Genetically engineered bacterium for expressing insulin precursor, and preparation method and application of genetically engineered bacterium

A technology of insulin precursors and genetically engineered bacteria, applied in genetic engineering, insulin, botany equipment and methods, etc., can solve the problems of expensive culture medium, easy introduction of animal-derived viruses, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

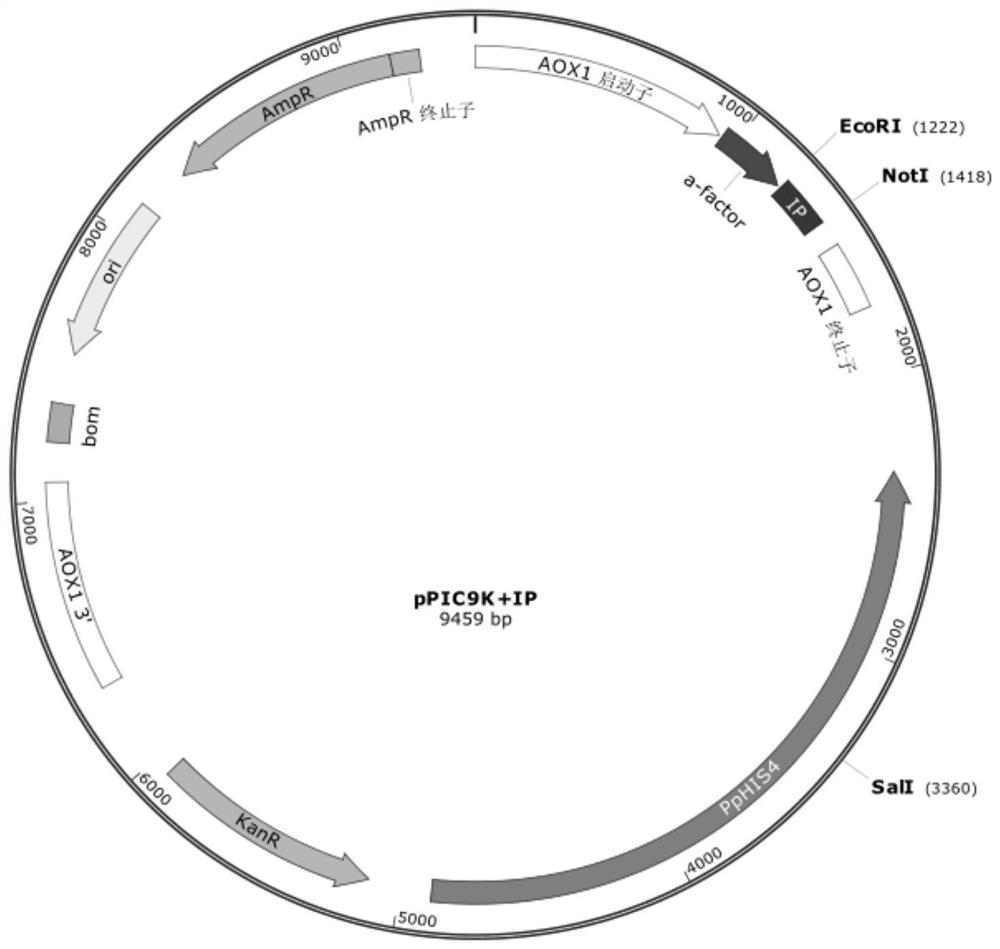

[0046] Example 1: Expression vector pPIC9K-IP (IP is insulin precursor, insulin precursor, and the plasmid map is as follows figure 1 shown) and the construction and screening of Pichia pastoris engineering bacteria

[0047] The invention adopts pPIC9K vector, the cloning sites are EcoR I and Not I, and the recombinant vector is pPIC9K-IP. The expression vector is transcribed from the AOX1 promoter.

[0048] The target gene fragment (the specific sequence of the gene sequence such as SEQ ID NO.1) was synthesized by the company (Shanghai Ruidi Biotechnology Co., Ltd.) and cloned on the pPIC9K vector (purchased from Invitrogen), and the cloning sites were EcoR I and NotI , the plasmid pPIC9K-IP was obtained.

[0049] 2. Extract the plasmid pPIC9K-IP obtained above, and use the following enzyme digestion system to perform plasmid linearization enzyme digestion reaction:

[0050]

[0051] Digest at 37°C for 4 hours, place the digested product at 70°C, and inactivate the rest...

Embodiment 2

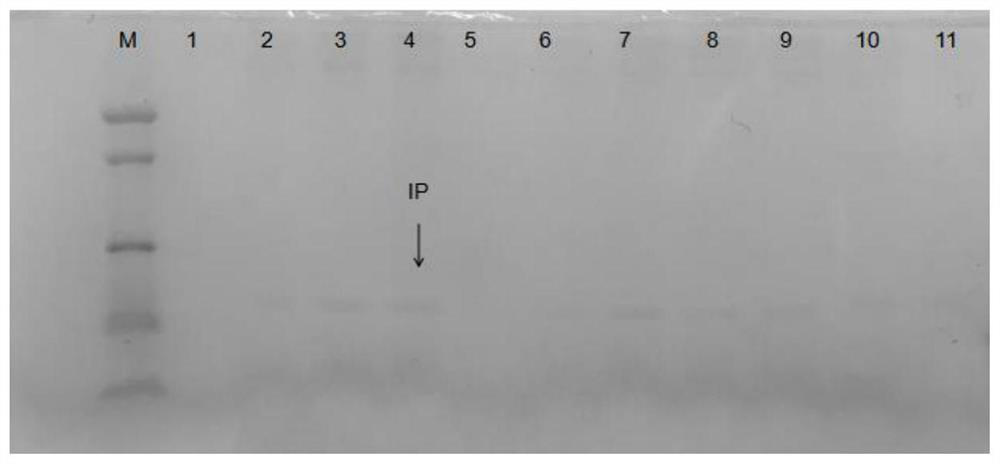

[0063] Embodiment 2: Shake flask horizontal culture fermentation

[0064] Randomly pick the transformant in the MD plate of the third part in Example 1 and the YPD plate containing 5, 6, and 7 mg / mL G418 in the fourth part of Example 1 and transfer it to a test tube containing 2 mL of YPD liquid medium Cultivate YPD bacteria liquid at 28°C and 230rpm; transfer the obtained YPD bacteria liquid to contain 6mL BMGY (composed of: 10g / L yeast extract, 20g / L tryptone, 3.4g / LYNB, 100mM potassium phosphate buffer, 400μg / L biotin, 10g / L glycerol) in a 20mL shake flask for about 18 hours, and the shake flask was placed in a refrigerator at 4°C for free sedimentation for 6 hours; the supernatant in the shake flask was poured out carefully, and 20mL BMMY (composed of : 10g / L yeast extract, 20g / L tryptone, 3.4g / L YNB, 100mM potassium phosphate buffer, 400μg / L biotin, 0.5% methanol [% is the volume ratio of the whole culture medium]) continue to cultivate , adding 0.5% methanol in the med...

Embodiment 3

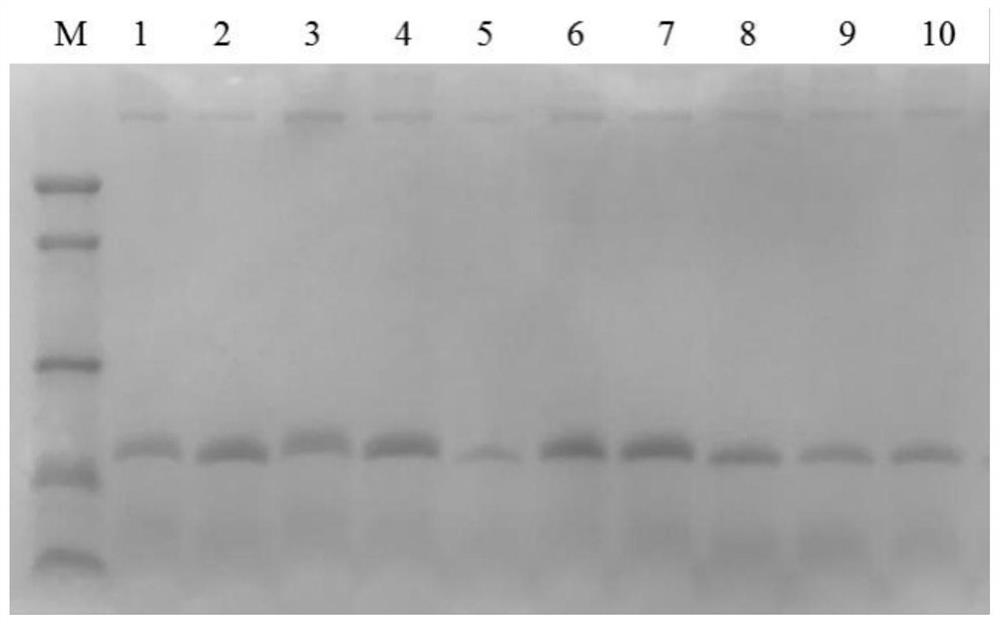

[0067] Example 3: 5L fermenter horizontal high-density fermentation

[0068] Inoculate the above-mentioned activated glycerol bacteria into a total of 6 tubes containing 2mL of YPD liquid medium, which is the primary seed solution;

[0069] Select 2 tubes of the first-grade seed liquid, a total of 4mL, and inoculate it in a 500mL shake flask containing 100mL of YPD liquid medium, and cultivate it at 28°C and 230rpm for 12 hours. seed liquid;

[0070]Configure BSM (40g / L glycerin, 26.7mL / L phosphoric acid (85%), 0.93g / L calcium sulfate dihydrate, 18.2g / L potassium sulfate, 14.9g / L magnesium sulfate heptahydrate, 4.13g / L potassium hydroxide , 4.0mL / L PTM1 (Pichia pastoris trace element 1 related components: 6g / L copper sulfate pentahydrate, 0.08g / L sodium iodide, 3g / L manganese sulfate monohydrate, 0.2g / L dihydrate and molybdic acid Sodium, 0.02g / L boric acid, 0.5g / L cobalt chloride, 20g / L zinc chloride, 65g / L ferrous sulfate heptahydrate, 0.2g / L biotin, 5mL / L sulfuric acid)),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com