Carbonized fiber paperboard loaded Mo2C/NC catalyst as well as preparation method and application thereof

A technology of carbonized fiber and fiber paperboard, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high price, high cost, high catalytic activity, etc., and achieve good electrocatalytic hydrogen evolution performance, The effect of low production cost and wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

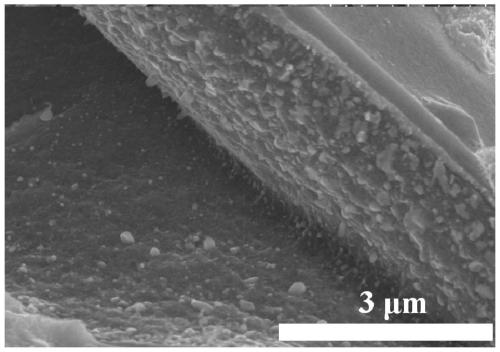

Image

Examples

Embodiment 1

[0028] Prepare the Mo of carbonized fiber cardboard load described in the present embodiment 2 The method of C / NC catalyst specifically comprises the following steps:

[0029] S1. Weigh and weigh 0.2g of ammonium molybdate tetrahydrate and 0.3g of dicyandiamide into a 50mL beaker, add 5mL of distilled water, and stir magnetically for 30min at room temperature to obtain an impregnation solution;

[0030] S2. At the same time, take a piece of 2cm*3cm*2mm fiber cardboard (mass is 0.589g), wash it repeatedly 5 times with absolute ethanol, and dry it at 60°C;

[0031] S3. Take out the dried fiber cardboard and place it in a watch glass, and evenly add the impregnation solution in S1 6 times;

[0032] S4. Then dry the fiber paperboard impregnated with the impregnation solution in an oven at 80°C for 15 minutes, then take it out and place it in a porcelain boat, put it into a tube furnace and calcinate it under the protection of high-purity argon for 3.5 hours, the calcining tempera...

Embodiment 2

[0034] Prepare the Mo of carbonized fiber cardboard load described in the present embodiment 2 The method of C / NC catalyst specifically comprises the following steps:

[0035] S1. Weigh and weigh 0.2g of ammonium molybdate and 0.4g of dicyandiamide into a 50mL beaker, add 5mL of distilled water, and stir magnetically for 30min at room temperature to obtain an impregnation solution;

[0036] S2. At the same time, take a piece of 2cm*3cm*2mm fiber cardboard (mass is 0.589g), wash it repeatedly 5 times with absolute ethanol, and dry it at 60°C;

[0037] S3. Take out the dried fiber cardboard and place it in a watch glass, and evenly add the impregnation solution in S1 6 times;

[0038] S4. Then dry the fiber paperboard impregnated with the impregnating solution in an oven at 80°C for 15 minutes, then take it out and put it in a porcelain boat, put it into a tube furnace and calcinate it under the protection of high-purity argon for 3.5 hours, the calcining temperature is 800°C, ...

Embodiment 3

[0040] Prepare the Mo of carbonized fiber cardboard load described in the present embodiment 2 The method of C / NC catalyst specifically comprises the following steps:

[0041]S1. Weigh and weigh 0.3g of ammonium molybdate and 0.3g of dicyandiamide into a 50mL beaker, add 5mL of distilled water, and stir magnetically for 30min at room temperature to obtain an impregnation solution;

[0042] S2. At the same time, take a piece of 2cm*3cm*2mm fiber cardboard (mass is 0.589g), wash it repeatedly 5 times with absolute ethanol, and dry it at 60°C;

[0043] S3. Take out the dried fiber cardboard and place it in a watch glass, and evenly add the impregnation solution in S1 6 times;

[0044] S4. Then dry the fiber paperboard impregnated with the impregnation solution in an oven at 80°C for 15 minutes, then take it out and put it in a porcelain boat, put it into a tube furnace and calcinate it under the protection of high-purity argon for 3.5 hours, the calcining temperature is 900°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com