Method for preparing novel nodular cast iron railway turnout accessory

A technology for ductile iron and railways, applied in casting molding equipment, casting molds, cores, etc., can solve the problems of poor antifreeze and fracture resistance, and achieve the effects of avoiding molten iron splashing, improving corrosion resistance, and reducing slag inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

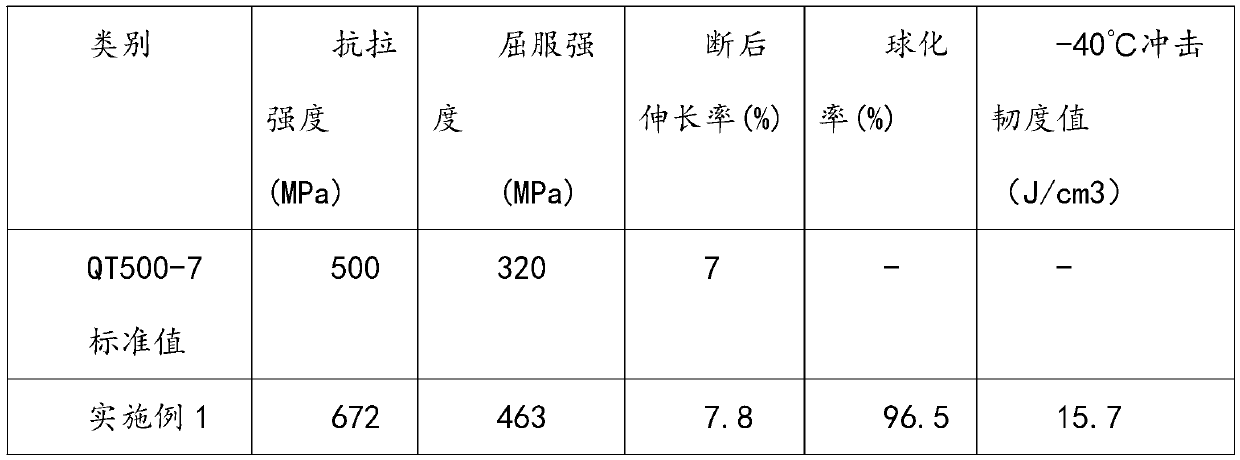

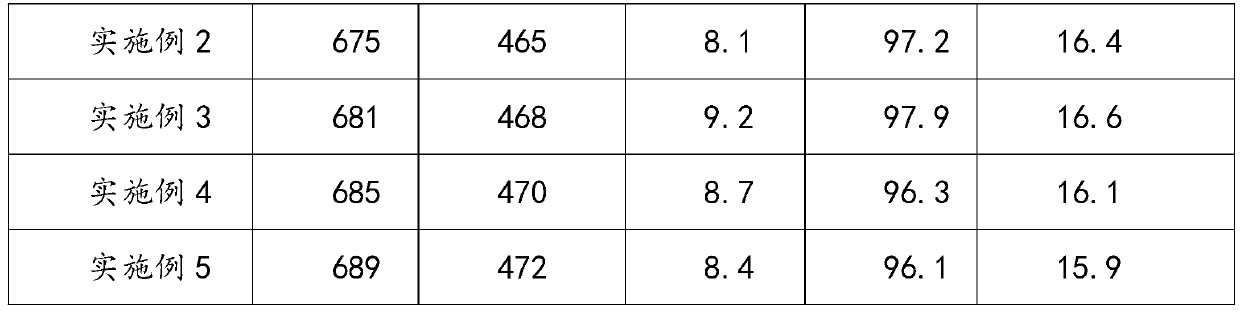

Examples

preparation example Construction

[0023] The invention provides a method for preparing a novel ductile iron railway turnout fitting, wherein the mass percentages of elements in the novel ductile iron railway turnout fitting are: carbon 4.3%-4.7%, silicon 2.3%-2.5%, nickel 0.5% -0.7%, aluminum 0.01%-0.06%, magnesium 0.02%-0.03%, manganese≤0.2%, phosphorus≤0.02%, sulfur≤0.01%, and the balance is iron.

[0024] Among them, the carbon equivalent is controlled at 4.3%-4.7%, and its content is increased compared with the conventional preparation method. By properly increasing the carbon equivalent, the fluidity of molten iron can be increased, which is beneficial to casting and feeding, and it is also useful to use molten iron Ferrite is formed, and at the same time, it is beneficial to the decomposition of cementite and pearlite in the matrix structure during the annealing process, so as to obtain more ferrite matrix structure, thereby improving the low-temperature impact resistance and plasticity of the new ductile...

Embodiment 1

[0035] A method for preparing a novel ductile iron railway turnout fitting provided by the present invention, wherein the mass percentages of elements in the novel ductile iron railway turnout fitting are: 4.3% carbon, 2.3% silicon, 0.5% nickel, 0.01% aluminum, Magnesium 0.02%, manganese ≤ 0.2%, phosphorus ≤ 0.02%, sulfur ≤ 0.01%, the balance is iron;

[0036] Its preparation method specifically comprises the following steps:

[0037] Step 1: Add high-quality pig iron, scrap steel containing carbon steel components, nickel ingots and aluminum ingots into the intermediate frequency induction furnace. During the smelting process, the temperature of the molten iron is kept at 1450°C to obtain molten iron with qualified chemical composition;

[0038] Step 2: Add an inoculant of 0.3% of the total amount of molten iron into the spheroidizing ladle with slag collecting bags with filters installed on the upper end and the bottom, and use an intrusive spray gun to spray blunt into the sp...

Embodiment 2

[0045] The invention provides a method for preparing a novel ductile iron railway turnout fitting, wherein the mass percentages of elements in the novel ductile iron railway turnout fitting are: 4.4% carbon, 2.35% silicon, 0.55% nickel, 0.025% aluminum, Magnesium 0.023%, manganese ≤ 0.2%, phosphorus ≤ 0.02%, sulfur ≤ 0.01%, the balance is iron;

[0046] Its preparation method specifically comprises the following steps:

[0047] Step 1: Add high-quality pig iron, scrap steel containing carbon steel components, nickel ingots and aluminum ingots into the intermediate frequency induction furnace. During the smelting process, the temperature of the molten iron is kept at 1465°C to obtain molten iron with qualified chemical composition;

[0048] Step 2: Add an inoculant of 0.35% of the total amount of molten iron into the spheroidizing ladle with slag collecting bags with filters installed at the upper end and the bottom, and use an intrusive spray gun to spray blunt into the sphero...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com