Making method for production technology regulations for green food highland barley

A technology of green food and production technology, applied in the fields of botanical equipment and methods, microbial treatment, biological organic part treatment, etc., can solve the problems of high labor intensity in field management, unscientific and reasonable steps, and insufficient growth. The effects of managing labor intensity and management costs, improving body immunity, and strong resistance to pests and diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

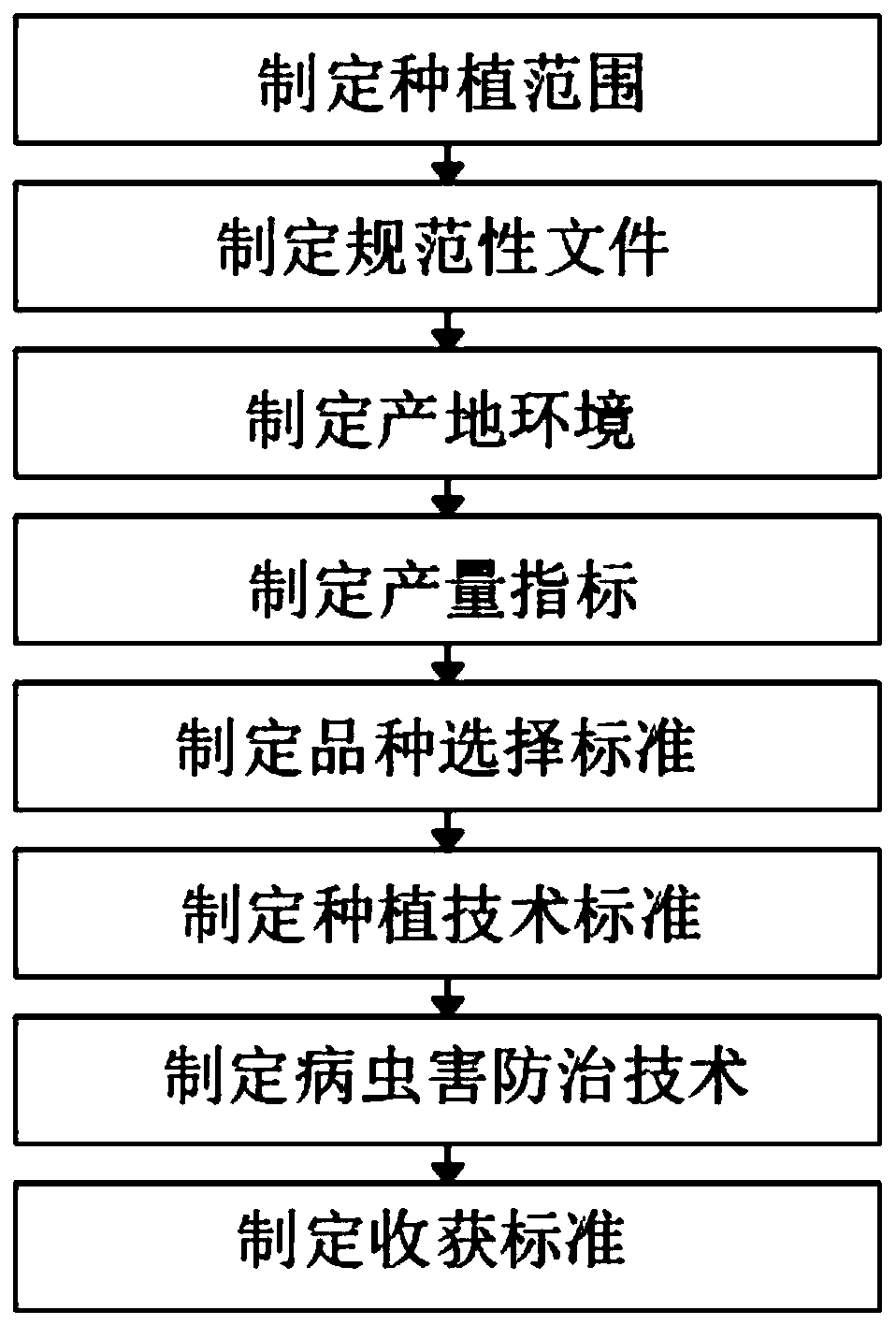

[0047] A method for formulating technical regulations for green food highland barley production, comprising the steps of:

[0048] S1. Formulate the planting range, which is an area suitable for cultivation with plateau continental climate characteristics;

[0049] S2. Formulate normative documents. The normative documents are based on GB4404.1 quality standards for crop seeds and cereal seeds; NY / T391 environmental technical conditions for green food origin; NY / T393 guidelines for the use of pesticides for green food; Guidelines; NY / T658 General Guidelines for Green Food Packaging; NY / T891 Green Food Barley and Barley; NY / T1054 Guidelines for Environmental Investigation, Monitoring and Evaluation of Green Food Origins; NY / T1055 Inspection Rules for Green Food Products; NY / T1056 Green Food Storage formulation of transport guidelines;

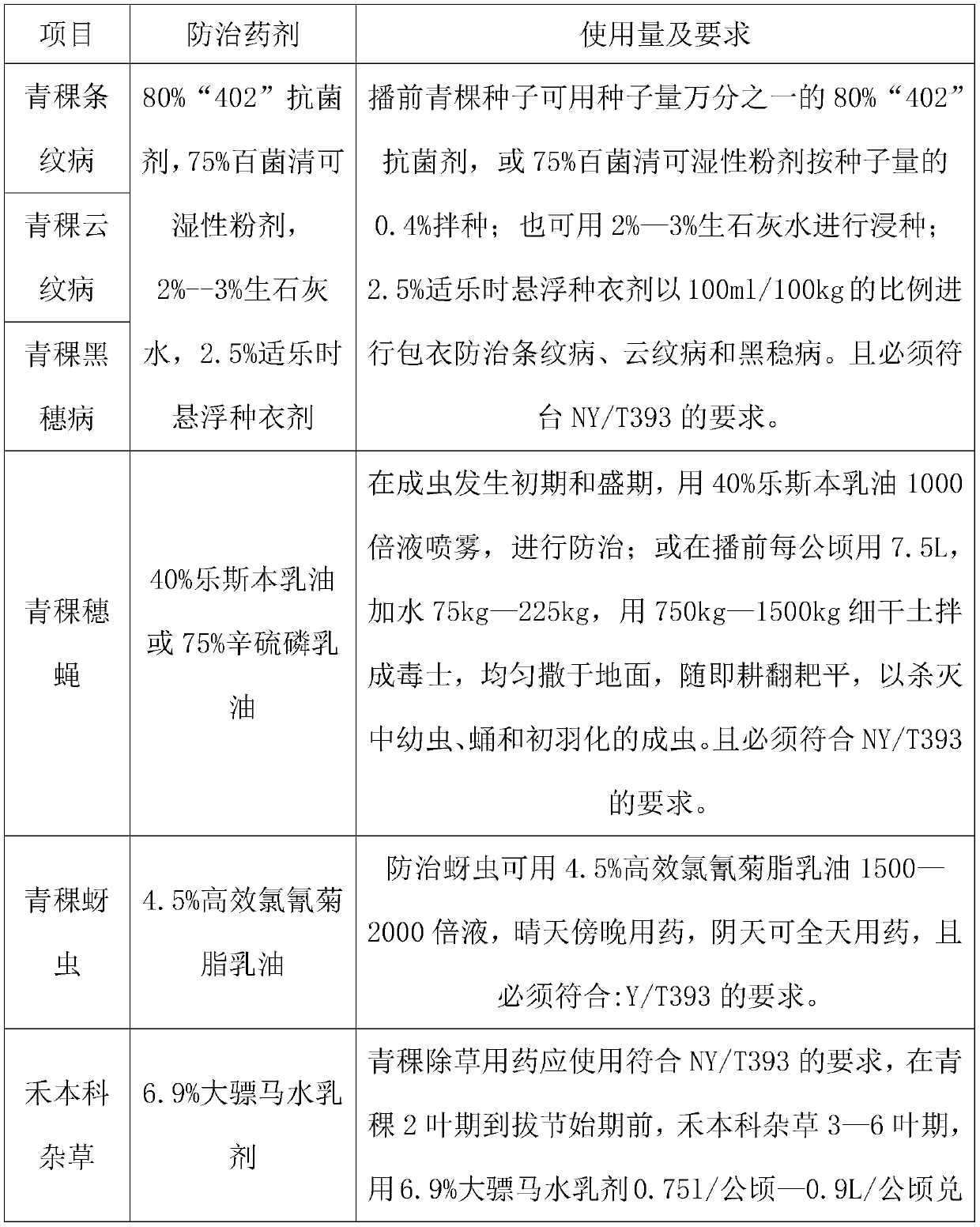

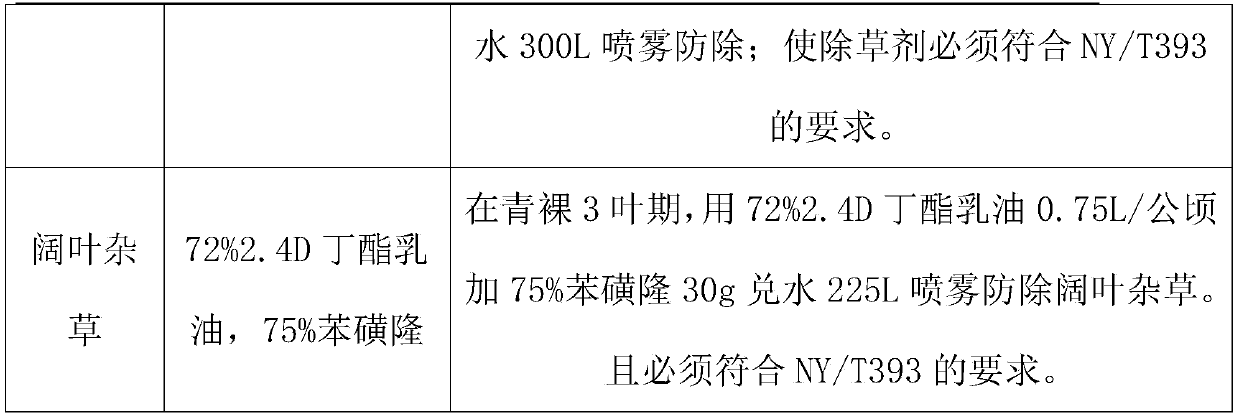

[0050] S3. Formulate the environment of the production area. The environmental conditions of the production area should meet the requirements ...

Embodiment 2

[0087] The difference from Example 1 is the preparation of the organic fertilizer, and its specific preparation method is as follows:

[0088] Weighing by weight: 150 parts of livestock manure, 80 parts of poultry manure, 80 parts of plant straw, 1 part of Bacillus subtilis, 1 part of photosynthetic bacteria, 1 part of lactic acid bacteria, 5 parts of yeast, 150 parts of water and boron, zinc, 15 parts of trace element fertilizer of molybdenum, iron, manganese and copper nutrients;

[0089] Step 2, crushing the weighed plant stalks into solid particles through a pulverizer;

[0090] Step 3. Combine the solid particles and the weighed livestock manure, poultry manure, plant straw, Bacillus subtilis, photosynthetic bacteria, lactic acid bacteria, yeast, water, trace amounts of nutrients containing boron, zinc, molybdenum, iron, manganese and copper Add all the elemental fertilizers into the mixer and stir evenly;

[0091] Step 4, taking out the uniformly stirred material in the ...

Embodiment 3

[0095] The difference from Example 1 is the preparation of the organic fertilizer, and its specific preparation method is as follows:

[0096] Weighing by weight: 200 parts of livestock manure, 100 parts of poultry manure, 100 parts of plant straw, 2 parts of Bacillus subtilis, 2 parts of photosynthetic bacteria, 2 parts of lactic acid bacteria, 6 parts of yeast, 200 parts of water and boron, zinc, 20 parts of trace element fertilizers of molybdenum, iron, manganese and copper nutrients;

[0097] Step 2, crushing the weighed plant stalks into solid particles through a pulverizer;

[0098] Step 3. Combine the solid particles and the weighed livestock manure, poultry manure, plant straw, Bacillus subtilis, photosynthetic bacteria, lactic acid bacteria, yeast, water, trace amounts of nutrients containing boron, zinc, molybdenum, iron, manganese and copper Add all the elemental fertilizers into the mixer and stir evenly;

[0099] Step 4, taking out the uniformly stirred material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com