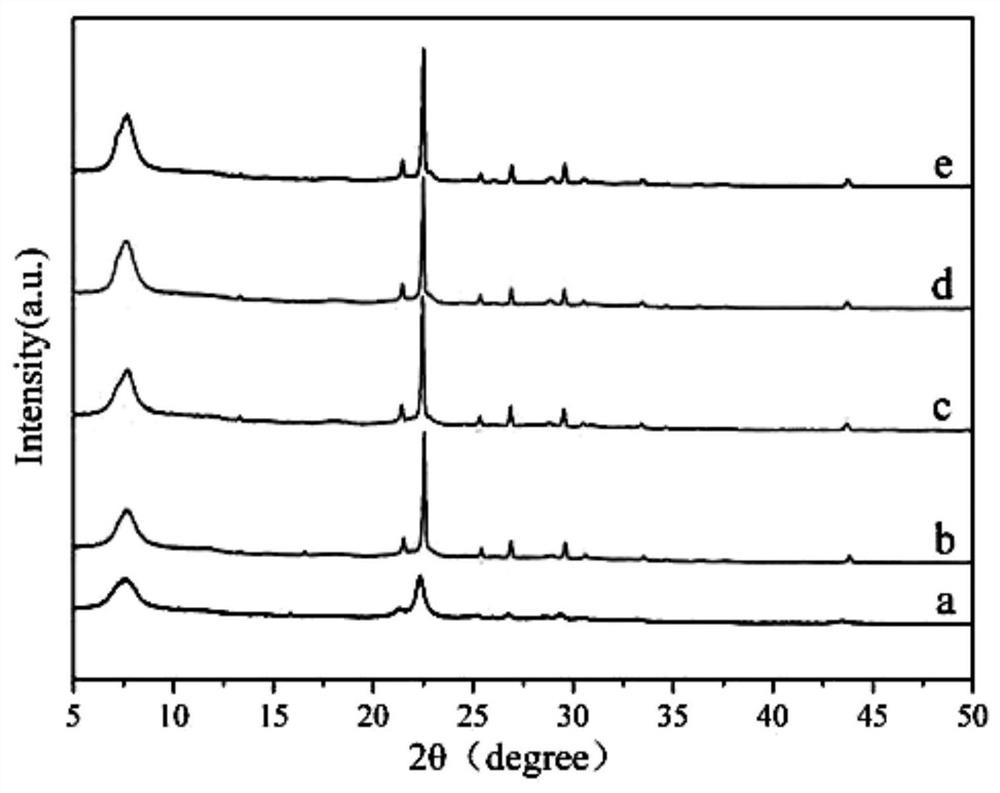

A kind of all silicon h-beta molecular sieve and its preparation method and application

A molecular sieve, silicon source technology, applied in molecular sieve and alkali exchange compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of increasing production costs, reducing product yield, and high ammonia nitrogen content, and achieving product yield improvement, The effect of high microporous specific surface area and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

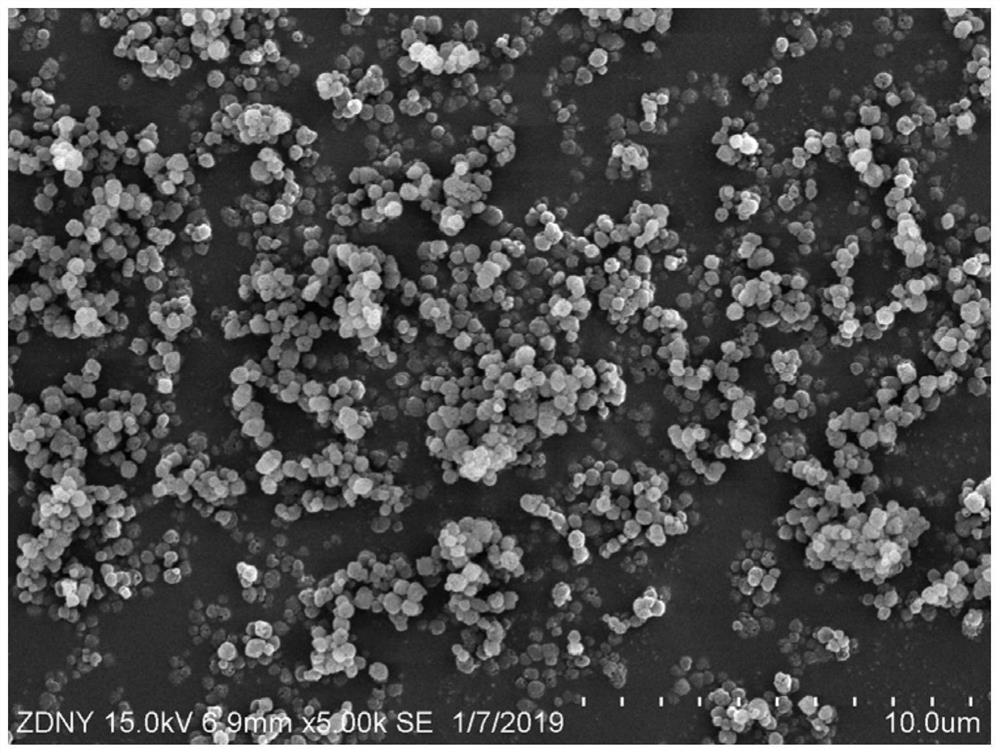

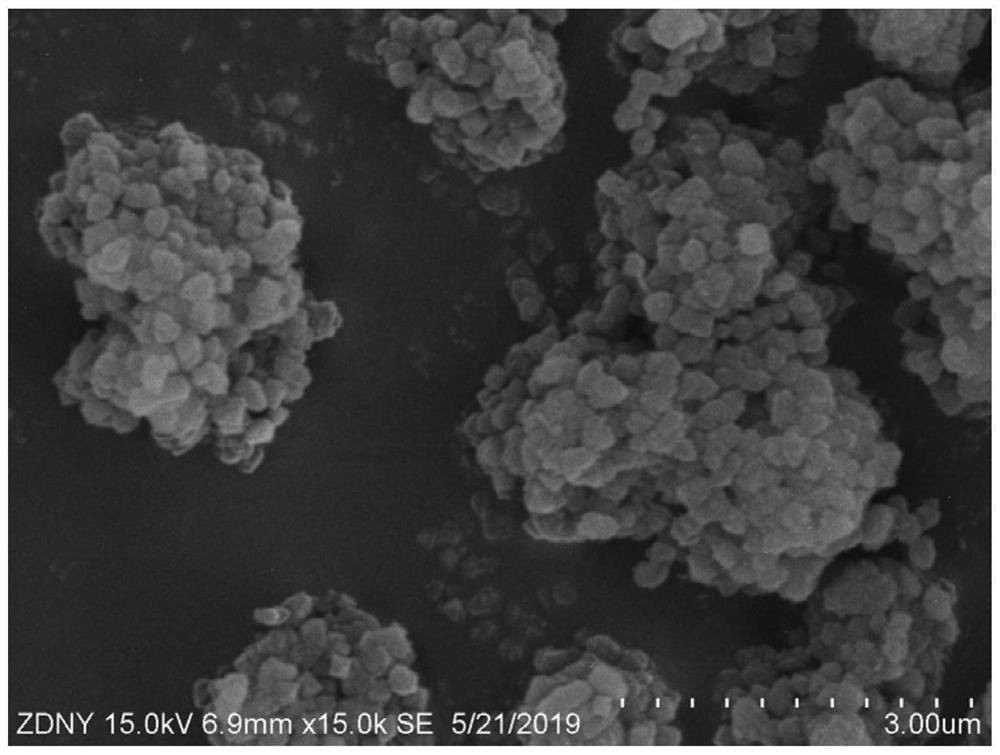

Embodiment 1

[0035] According to the molar ratio template (R): silicon source (SiO 2 ): crystallization aid (M): water (H 2 O): seed crystal (Y)=0.52:1:0.37:12.67:0.2, each raw material is taken by weighing, wherein template R is 30% tetraethylammonium hydroxide (TEAOH) and tetraethylammonium bromide (TEABr ) mixture (the molar ratio of the two is 2:1). The silicon source is silica sol, and the crystallization auxiliary agent M is hydrofluoric acid (HF). The seed crystal is a conventional H-BETA molecular sieve with a silicon-aluminum ratio of 25. Under the condition of stirring at room temperature, mix the silicon source and water, stir for 30 minutes until uniform, then add template agent R to the above solution, continue stirring for 30 minutes, then add crystallization auxiliary agent M to the gel, stir for 2 hours, and add to the gel Add conventional H-BETA molecular sieve seed crystals in small amounts in batches. Put the gel system into a high-pressure reactor with a PTFE liner,...

Embodiment 2

[0037] According to the molar ratio R:SiO 2 :M:H 2 O: Y = 0.56: 1: 0.4: 15: 0.25, each raw material was weighed, wherein the templating agent R was a mixture of 35% tetraethylammonium hydroxide (TEAOH) and tetraethylammonium chloride (TEACl) (two The molar ratio is 4:1). The silicon source is white carbon black. The crystallization auxiliary agent M is hydrofluoric acid (HF). Under the condition of stirring at room temperature, mix the silicon source and water, stir for 60 minutes until uniform, then add template agent R to the above solution, continue stirring for 60 minutes, add crystallization auxiliary agent M to the gel, stir for 1 hour, and add to the gel Add the dealuminated H-Beta molecular sieve seed crystals in small amounts in batches. Put the gel system into a PTFE-lined high-pressure reactor, raise it from room temperature to 165°C, and conduct crystallization treatment for 3 days. After washing and filtering to neutrality. Dry at 140°C for 4 hours, and then...

Embodiment 3

[0039] According to the molar ratio R:SiO 2 :M:H 2 O: Y = 0.6: 1: 0.35: 12.8: 0.15, each raw material was weighed, wherein template agent R was a mixture of 35% tetraethylammonium hydroxide (TEAOH) and tetraethylammonium fluoride (TEAF) (two The molar ratio is 5:1). The silicon source is tetraethyl orthosilicate, and the crystallization auxiliary agent M is hydrofluoric acid (HF). Under the condition of stirring at room temperature, mix the silicon source and water, stir for 12 hours until the tetraethyl orthosilicate is completely hydrolyzed, and release all ethanol and stir evenly, then add the template agent R to the above solution, continue stirring for 20 minutes, and then form a gel Add crystallization auxiliary agent M to the gel, and after stirring for 30 minutes, add dealuminated H-BETA molecular sieve seed crystals to the gel in small amounts. Put the gel system into a high-pressure reactor with a PTFE liner, raise the temperature from room temperature to 140°C, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com