Preparation method of liquid modified aromatic hydrocarbon petroleum resin

A technology for the modification of aromatic petroleum resins, applied in the field of petroleum resins, can solve problems such as increased environmental impact, color number of liquid resin products, and unstable performance such as average molecular weight melt viscosity, etc., to achieve improved production efficiency, good catalytic activity, and high efficiency. The effect of the polymerization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

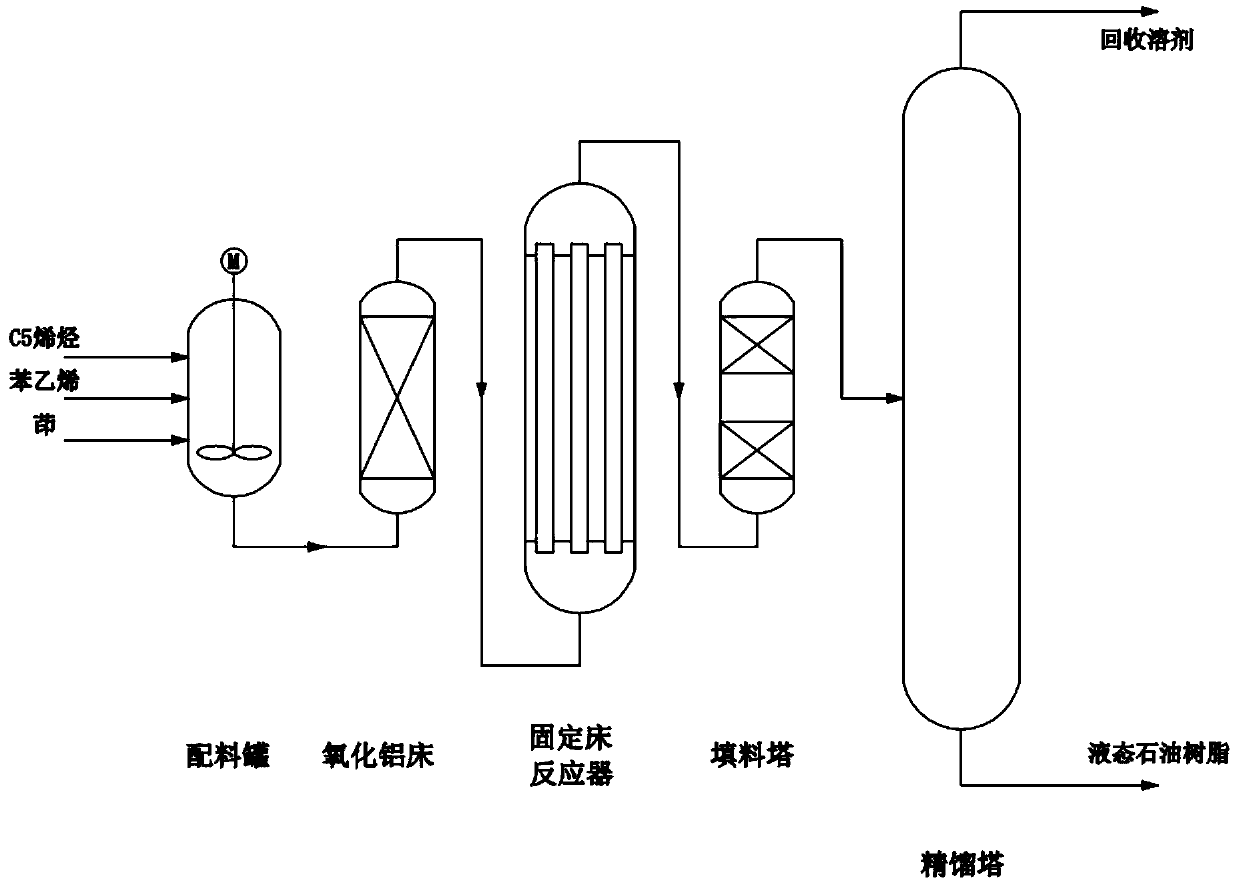

Method used

Image

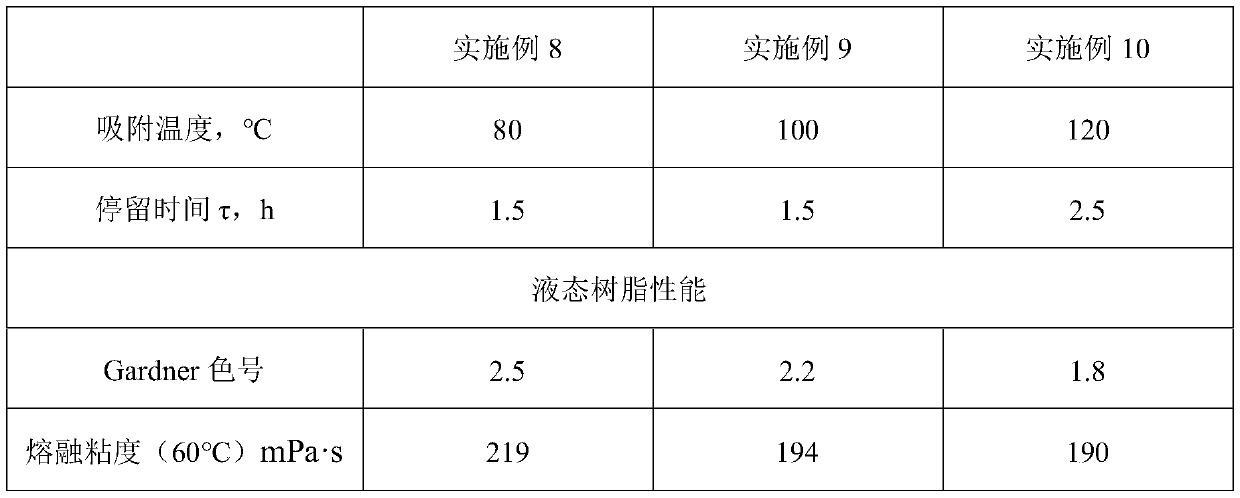

Examples

Embodiment 1

[0025] Prepare and mix indene, styrene and piperylene at a mass ratio of 1:0.25:0.1, and then uniformly mix with methylcyclohexane accounting for 30% of the total mass of the material to obtain a polymeric raw material, which is first dried and dehydrated by alumina to the raw material water The content is 110ppm; then the foamed ceramics load phosphotungstic acid H 6 P 2 W 18 o 62 Catalyzed polymerization to obtain a polymeric resin liquid, the reaction temperature is 45°C, the reaction pressure is 110kPa, and the reaction time is 8h. The above-mentioned resin liquid is filtered through a packing tower to remove impurities, and then enters a rectification tower, and the solvent is removed at a vacuum degree of -0.090MPa and a temperature of 185°C to obtain Gardner color number 3.0#, and a melt viscosity (60°C) of 175mPa·s Liquid petroleum resin. The resin has good compatibility with IR, BR rubber, etc., and improves the cohesive strength of its products.

Embodiment 2~5

[0027] In Examples 2-5, indene, styrene and different C5 olefins were prepared in a mass ratio of 1:0.25:0.1, and the rest of the process conditions were the same as in Example 1.

[0028] Example 2 Example 3 Example 4 Example 5 C5 Olefin Monomer Isoprene Cyclopentadiene Isoamylene Cyclopentene Gardner shade number, # 3.2 3.9 1.9 2.3 Melt viscosity(60℃)mPa·s 238 118 57 104 DACP cloud point, ℃ -13 3 -5 10

[0029] The DACP cloud point, that is, the cloud point of diacetone alcohol, is to mix the resin, xylene and diacetone alcohol evenly in an equal mass ratio to obtain a mixed sample; then the above sample is heated and cooled with the furnace, and the temperature when the solution is completely cloudy as a measure. This indicator reflects the polarity of the resin itself. Too high DACP cloud point will affect the initial compatibility with elastomers such as NR, SIS, SBS, SBR, etc., which will lead to the reductio...

Embodiment 6

[0033] Prepare and mix methylindene, α-methylstyrene and piperylene at a mass ratio of 1:0.40:0.05, and then uniformly mix with methylcyclohexane accounting for 35% of the total mass of the material to obtain a polymerization raw material, which is first oxidized The aluminum is dried and dehydrated until the water content of the raw material is 120ppm; then, the polymer resin liquid is obtained by catalytic polymerization of dodecaphosphomolybdic acid supported on foam ceramics, the reaction temperature is 60°C, the reaction pressure is 114kPa, and the reaction time is 5h. The above-mentioned resin liquid is filtered through a packed tower to remove impurities, and then enters a rectification tower, and the solvent is removed at a vacuum degree of -0.090MPa and a temperature of 185°C to obtain a Gardner color number of 0.9#, and a melt viscosity (60°C) of 267mPa·s Liquid petroleum resin. The resin has high melt viscosity and is suitable for toughening modification of high sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com