Natural ester insulating oil adsorption treatment system and preparation method and application of natural ester insulating oil

A technology for adsorption treatment and insulating oil, which is applied in the direction of selective adsorption, ion exchange treatment devices, petroleum industry, etc. It can solve the problems that bound water is difficult to remove, and the insulation performance of natural ester insulating oil cannot be improved, so as to avoid quality degradation and good Water removal effect, stable property effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

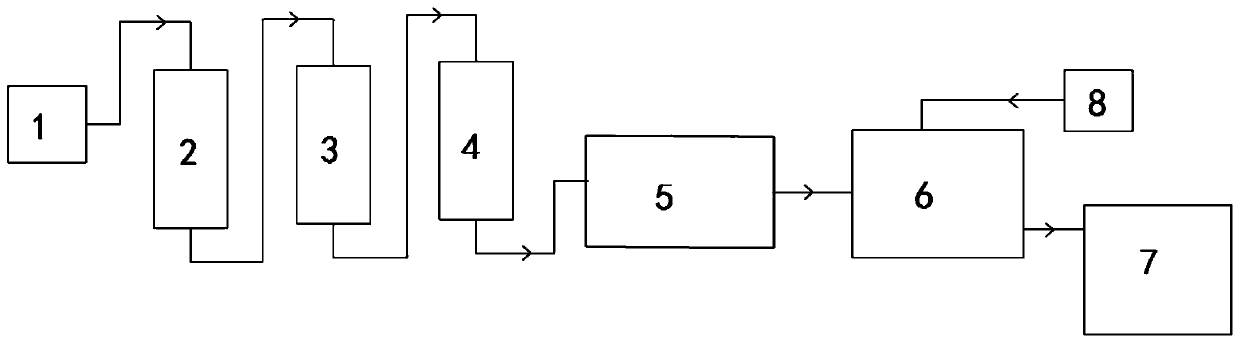

Image

Examples

preparation example Construction

[0042] In the third aspect, a method for preparing natural ester insulating oil, the specific steps are: firstly subject the vegetable oil to the above-mentioned adsorption treatment method, and then perform vacuum drying treatment.

[0043] The order of vacuum treatment and adsorption treatment cannot be reversed. A small amount of water in natural ester insulating oil can ensure that polar substances are fully adsorbed by the adsorbent. If it is dried first, the adsorption effect will be affected.

[0044] In some embodiments of the present invention, the vegetable oil is one or more of natural vegetable oils such as soybean oil, palm oil, sunflower oil, and rapeseed oil. The present invention can be applied to natural ester insulating oils derived from various vegetable oils.

[0045] In some embodiments of the present invention, the vacuum drying temperature is 30-60°C, the vacuum degree is 0.3-0.7MPa, and the drying time is 2-6h; preferably, the vacuum drying temperature ...

Embodiment 1

[0060] 1. After the refined quartz sand, ZSM-5 molecular sieve and β-alumina particles with a particle size distribution between 0.1-0.25cm are dried at 70°C for 10 hours, they are packed in the adsorption column respectively, and each adsorbent is packed tightly. , the packing layer height of each particle in the adsorption column is 50 cm, and the diameter is 5 cm. Commercially available food-grade soybean oil was selected as vegetable oil, and the flow route of soybean oil was quartz sand adsorption column-molecular sieve adsorption column-alumina adsorption column, the flow mode was natural downflow, and then collected for vacuum drying.

[0061] 2. Transfer the soybean oil treated by the adsorption process into a wide-mouth container, and the diameter / height of the wide-mouth container is >10:1, and carry out vacuum drying. The vacuum drying temperature is 45°C, the vacuum degree is 0.5MPa, and the drying time is 4h. The dried soybean oil is quickly sealed and stored. T...

Embodiment 2

[0067] 1. Adsorption process and drying process steps are the same as in Example 1.

[0068] 2. Choose commercially available food-grade palm oil.

[0069] 3. The processing and analysis process is the same as in Example 1, and the analysis data of palm insulating oil are shown in Table 2.

[0070] Table 2

[0071] index result index result acid value 0.02mg / g pour point -20.5℃ water content 71.7mg / kg volume resistivity 1.8*10 10

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com