Oleaginous yeast and application thereof

A technology of oleaginous yeast and yeast, which is applied in the field of microorganisms, can solve the problems of long fermentation period, low utilization rate of cellulose resources, and high production cost, and achieve the effects of low cost, improved sugar utilization efficiency and production intensity, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of bagasse hydrolyzate:

[0034] (1) Alkali Catalyzed Atmospheric Pressure Glycerin Organic Solvent Pretreatment of Bagasse

[0035]Weigh 100 g of dried bagasse and put it into a 5000 mL three-neck flask, then add 1000 g of glycerol and 0.2% (w / w) NaOH solid. Put the three-neck flask containing the matrix into a constant temperature heating mantle, and at the same time mechanically stir to mix the matrix evenly and keep it at 240°C for 10min. After the reaction, pour 1500mL tap water into the flask to fully dissociate the matrix, then filter with a G1 sand core funnel, then wash the filter cake twice with 2000mL tap water and suction-filter, the final filter cake obtained is the bagasse matrix. Divide the matrix into two parts, one part is air-dried to 50% water content and stored at 4°C; the other part is oven-dried at 105°C to absolute weight.

[0036] (2) Enzymatic hydrolysis of matrix after pretreatment

[0037] Weigh 16g of matrix with a water conten...

Embodiment 1

[0040] Embodiment 1: mutation and screening of bacterial strain

[0041] (1) Preparation of bacterial suspension: after activation of the preserved wild oleaginous yeast strain, pick a single colony in YPD seed medium, culture at 25°C, 140r / min for 36h, take 1mL of the bacterial liquid and centrifuge at 8000r for 5min to collect the bacteria , washed three times with sterile normal saline, mixed on a vortex instrument to disperse the bacteria, and adjusted the concentration of the bacteria suspension to OD 600 =1 bacterial suspension, for subsequent use;

[0042] (2) ARTP mutagenesis: take 10ul wild oleaginous yeast ZZ-46 bacterial suspension in the ultra-clean workbench and spread it on a sterile metal slide, and place the metal slide in the groove of the stage in the operating room of the ARTP mutagenesis instrument Inside, nitrogen is used as the working gas, the set power is 100W, the processing distance is 2mm, the gas flow rate is 10L / min, and the processing time is 140...

Embodiment 2

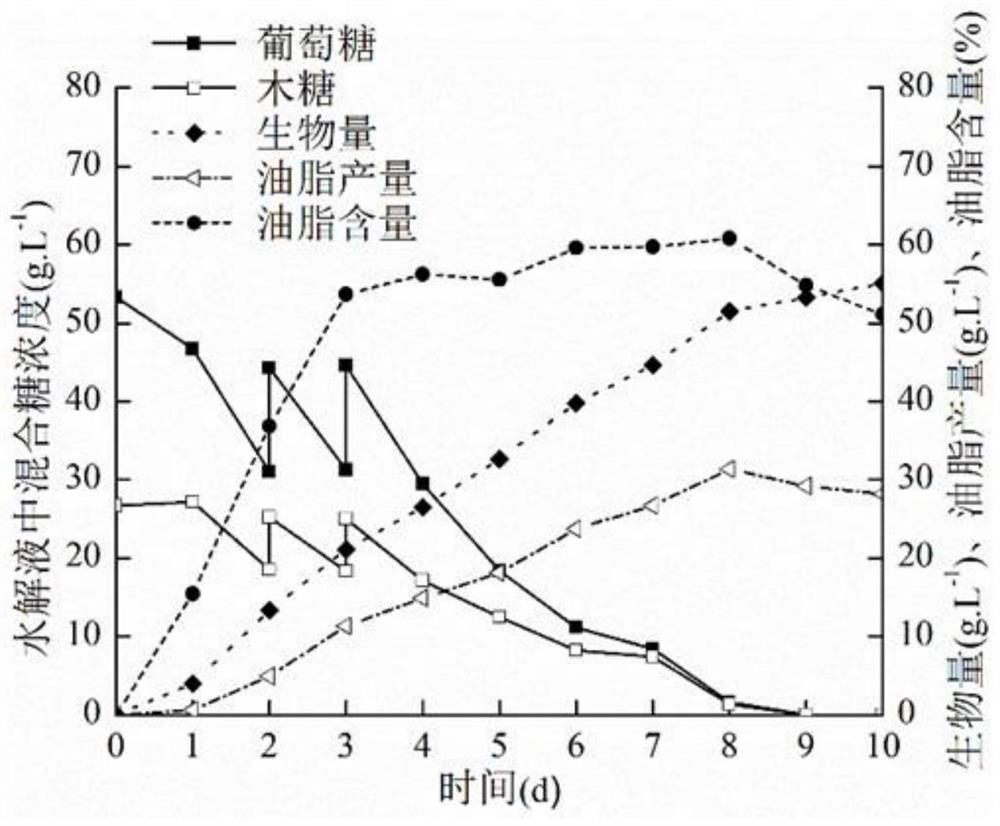

[0054] Embodiment 2: utilize bagasse hydrolyzate to ferment

[0055] Bagasse hydrolyzate fermentation medium components: bagasse hydrolyzate diluted to 70g / L of total sugar, pH adjusted to 6, no other nitrogen sources, inorganic salts and other substances added.

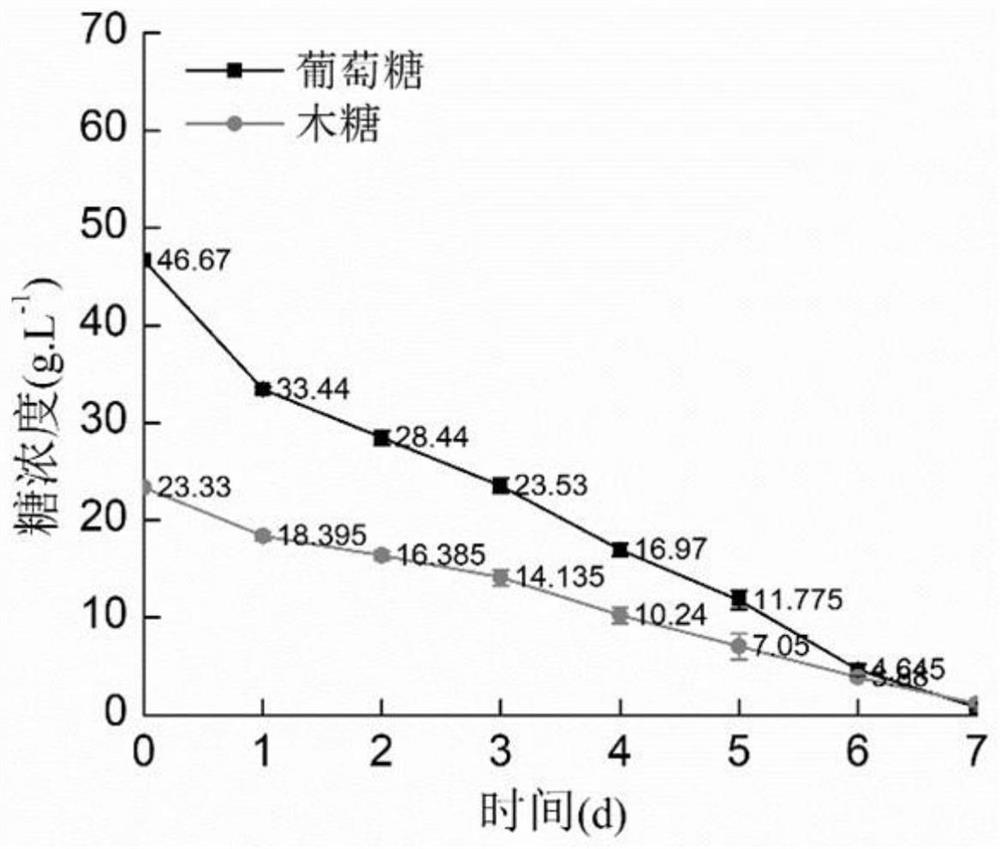

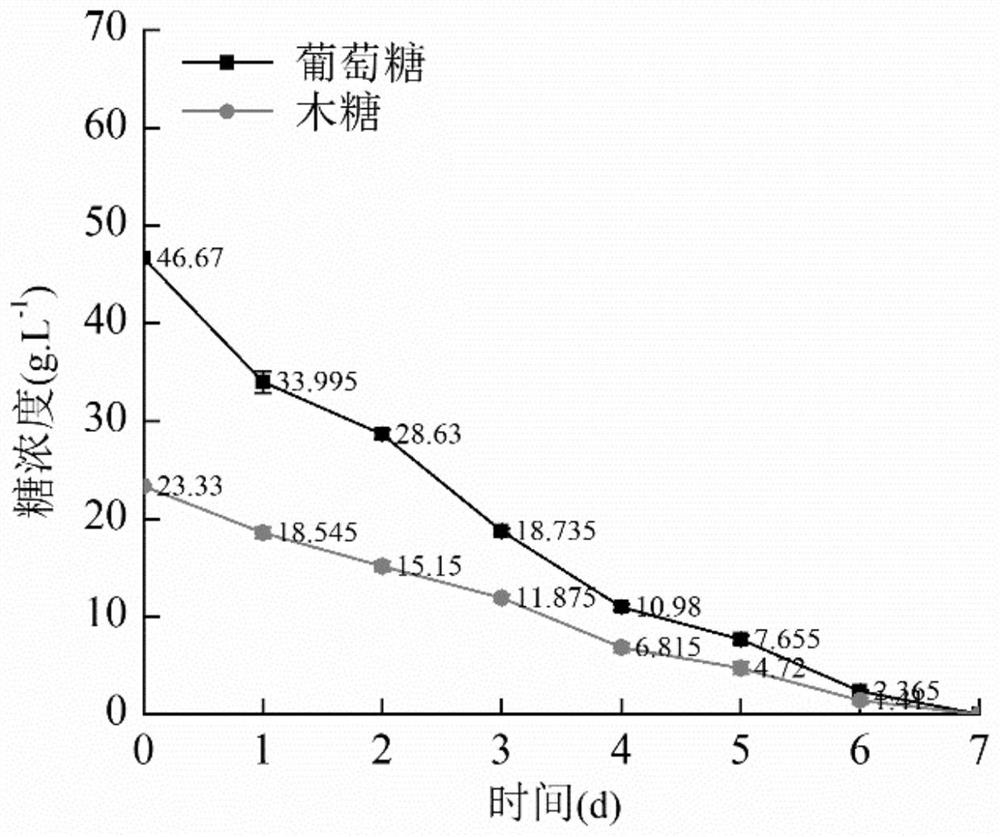

[0056] Fermentation of bagasse hydrolyzate: inoculate a single colony of strain L7 in YPD seed medium, culture at 25°C, 140r / min for 36h, until OD 600 7.6, then inoculate 50 / 250mL according to 10% inoculum size (that is, 50mL fermentation medium in a 250mL Erlenmeyer flask) bagasse hydrolyzate medium, 140r / min, 25 ℃ of fermentation for 7 days.

[0057] Oil production by strain fermentation: ferment strain L7 in bagasse hydrolyzate fermentation medium, its biomass, oil yield and oil content are 18.87g / L, 18.87g / L, 9.26g / L and 49.07%, and the starting strain ZZ-46 was 15.21g / L, 6.76g / L and 44.46%, among which the biomass and oil production increased by 24.06% and 36.98% respectively compared with the starting strain. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com