Organic liquid crystal friction modifiers with alkyl end chains and preparation method thereof

A friction modifier and organic technology, applied in the field of lubricants, can solve the problems of great influence of anti-wear and anti-friction effects, differences in tribological properties, etc., and achieve the effects of strong low temperature solubility, good lubricating performance, and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

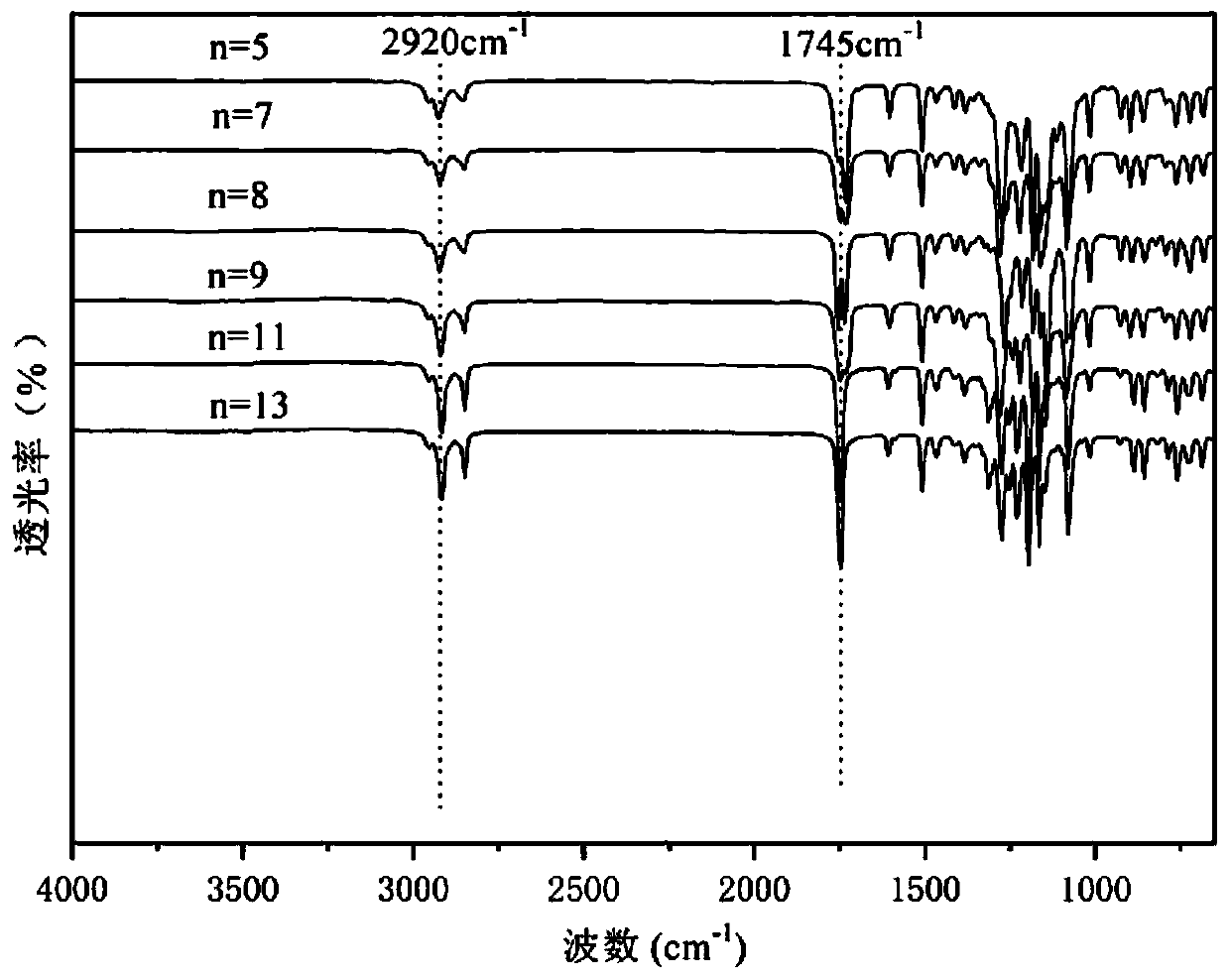

Method used

Image

Examples

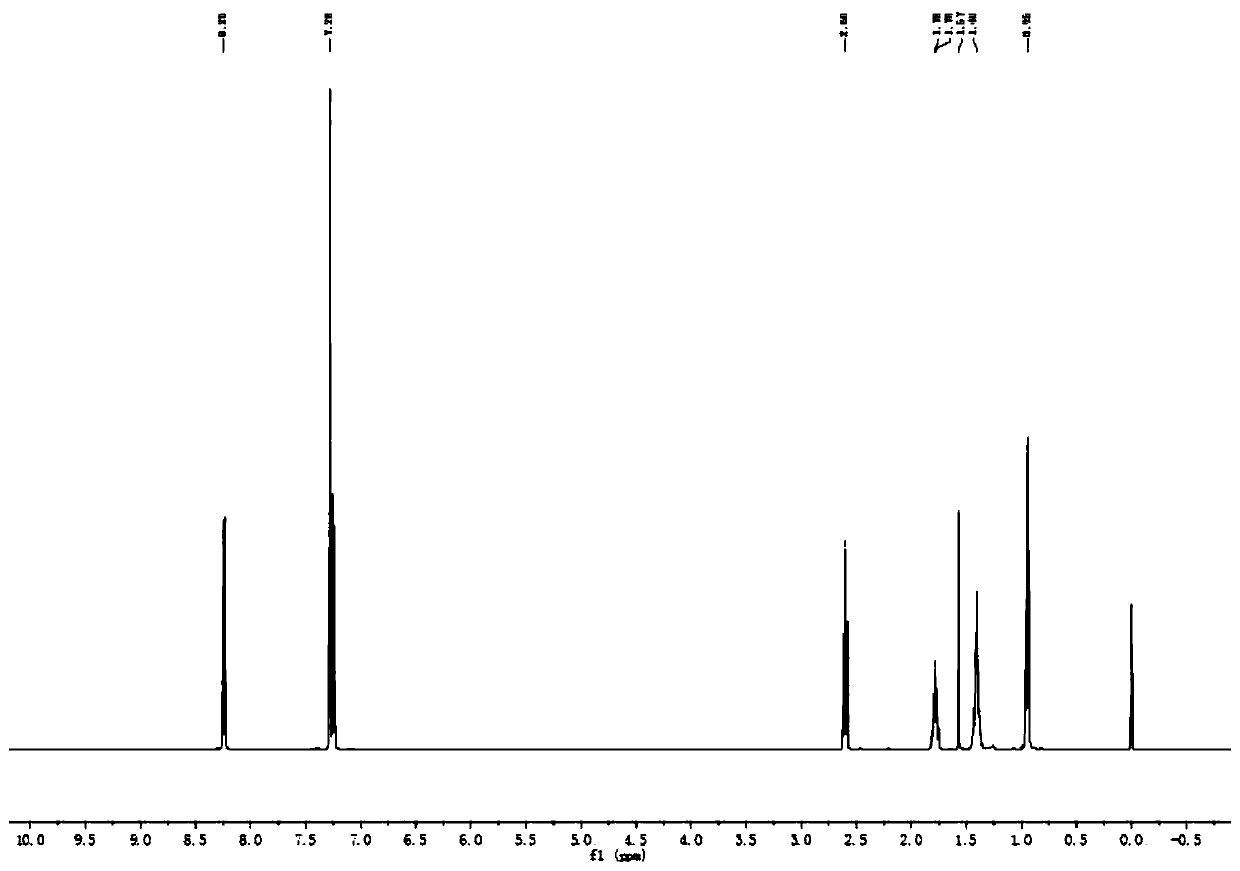

Embodiment 1

[0034] The compound preparation of n=6 in the embodiment 1 formula (I)

[0035] Put 34.5g of p-hydroxybenzoic acid and 13.8g of hydroquinone into a 500mL three-necked bottle, and pour 0.5g of p-toluenesulfonic acid and 300mL of solvent toluene into the bottle. Install an oil-water separator above the three-necked bottle, raise the temperature to 70°C, keep the temperature constant for 30 minutes, then gradually raise the temperature to reflux, and react for 30 hours. After the reaction was completed, the crude product was obtained by filtration. The crude product was recrystallized from absolute ethanol to obtain intermediate product A with a yield of 82% and a measured melting point of 340°C.

[0036] Put 2.97g of n-heptanoic acid and 7g of dicyclohexylcarbodiimide (DCC) in 100mL of dioxane, magnetically stir until completely dissolved, and cool to -20°C in an ice-salt bath. Dissolve 2g of intermediate product A and 0.37g of 4-dimethylaminopyridine (DMAP) in 50mL of dioxane...

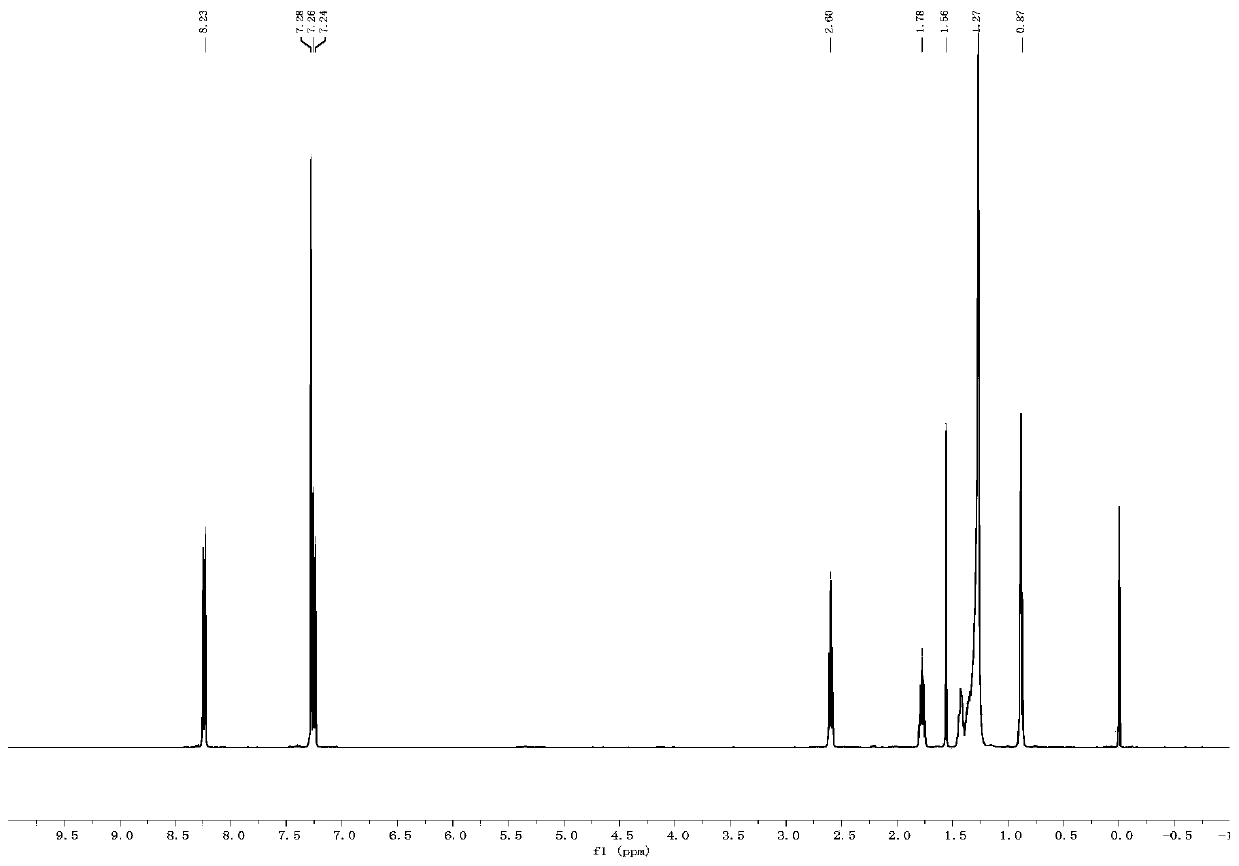

Embodiment 2

[0038] The compound preparation of n=8 in the embodiment 2 formula (I)

[0039] Put 3.61g of nonanoic acid and 7.1g of dicyclohexylcarbodiimide (DCC) in 100mL of dimethylformamide, magnetically stir until completely dissolved, and cool to -20°C in an ice-salt bath. Dissolve 2g of intermediate product A and 0.37g of 4-dimethylaminopyridine (DMAP) in 50mL of dimethylformamide, and slowly add it dropwise to the reaction system, and carry out the reaction at 0-10°C for 24 hours, and then naturally rise to room temperature React for 10 hours. After the reaction was complete, 3 mL of deionized water was added to the flask to quench the reaction. The reaction solution was extracted and washed with 1M hydrochloric acid solution, saturated sodium bicarbonate solution and saturated sodium chloride solution respectively, and the collected organic layer was rotary evaporated to remove the solvent to obtain a crude product. The crude product was recrystallized with absolute ethanol at 50...

Embodiment 3

[0041] Preparation of the compound of n=9 in the formula (I) of embodiment 3

[0042] Put 3.93g of n-decanoic acid and 6.1g of dicyclohexylcarbodiimide (DCC) in 100mL of dimethylformamide, magnetically stir until completely dissolved, and cool to -20°C in an ice-salt bath. Dissolve 2g of intermediate product A and 0.37g of 4-dimethylaminopyridine (DMAP) in 50mL of dimethylformamide, and slowly add it dropwise to the reaction system, and carry out the reaction at 0-10°C for 24 hours, and then naturally rise to room temperature React for 10 hours. After the reaction was complete, 3 mL of deionized water was added to the flask to quench the reaction. The reaction solution was extracted and washed with 1M hydrochloric acid solution, saturated sodium bicarbonate solution and saturated sodium chloride solution respectively, and the collected organic layer was rotary evaporated to remove the solvent to obtain a crude product. The crude product was recrystallized with absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com