Environment-friendly water-resistant reinforced latex for paper as well as preparation method and application thereof

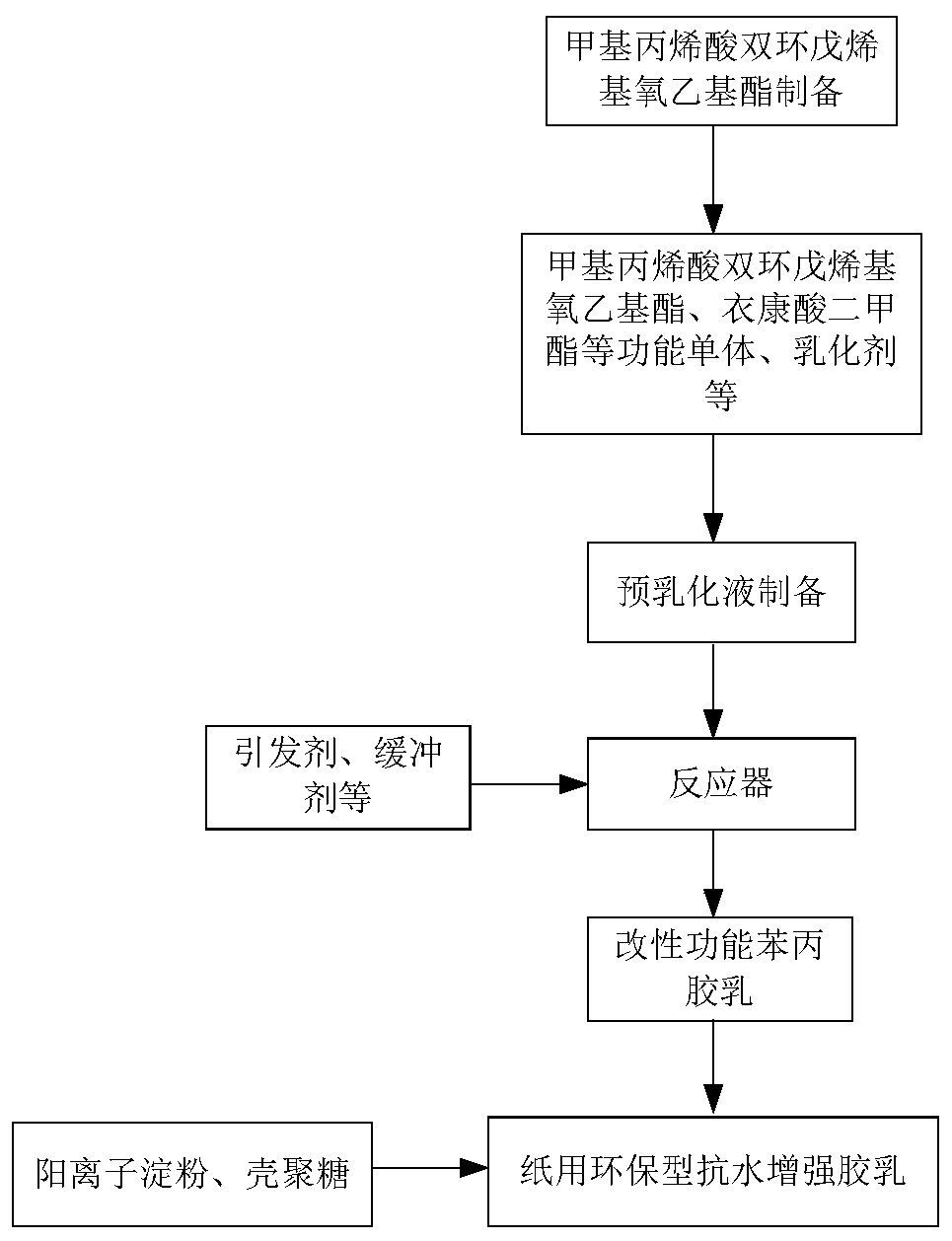

An environmentally friendly, reinforced glue technology, applied in paper, papermaking, paper coating, etc., can solve the problems of paper straw stiffness, water resistance, heat resistance, poor printing suitability, and difficulty in satisfying consumers, so as to reduce bacterial pollution , Improve rigidity, improve gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of a kind of environment-friendly water-resistant reinforced latex for paper of this embodiment is obtained by the following method:

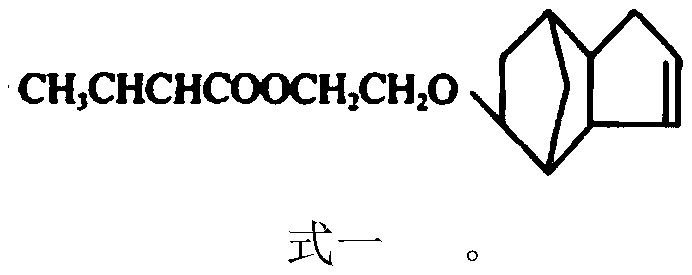

[0048] (1) Preparation of Dicyclopentenyl Oxyethyl Methacrylate

[0049] (a) According to the ratio, add ethylene glycol and dicyclopentadiene to the reactor 2 in sequence, then continue to slowly add p-toluenesulfonic acid, stir the obtained reaction solution evenly, and then gradually raise the temperature of the reaction system to 116°C , keep warm for 3h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; wherein: the ethylene glycol, dicyclopenta The mass ratio of diene, p-toluenesulfonic acid and sodium carbonate is 1:1.9:0.0012:0.0017.

[0050] (b) in reactor 3, add successively the mixture 1 that is formed by the ethylene glycol biscyclopentenyl et...

Embodiment 2

[0059] The preparation method of a kind of environment-friendly water-resistant reinforced latex for paper of this embodiment is obtained by the following method:

[0060] (1) Preparation of Dicyclopentenyl Oxyethyl Methacrylate

[0061] (a) According to the ratio, add ethylene glycol and dicyclopentadiene in the reactor 2 in sequence, then continue to slowly add p-toluenesulfonic acid, stir the obtained reaction solution evenly, and then gradually raise the temperature of the reaction system to 115°C , keep warm for 3.5h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; wherein: the ethylene glycol, bicyclic The mass ratio of pentadiene, p-toluenesulfonic acid and sodium carbonate is 1:1.9:0.0012:0.0017.

[0062] (b) in reactor 3, add successively the mixture 1 that is formed by the ethylene glycol biscyclopentenyl...

Embodiment 3

[0071] The preparation method of a kind of environment-friendly water-resistant reinforced latex for paper of this embodiment is obtained by the following method:

[0072] (1) Preparation of Dicyclopentenyl Oxyethyl Methacrylate

[0073] (a) According to the ratio, add ethylene glycol and dicyclopentadiene to the reactor 2 in sequence, then continue to slowly add p-toluenesulfonic acid, stir the obtained reaction solution evenly, and then gradually raise the temperature of the reaction system to 120°C , keep warm for 2.5h, after the reaction is over, cool to room temperature; finally add sodium carbonate aqueous solution, wash with distilled water, and rectify under reduced pressure to obtain ethylene glycol dicyclopentenyl ether; wherein: the ethylene glycol, bicyclic The mass ratio of pentadiene, p-toluenesulfonic acid and sodium carbonate is 1:1.9:0.0012:0.0017.

[0074] (b) in reactor 3, add successively the mixture 1 that is formed by the ethylene glycol biscyclopentenyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com