Method for preparing vinyl chloride by reaction between acetylene and dichloroethane

A technology of ethylene dichloride and vinyl chloride, applied in the field of vinyl chloride preparation, can solve the problems of low energy utilization rate, low catalyst activity, insufficient satisfaction, etc., and achieves a significant improvement in industrial application value, excellent catalytic performance, and a solution to the problem. The effect of environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

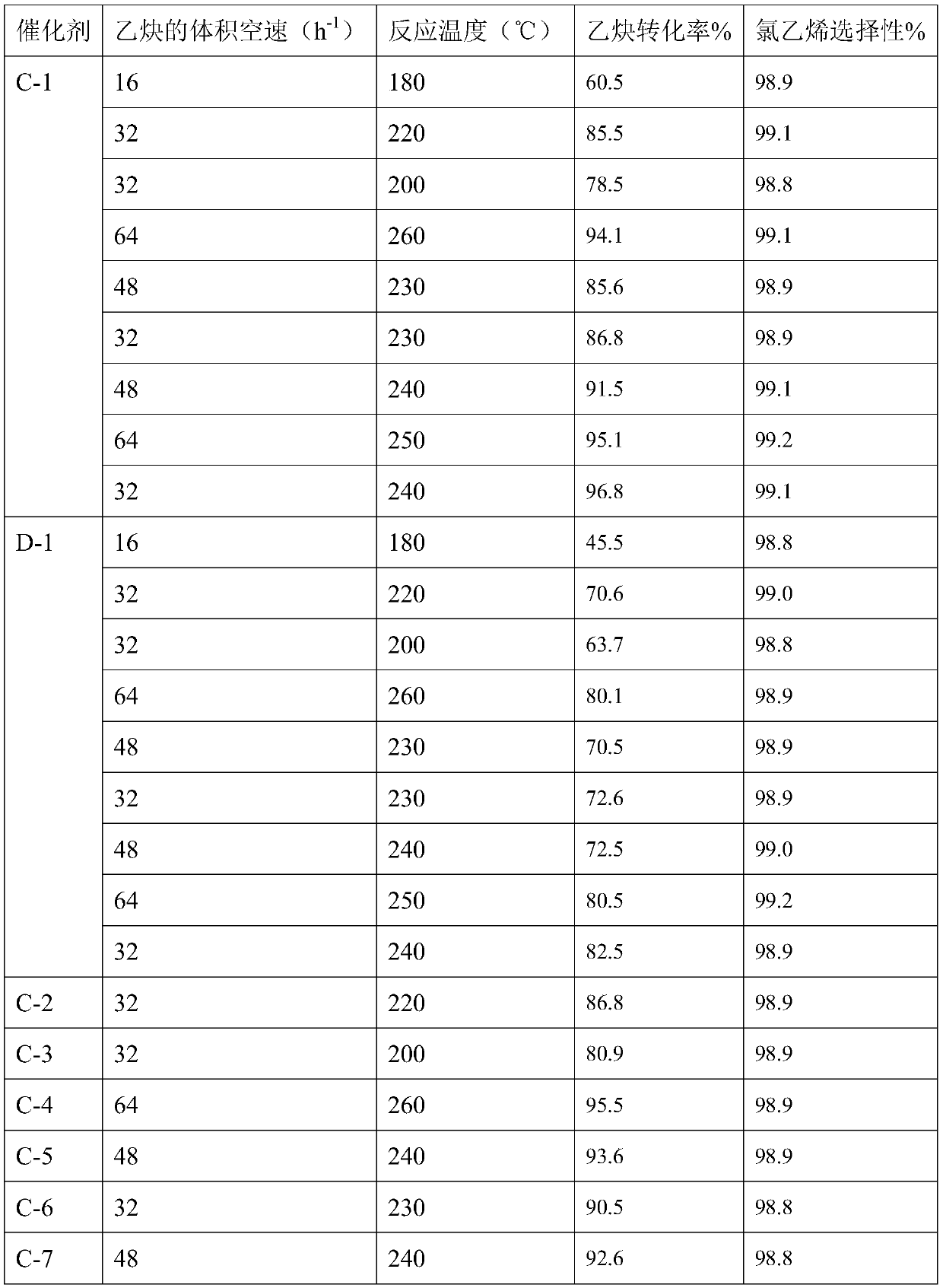

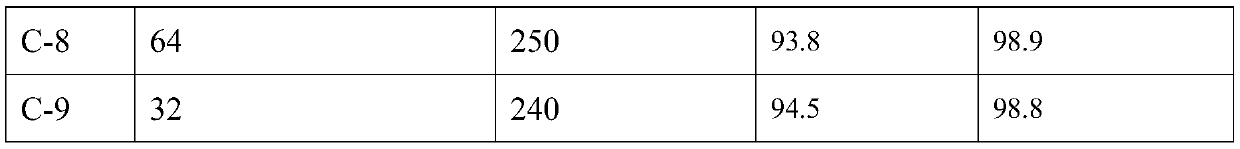

Examples

Embodiment 1

[0039] Example 1: Preparation of biomass-based nitrogen-doped carbon catalyst

Embodiment 11

[0041] 1) Wash, dry, and crush the bamboo processing waste to 20 mesh, and set aside;

[0042] 2) Mix 10g of bamboo powder, 10g of acrylamide and 10g of zinc chloride, add an equal volume of water and stir evenly, vacuum impregnate for 10 hours, then concentrate the impregnation system under reduced pressure, and dry the concentrate at 120°C to obtain impregnated modified sex;

[0043] 3) Carbonize the impregnated modified product at 1000°C for 2 hours in a nitrogen gas atmosphere, cool to room temperature, and wash the cooled carbonized product with 10% dilute hydrochloric acid (to remove excess zinc chloride, wash into the carbonized product Zinc ion concentration is lower than 100ppm), washed with deionized water until neutral, and then dried at 120°C to obtain the biomass-based nitrogen-doped carbon catalyst, abbreviated as C-1.

Embodiment 12

[0045] 1) Wash, dry, and crush the wood processing waste to 20 meshes, and set aside;

[0046] 2) Mix 10g of wood powder, 5g of urea and 15g of zinc chloride, add an equal volume of water and stir evenly, vacuum impregnate for 10 hours, then concentrate the impregnation system under reduced pressure, and dry the concentrate at 120°C to obtain impregnation modification thing;

[0047] 3) Carbonize the impregnated modified product at 800°C for 4 hours in a nitrogen gas atmosphere, cool to room temperature, and wash the cooled carbonized product with 10% dilute hydrochloric acid (to remove excess zinc chloride, wash into the carbonized product The concentration of zinc ions is lower than 100ppm), washed with deionized water until neutral, and then dried at 120° C. to obtain the biomass-based nitrogen-doped carbon catalyst, abbreviated as C-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com