Compound polyethylene glycol electrolyte granule and preparation method thereof

A polyethylene glycol and electrolyte technology, applied in the field of medicine, can solve the problems of difficult mixing, tedious patient compliance, easy secondary layering, etc., and achieve the effects of simple production process, controllable quality and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of compound polyethylene glycol electrolyte granules

[0038] 1. Formula (prepared based on 5kg of total materials per batch), as shown in Table 1:

[0039] Table 1

[0040] Polyethylene glycol 4000 6400 copies Sodium sulfate 570 copies Sodium chloride 146 copies Potassium chloride 75 servings Sodium bicarbonate 168 copies

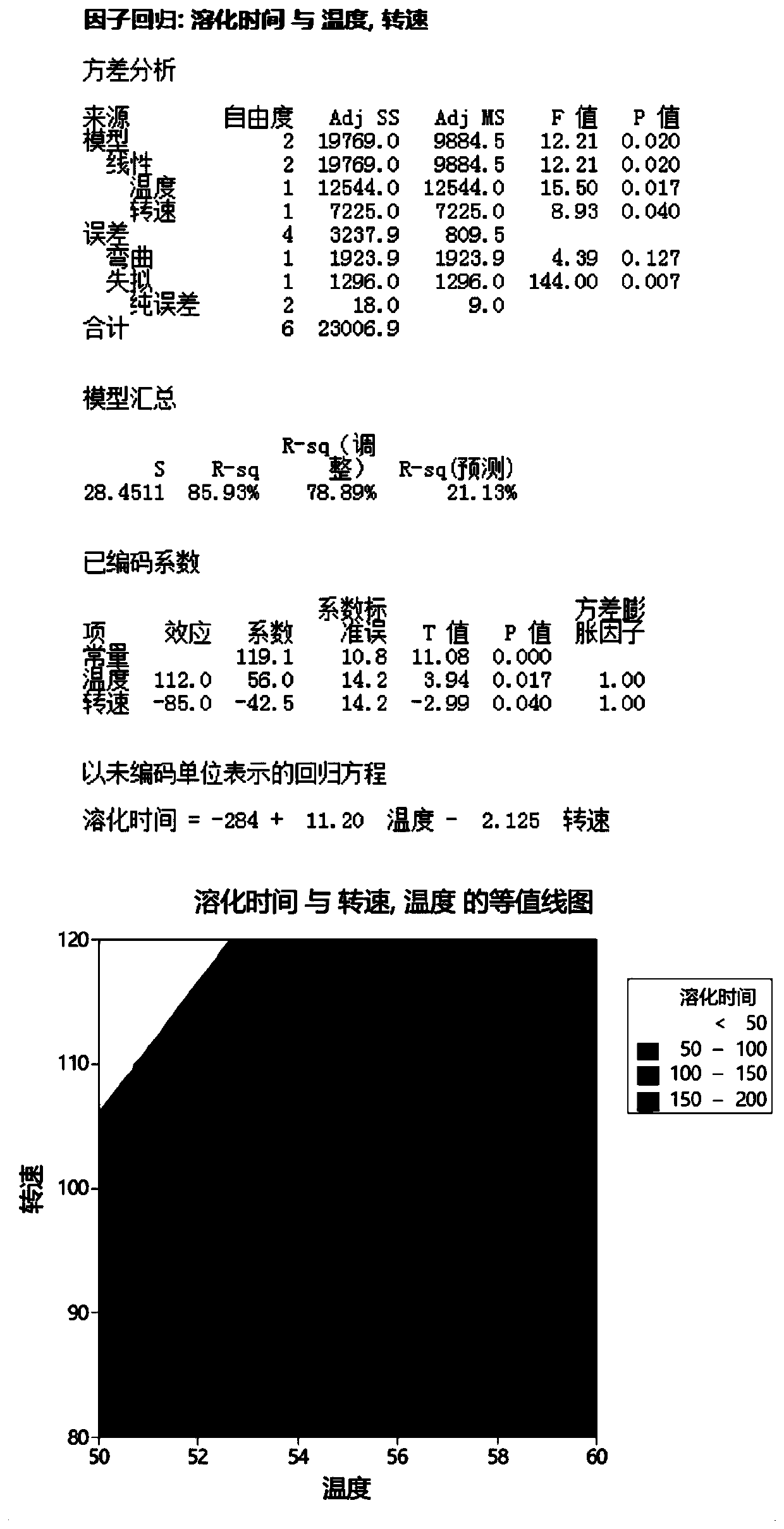

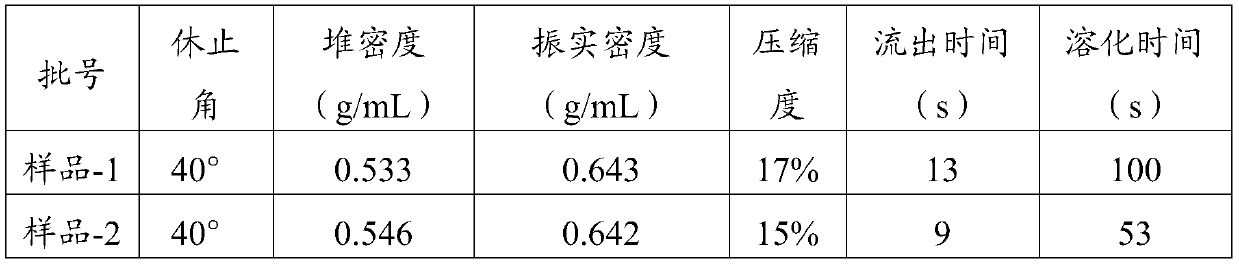

[0041] Preparation method: Mix the above-mentioned prescription amount of materials, and use a hot melt extruder for melt granulation. The hot melt temperature and screw speed are shown in Table 2 below:

[0042] Table 2

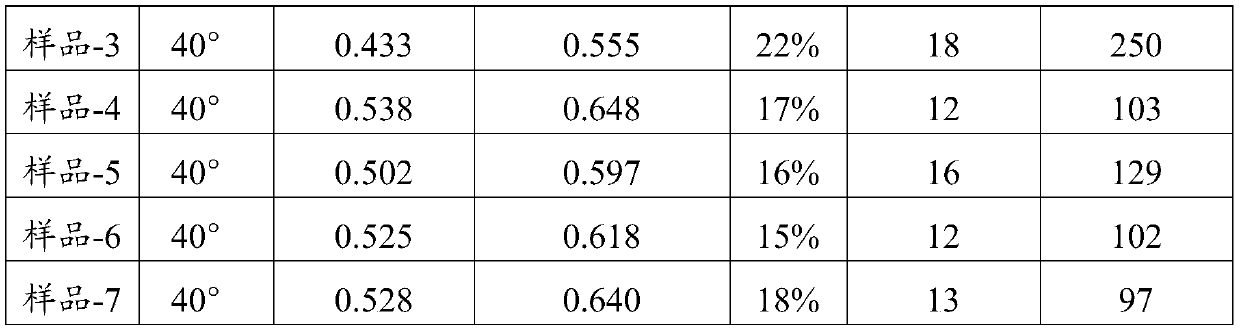

[0043] batch number Melting temperature (℃) Screw speed (rpm) Sample-155100 Sample-250120 Sample-36080 Sample-455100 Sample-560120 Sample-65080 Sample-755100

[0044] After the mixed material is pelletized by a hot melt extrusion machine, the pellets are pelletized through a 0.85μm pore size screen using a pelletizer, and packaged in aluminum-plastic composite film bags at 73.59g / bag to complete the ...

Embodiment 2

[0053] Example 2 Preparation of compound polyethylene glycol electrolyte granules

[0054] Recipe (prepared based on 5kg of total materials per batch), as shown in Table 4:

[0055] Table 4

[0056] Polyethylene glycol 4000 6400 copies Sodium sulfate 570 copies Sodium chloride 146 copies Potassium chloride 75 servings Sodium bicarbonate 168 copies

[0057] Preparation method: pass polyethylene glycol 4000 through a 40-mesh sieve for use, and sodium sulfate, sodium chloride, potassium chloride, and sodium bicarbonate through a 60-mesh sieve for use. Weigh according to the above prescription, put it into a single-arm mixer, and mix with the parameters in Table 5 below.

[0058] table 5

[0059] batch number Mixing speed Mixing time Sample-8 10rpm 5min Sample-9 10rpm 10min Sample-10 10rpm 15min

Embodiment 3

[0060] Example 3 Inspection of the uniformity of chloride ion content

[0061] Use the chloride ion content as an indicator to test the content uniformity. The detection method of chloride ion content refers to the detection method of sodium chloride in "National Drug Standard Compound Polyethylene Glycol Electrolyte Powder" (WS1-(X-229)-2004Z). The results are shown in Table 6 below. Among them, A+2.2S≤15 are qualified products.

[0062] Table 6

[0063] batch number content(%) RSD(%) A+2.2S Sample-197.71.184.8 Sample-296.81.045.4 Sample-398.41.063.9 Sample-499.51.914.7 Sample-597.52.738.4 Sample-699.13.839.3 Sample-7100.13.057.0 Sample-881.87.1931.2 Sample-981.71.8921.7 Sample-1085.828.6668.6

[0064] It can be seen from the results that the materials (polyethylene glycol 4000, sodium chloride, potassium chloride, sodium sulfate, sodium bicarbonate) in the compound polyethylene glycol electrolyte powder are directly mixed, and the content of the product obtained is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com