Wettable carbon cathode for aluminum electrolysis as well as preparation method and application thereof

A wettability and aluminum electrolysis technology is applied in the field of new cathode materials for aluminum electrolysis cells and their preparation, which can solve the problems of restricting the popularization and application of wettable cathodes, uneven thermal expansion coefficient and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

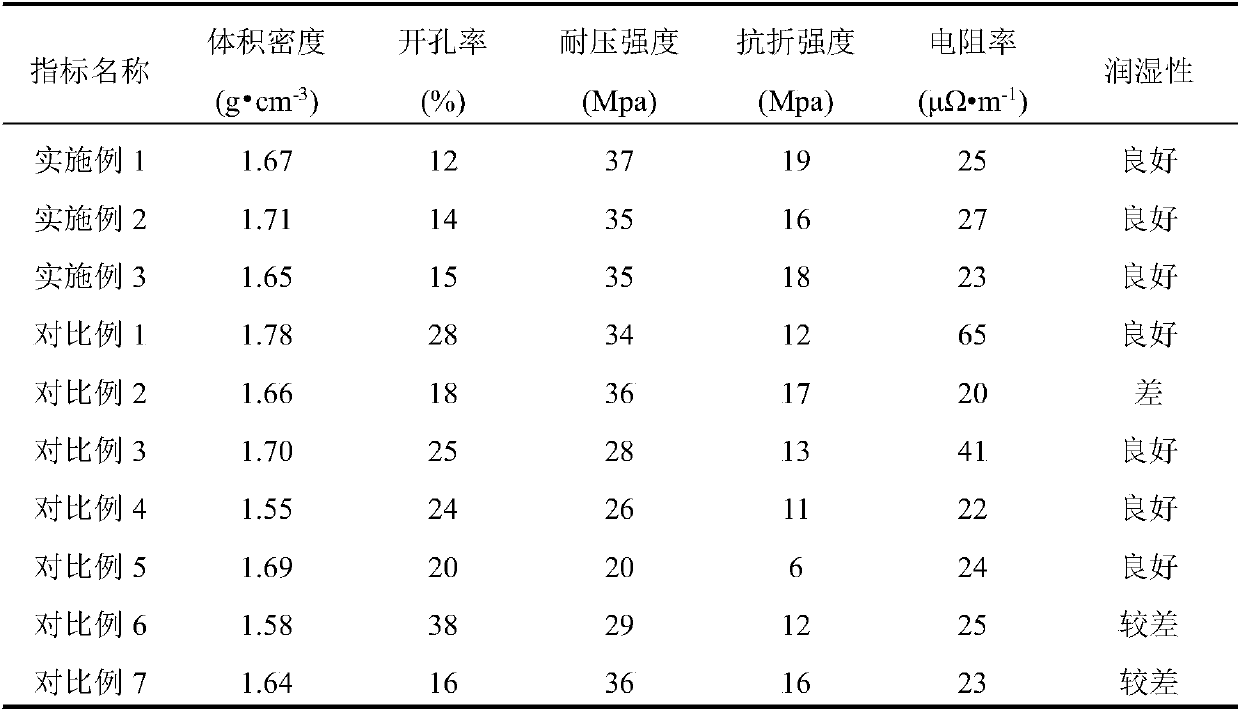

Examples

Embodiment 1

[0068] Step (1): The raw materials are mixed according to the molar ratio of elemental carbon: elemental nitrogen: elemental phosphorus = 92:5:3, and the nitrogen source is converted into the mass of the corresponding substance according to three times the molar ratio. The nitrogen source is combined by pyridine and ammonium carbonate according to the mass ratio of 2:1; the phosphorus source is added according to the mass ratio of 4 times the molar ratio converted into the corresponding substance, and the phosphorus source is combined by phosphonate and phosphoric acid according to the mass ratio of 3:1; the main body The carbon material is composed of graphite: soft carbon material: hard carbon material = 65:25:10 according to the mass ratio, wherein the soft carbon material precursor is composed of petroleum coke and coal tar pitch according to the mass ratio of 5:1, and the hard carbon material precursor is composed of phenolic Resin and polystyrene are composed according to...

Embodiment 2

[0089] Step (1): The raw materials are mixed according to the molar ratio of elemental carbon: elemental nitrogen: elemental phosphorus = 90:6:4, and the nitrogen source is converted into the mass of the corresponding substance according to 2.5 times the molar ratio. The nitrogen source is combined by ammonium chloride and ammonium carbonate according to the mass ratio of 1:2; the phosphorus source is added according to the mass ratio of 4.5 times the molar ratio converted into the corresponding substance, and the phosphorus source is combined by sodium hydrogen phosphate and phosphoric acid according to the mass ratio of 2:1 ;The main carbon material is composed of graphite:soft carbon material:hard carbon material=70:15:15 according to the mass ratio, wherein the soft carbon material precursor is composed of pitch coke and coal tar pitch according to the mass ratio of 5:2, and the hard carbon material precursor It is composed of epoxy resin and polystyrene propylene according...

Embodiment 3

[0094] Step (1): The raw materials are mixed according to the molar ratio of elemental carbon: elemental nitrogen: elemental phosphorus = 88:7:5, and the nitrogen source is converted into the mass of the corresponding substance according to 3 times the molar ratio. The nitrogen source is combined by pyridine and pyrrole according to the mass ratio of 1:1; the phosphorus source is added according to the mass ratio of 3.5 times the molar ratio converted into the corresponding substance, and the phosphorus source is combined by phosphonate and phosphine according to the mass ratio of 3:1; the main body The carbon material is composed of graphite: soft carbon material: hard carbon material = 70:20:10 according to the mass ratio, wherein the soft carbon material precursor is composed of anthracite and coal tar pitch according to the mass ratio of 4:1, and the hard carbon material precursor is composed of epoxy Resin and polyethylene are composed according to the mass ratio of 2:1. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com