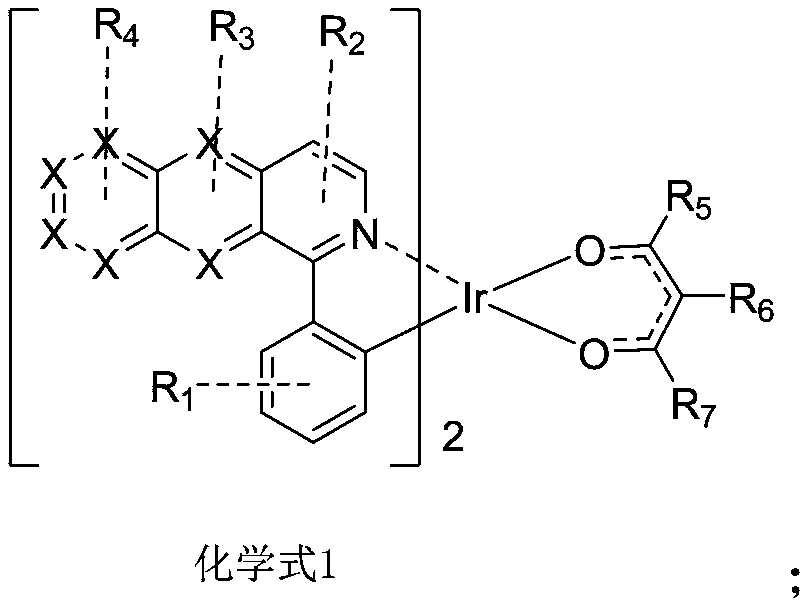

Organic iridium metal complex, preparation method and application thereof

A technology of iridium metal complexes and organic compounds, applied in indium organic compounds, platinum group organic compounds, organic chemistry and other directions, can solve problems such as restricting the development and application of organic phosphorous luminescent materials, and achieve luminous efficiency and brightness improvement, high yield, Ease of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

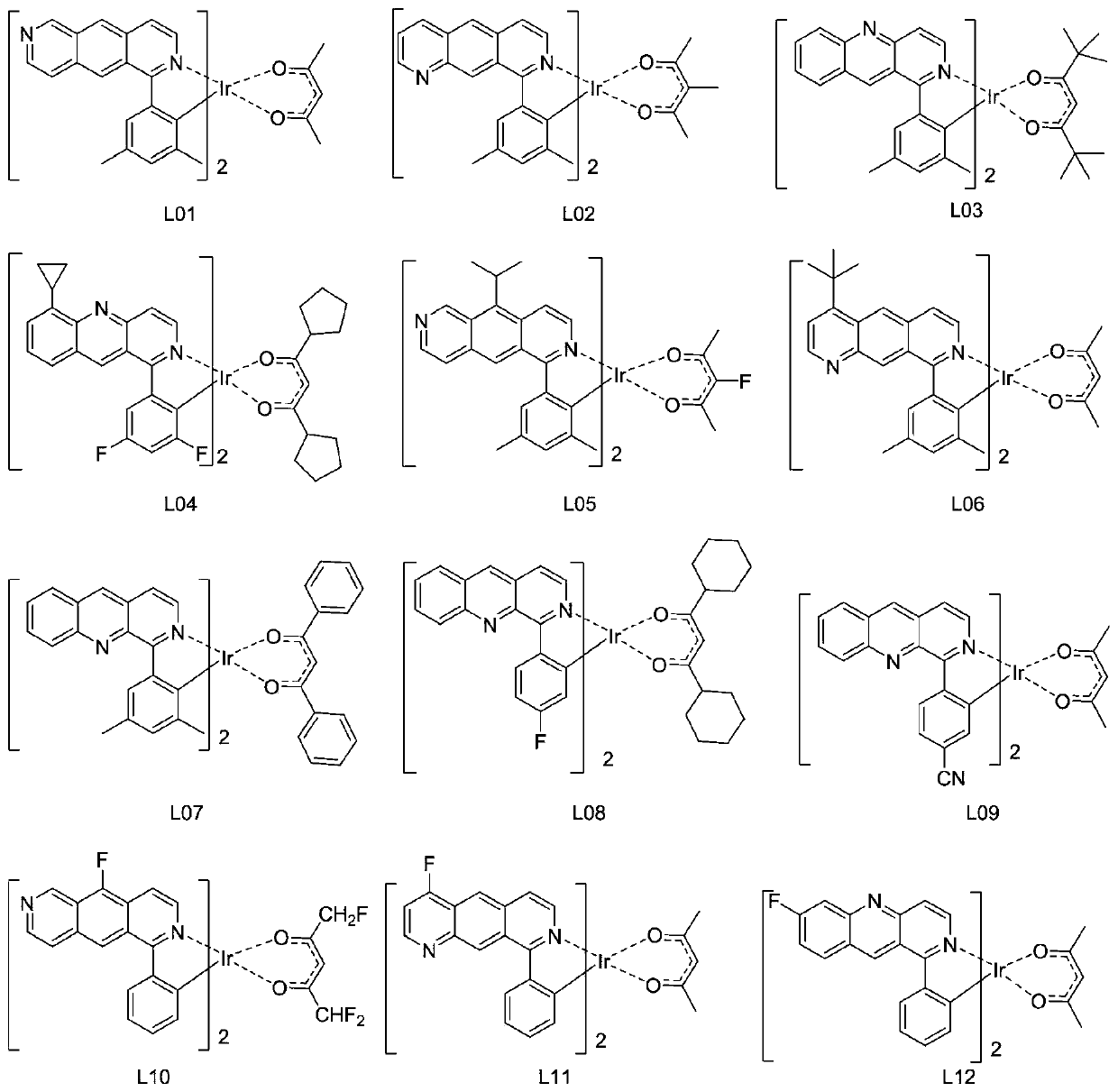

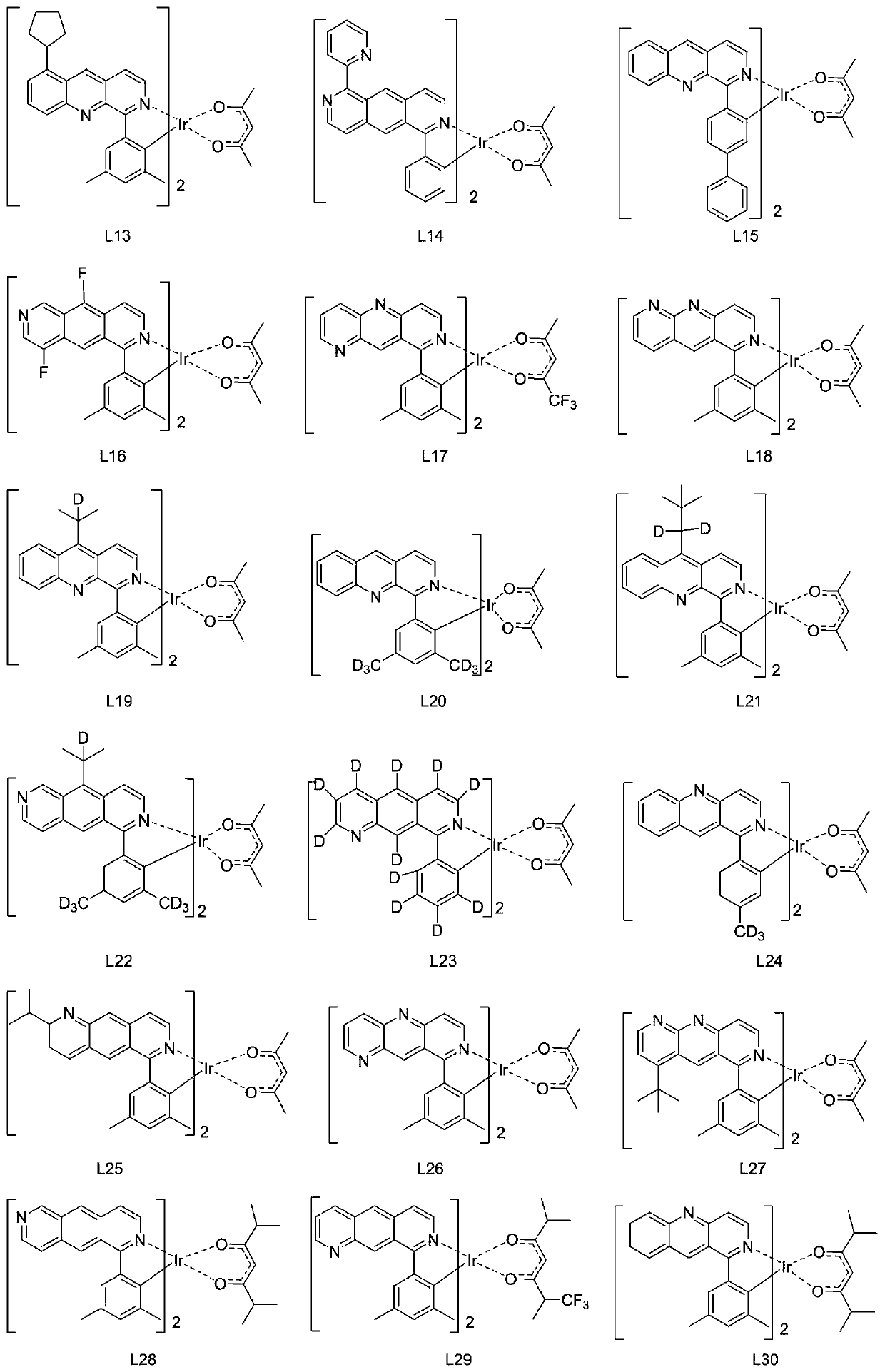

Examples

preparation example Construction

[0048] The embodiment of the present invention also discloses a preparation method of an organic iridium metal complex, comprising the following steps:

[0049] 1) Under an inert gas protection system, add solvent A to the mixed system of compound A and iridium trichloride, and reflux at 110-130°C for 20-28h, cool and filter, and wash the precipitate to obtain compound B;

[0050] 2) Add solvent B and base to the mixed system of compound B and compound C, react for 20-28h under the protection of inert gas, and the reaction temperature is 110-130°C, after the reaction, wash the precipitate with alcohol, dry it, and chromatograph, Product 1 is obtained;

[0051] Its synthetic route is as follows:

[0052]

[0053] For further optimizing technical scheme of the present invention, in step (1), solvent A is the mixture of ethylene glycol ether and pure water, and the volume ratio of ethylene glycol ether and pure water is: 3:1; Washing is to use water, dehydrated alcohol Wash ...

Embodiment 1

[0060] A kind of organic iridium metal complex (numbering is L01), concrete synthetic steps are as follows:

[0061] 1) Under nitrogen protection system, weigh A-01 (35.2mmol, 10g), IrCl 3 ·3H 2 O (14.1mmo15g) was put into the reaction system, after adding a mixed solution of 200mL ethylene glycol ether and 67mL pure water, reflux at 120°C for 24 hours under the protection of nitrogen, after the reaction was completed, cool to room temperature, a precipitate was precipitated, and the precipitate was suction filtered. Rinse and dry in sequence with water, absolute ethanol, and petroleum ether to obtain a red powder of bridging ligand B-01 (7.3 g, yield 65%);

[0062] 2) Weigh the intermediate B-01 (4.6mmol, 7.3g), add the ligand acetylacetone C-01 (13.8mmol, 1.5g), then add 150mL of ethylene glycol ether and potassium carbonate (6.3g) to the system Finally, under the protection of nitrogen, stir at 120°C for 24 hours. After the reaction, the precipitate was suction-filtered, ...

Embodiment 2

[0070] An organic iridium metal complex (numbered as L17), the specific synthesis steps are as follows:

[0071] 1) Under nitrogen protection system, weigh A-17 (35mmol, 10g), IrCl 3 ·3H 2 O (16mmol, 5.6g) was put into the reaction system, after adding a mixed solution of 300mL ethylene glycol ether and 100mL pure water, refluxed at 110°C for 28 hours under the protection of nitrogen, and then cooled to room temperature, there was precipitation, and then the precipitate was pumped Filter, rinse and dry with water, absolute ethanol, and petroleum ether successively to obtain bridging ligand B-17 (7.6 g, yield 60%) of red powder;

[0072] 2) Weigh intermediate B-17 (4.8mmol, 7.6g), add ligand C-17 (14.4mmol, 2.2g), and then add ethylene glycol ether 150mL and potassium carbonate (6.6g) to the system, Under the protection of nitrogen, stir at 123°C for 20 hours. After the reaction, the precipitate was suction-filtered, washed with alcohol, dried, and dichloromethane was used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com