High-efficiency bimetallic nickel molybdenum selenide electro-catalytic material and preparation method thereof

A metal nickel-molybdenum, selenide electro-technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of small number of active sites, insufficient performance of transition metal molybdenum diselenide, stable problems such as poor performance, to achieve the effect of efficient catalysis, improved catalytic performance, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of a kind of high-efficiency bimetallic nickel-molybdenum-selenide electrocatalytic material proposed by the present invention comprises steps:

[0037] S1. Preparation of nickel-molybdenum mixed solution: according to the molar ratio of nickel to molybdenum of 1-3:1-3, nickel source and molybdenum source are added to the solvent containing surfactant, and after stirring and mixing, the obtained Said nickel-molybdenum mixture;

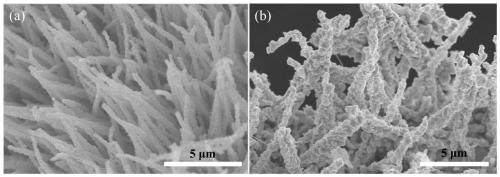

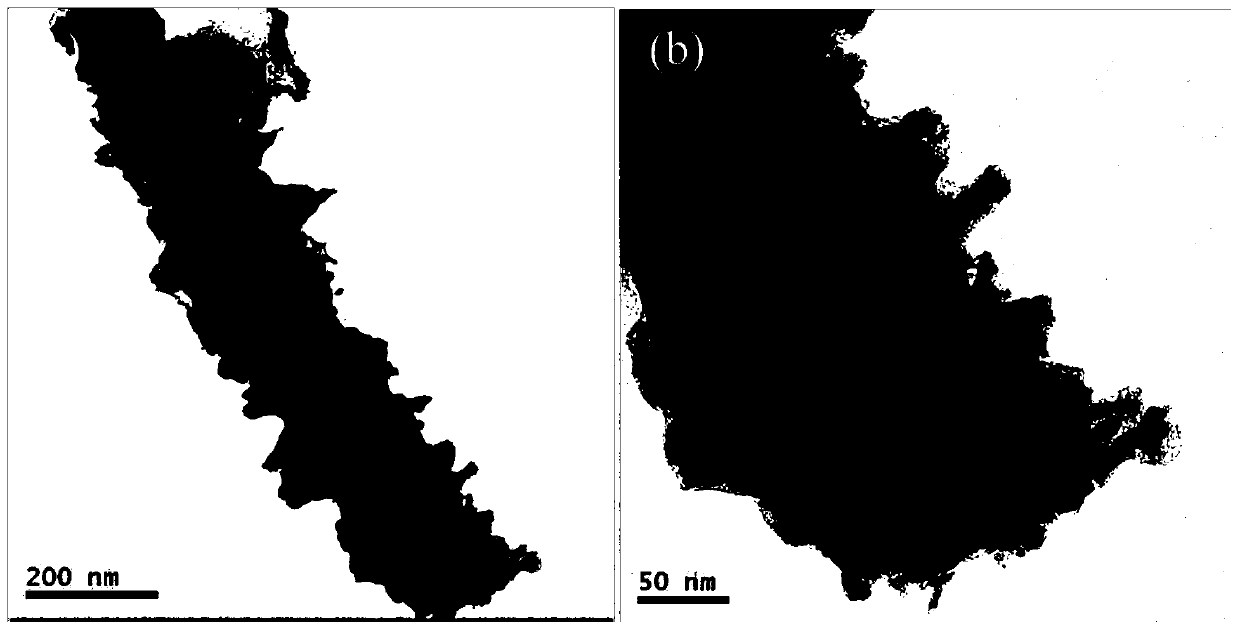

[0038]S2. Preparation of nanowire precursor: transfer the nickel-molybdenum mixture into a reaction vessel filled with nickel foam (Nickel foam, NF) for solvothermal treatment, take out the nickel foam and vacuum-dry it to obtain in-situ growth the nanowire precursor;

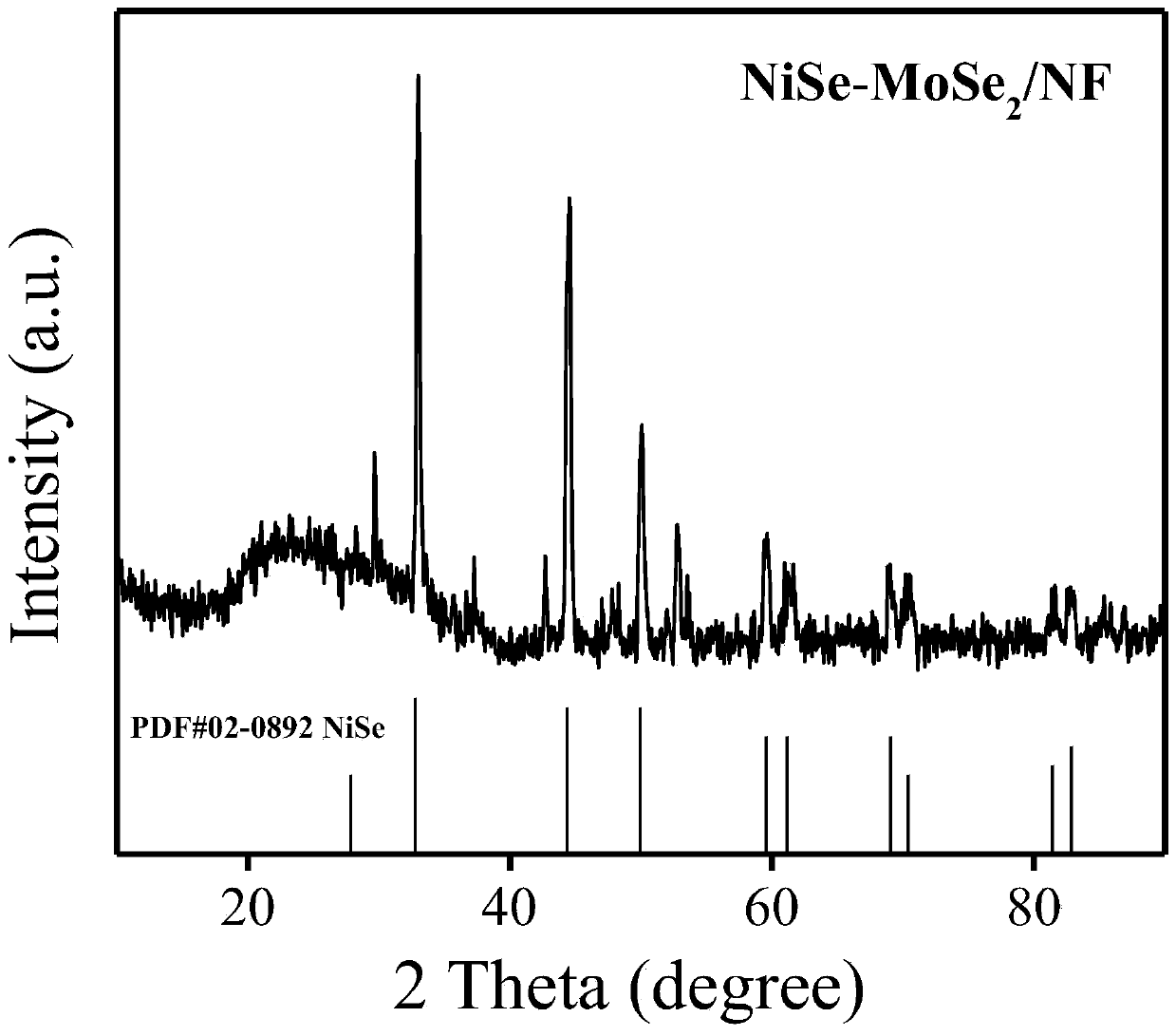

[0039] S3, primary calcination: the nanowire precursor is covered with selenium powder, and the first calcination is carried out at 300-500°C in an argon-hydrogen mixed atmosphere to obtain a nickel-molybdenum bimetallic selenide material Ni with a nickel ...

Embodiment 1

[0064] S1, Preparation of nickel-molybdenum mixed solution: Preparation of nickel-molybdenum mixed solution: Take 81.4mg nickel nitrate hexahydrate, 74.1mg ammonium molybdate tetrahydrate (molar ratio Ni:Mo=2:3) and 65mg CTAB dissolved in 30mL solvent B In the aqueous glycol solution, the nickel-molybdenum mixed solution is obtained after magnetic stirring for half an hour;

[0065] S2, preparation of nanowire precursor: transfer the nickel-molybdenum mixture into a clean container with an area of 1x3cm 2 In the reaction kettle (50mL) of foamed nickel, put the reaction kettle into an oven, heat it at 160°C for 6 hours and carry out solvent heat treatment, take out the foamed nickel and rinse it several times with ethanol aqueous solution, then put it into a vacuum oven, and heat it at 60 After vacuum drying for 3 hours at °C, the nanowire precursor grown in situ on nickel foam (NF) was obtained;

[0066] S3, calcining: cutting the nanowire precursor into 0.5x1.5 cm 2 The s...

Embodiment 2

[0069] A kind of nickel molybdenum double metal selenide catalytic material Ni of the present invention 0.85 Se-MoSe 2 The preparation method of / NF comprises the steps:

[0070] S1, Preparation of nickel-molybdenum mixed solution: Preparation of nickel-molybdenum mixed solution: Take 81.4mg nickel nitrate hexahydrate, 74.1mg ammonium molybdate tetrahydrate (molar ratio Ni:Mo=2:3) and 65mg CTAB dissolved in 30mL solvent B In the aqueous glycol solution, the nickel-molybdenum mixed solution is obtained after magnetic stirring for half an hour;

[0071] S2, preparation of nanowire precursor: transfer the nickel-molybdenum mixture into a clean container with an area of 1x3cm 2 In the reaction kettle (50mL) of foamed nickel, put the reaction kettle into an oven, heat it at 180°C for 6 hours and carry out solvent heat treatment, take out the foamed nickel and rinse it several times with ethanol aqueous solution, then put it into a vacuum oven, and heat it at 60 The nanowire pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com