Preparation method and application of EDDS lyase immobilized enzymes

A technology of immobilizing enzymes and lyases, applied in biochemical equipment and methods, immobilized on or in inorganic carriers, immobilized on/in organic carriers, etc., can solve the problem of reducing the synthesis efficiency and transformation capacity of EDDS. problems such as poor enzyme activity, high conversion rate, and improved operability are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

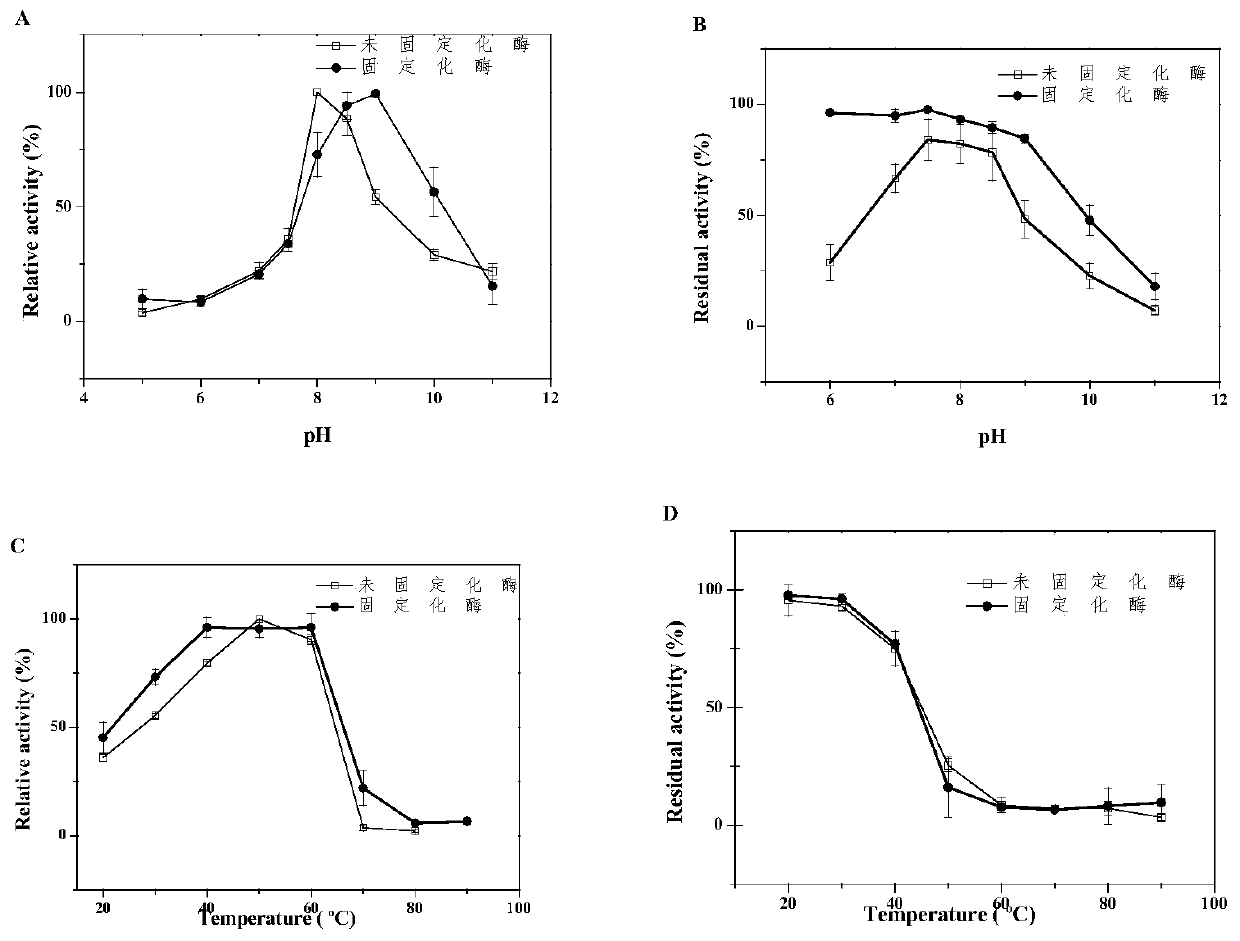

Method used

Image

Examples

Embodiment 1

[0035] Escherichia coli BL21 (DE3) / pTZU-27 (genetically engineered bacteria with EDDS lyase of His-tag) single colony was inoculated in a 15mL test tube, the plasmid pTZU-27 contained the nucleic acid sequence SEQ ID NO.1, and 30 μg / mL ampicillin 5ml-LB, cultured at a constant temperature of 37°C, after overnight culture, inoculated 1mL cells in 40mL TB medium (2.4% yeast extract, 1.2% trypsin, 0.4% glycerol, 17mmol / L K 2 PO 4 、72mmol / L KH 2 PO 4 ), and 50mg / mL ampicillin was added to a 500mL flask. After 4 hours, the culture was transferred to 2.0L TB medium in a 3L fermenter. After 600 reaches about 1, lower the temperature to 25°C, then add 150mL 20% (w / v) lactose solution to induce culture, keep the air flow at 1.0vvm, adjust the stirring speed to keep the dissolved oxygen (DO) above 20%, At the end of 20 hours of fermentation, centrifuge the fermentation broth at 10000×g, store the cells at -20°C, suspend 30 grams of cells in 270mL water, homogenize the bacterial su...

Embodiment 2

[0037] Take 1 mL of the crude enzyme solution obtained from the cultivation in Example 1 above and 1 mL of Binding / wash buffer (50 mM sodium dihydrogen phosphate, 300 mM sodium chloride, 20 mM imidazole, pH 8.0), mix them evenly, and flow through them with 2 mL of Binding / wash buffer in advance. Buffer equilibrated column prepacked with 1mL Ni-IDA resin;

[0038] Then wash the column with 2mL Binding / wash buffer; then, elute with 2mL Elution Buffer (50mM sodium dihydrogen phosphate, 300mM sodium chloride, 500mM imidazole, pH=8.0), collect the eluate to obtain the corresponding purified enzyme liquid.

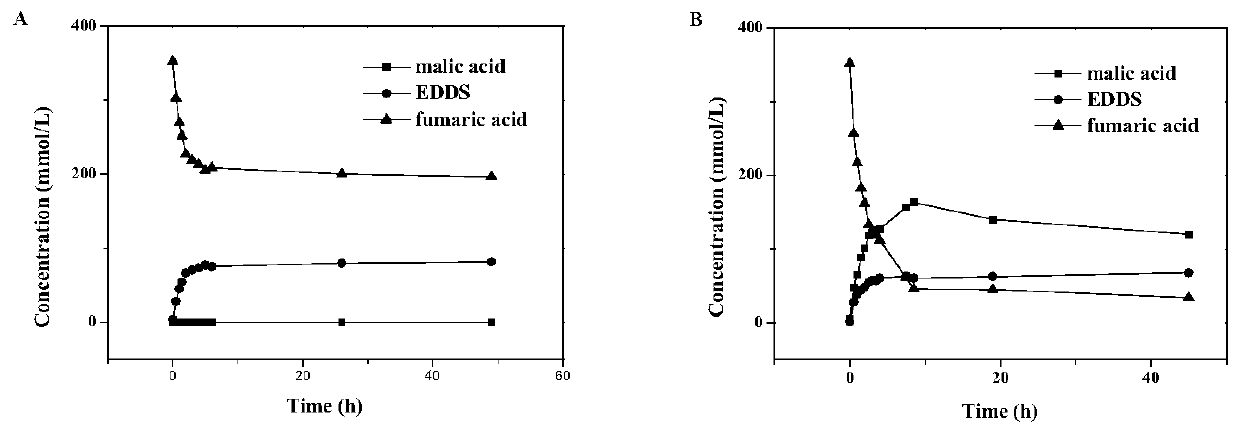

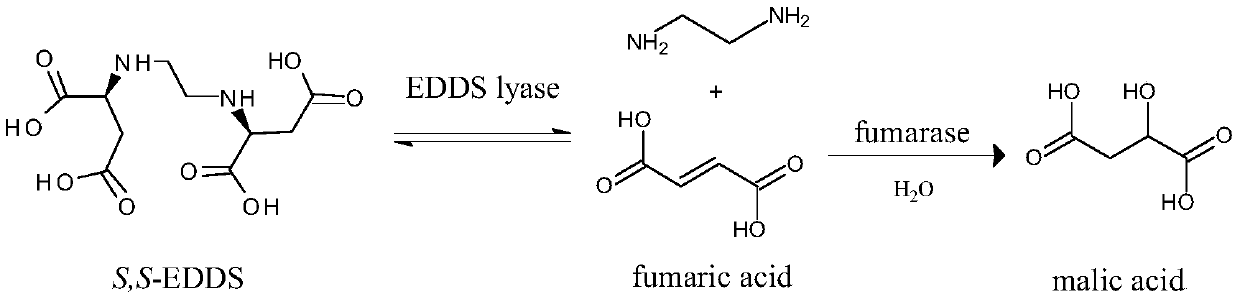

[0039] The standard EDDS lyase activity detection method for the above-mentioned purified enzyme solution can be used as follows: take 500uL enzyme solution, add 1.0mL reaction substrate solution (50mmol / L tris, 50mmol / L sodium dihydrogen phosphate; 600mmol / L fumaric acid; 300mmol / L ethylenediamine hydrochloride; pH8.0), the temperature is controlled at 30°C, the rotation speed...

Embodiment 3

[0044] Take 20g of LX-1000HA resin, wash with 100mL of deionized water and 100mL of 100mmol / L sodium phosphate buffer solution with a pH of 8.0, filter and dry, then add 100mL of 100mmol / L with a pH of 8.0 containing 2.0wt% glutaraldehyde Sodium phosphate buffer solution, the temperature was controlled at 30° C., and the rotation speed was 200 rpm for 2 hours, the resin was recovered, washed 3 times with deionized water, and the activated LX-1000HA resin carrier was obtained.

[0045] Take 20ml of the purified enzyme liquid obtained by the method of Example 2 above, add 1.0g of glutaraldehyde-activated amino carrier, control the temperature at 30°C, and carry out immobilization treatment at 200rpm for 1 hour. During the fixation process, take 20uL of the clear liquid and add 80uL Coomassie Brilliant Blue solution (25mg G250, 12.5mL ethanol, 25mL 85% phosphoric acid, after dissolving, add deionized water to 250mL) to detect protein residues, and control residues by gradually inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com