Preparation method of modified molecular sieve loaded Pd catalyst and application of modified thereof in synthesis of dimethyl carbonate by gas phase process

A technology of dimethyl carbonate and molecular sieve, which is applied in the field of catalyst preparation, can solve problems such as poor safety, low catalyst selectivity, and reduced conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

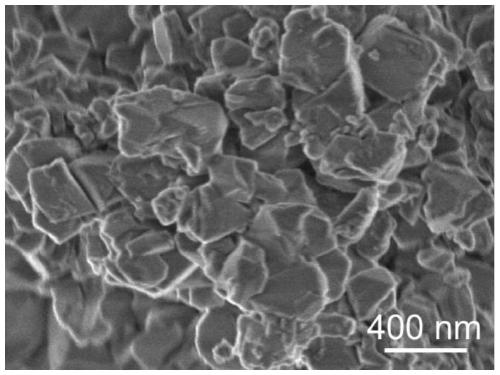

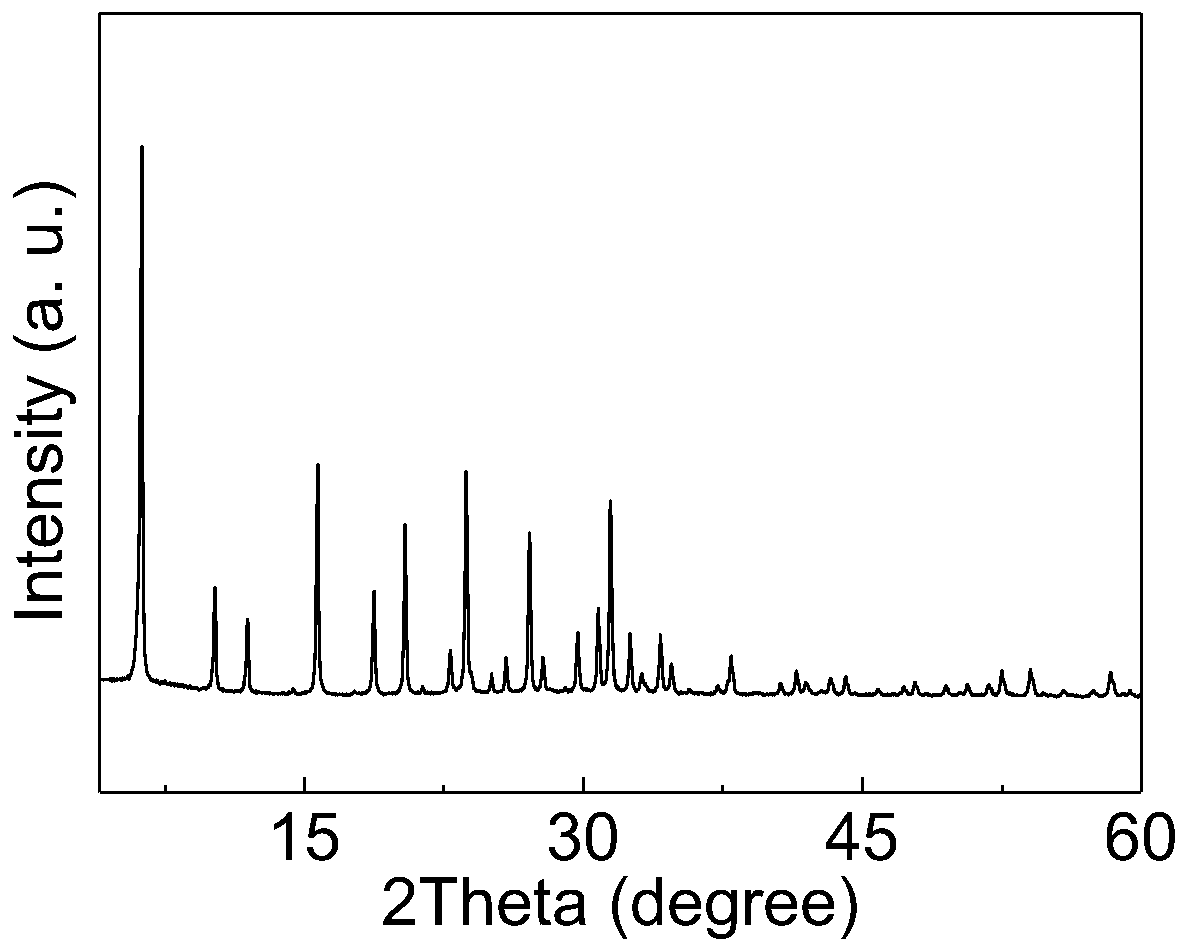

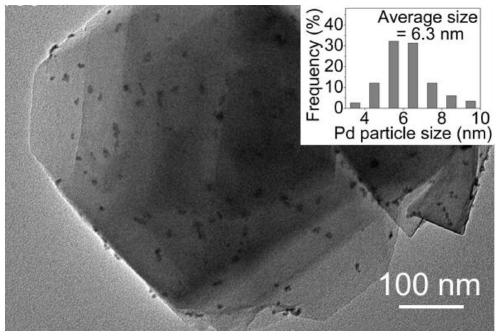

Image

Examples

Embodiment 1

[0039] 1) Using a mixed solution containing 0.02mol / L sodium bicarbonate and 0.03mol / L sodium chloride to pretreat the FAU molecular sieve at 20°C for 0.6 hours, wash, dry at 80°C for 4 hours, and roast at 155°C for 2 hours , to obtain a modified molecular sieve;

[0040] 2) Add the modified molecular sieve in step 1) to deionized water to form a suspension, use 0.25mmol / L dilute ammonia solution to dissolve palladium chloride to obtain a mixed solution, add the mixed solution dropwise to the suspension, and control the palladium element The mass ratio to the modified molecular sieve is 0.002:1, the pH is adjusted to 5.5 with hydrochloric acid aqueous solution, and the reaction is stirred at 6°C for 0.6 hours. After filtering and washing, dry at 10°C for 47 hours, and then use a muffle furnace to The heating rate of 0.25°C / min was raised to 115°C, and kept in the muffle furnace for 0.6 hours to obtain a Pd-loaded molecular sieve;

[0041] 3) Put the Pd-loaded molecular sieve ...

Embodiment 2

[0044] 1) FAU molecular sieves were pretreated at 40°C for 6.0 hours with a mixed solution containing 0.20mol / L acetic acid and 0.10mol / L oxalic acid, washed, dried at 80°C for 4 hours, and calcined at 300°C for 2 hours to obtain a modified Molecular sieve;

[0045] 2) Step 1) the modified molecular sieve is added to deionized water to form a suspension, and the dilute ammonia solution of 2.4mmol / L is used to dissolve palladium nitrate and palladium acetate to obtain a mixed solution, and the mixed solution is added dropwise to the suspension to control The mass ratio of palladium element to modified molecular sieve is 0.011:1, the pH is adjusted to 7.5 by using nitric acid and acetic acid aqueous solution, stirred and reacted at 35°C for 24 hours, filtered and washed, dried at 45°C for 24 hours, and then used The muffle furnace was raised to 180°C at a rate of 0.5°C / min, and kept in the muffle furnace for 2 hours to obtain a Pd-loaded molecular sieve;

[0046] 3) Put the Pd-...

Embodiment 3

[0049] 1) Pretreating the FAU molecular sieve with 0.48mol / L potassium chloride solution at 70°C for 22 hours, washing, drying at 80°C for 4 hours, and roasting at 400°C for 2 hours to obtain a modified molecular sieve;

[0050] 2) Add step 1) modified molecular sieve to deionized water to form a suspension, utilize 4.8mmol / L dilute ammonia solution to dissolve potassium chloropalladate and palladium chloride to obtain a mixed solution, and add the mixed solution dropwise to the suspension In the process, the mass ratio of palladium element to modified molecular sieve is controlled to be 0.024:1, the pH is adjusted to 8.0 by using hydrochloric acid aqueous solution, the reaction is stirred at 92°C for 46 hours, filtered and washed, dried at 90°C for 1.5 hours, and then Use a muffle furnace to raise the temperature to 240°C at a rate of 1.8°C / min, and keep it in the muffle furnace for 3.8 hours to obtain a Pd-loaded molecular sieve;

[0051] 3) Put the Pd-loaded molecular sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com