 a), is SiO 2 3.6 times the base ( Figure 6 ). When gas molecules are in contact with or close to silver nanoparticles, the electromagnetic enhancement mechanism (EM) and chemical enhancement mechanism (CE) of silver nanoparticles will increase the intensity of the incident field and the intensity of the scattered field, thus improving the detection sensitivity of gas molecules. The doping amount of silver nanoparticles will affect the response of the substrate to target gas molecules. When the doping amount is small, because the distance between the silver nanoparticles is too ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com