Preparation method of silk fibroin tissue engineering scaffold based on near-field electrospinning technology

A tissue engineering scaffold and silk fibroin technology, applied in the field of preparation of silk fibroin tissue engineering scaffolds, can solve the problems that porogens are difficult to completely remove, reduce biomolecular activity, and high porosity of scaffolds, and achieve biocompatibility and high porosity. The effect of good biological activity, high production efficiency and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

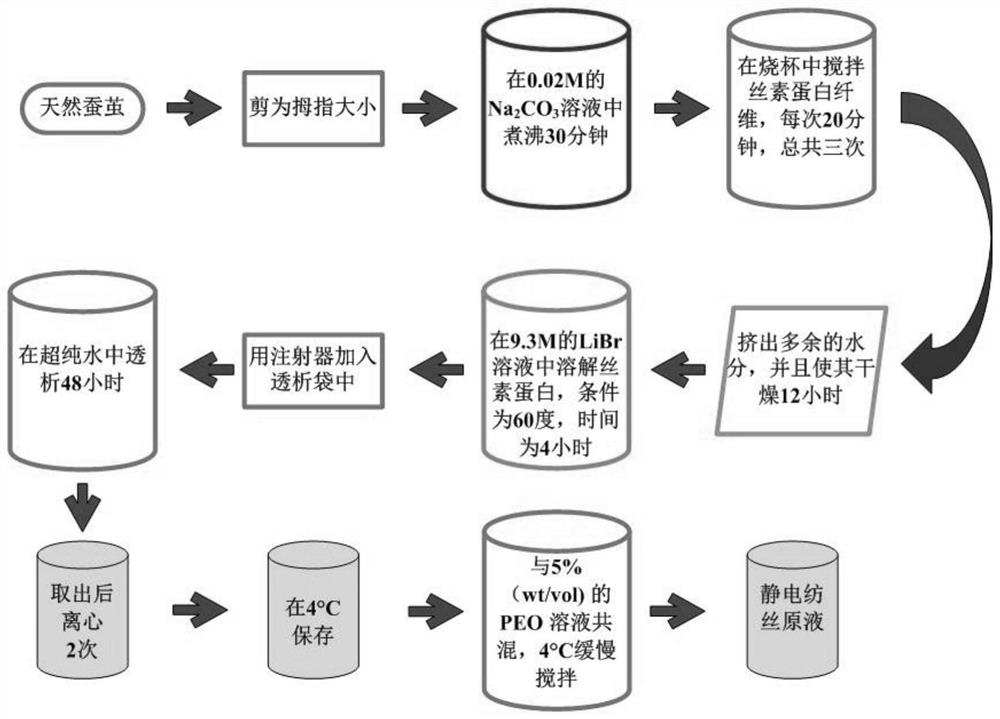

[0030] A silk fibroin tissue engineering scaffold is specifically prepared according to the following steps:

[0031] a. Preparation of silk fibroin aqueous solution: first prepare 2 liters of sodium carbonate solution with a substance concentration of 0.02mol / L, cut 5 grams of silkworm cocoons into pieces, cut them to the size of a coin, and put in a substance concentration of 0.02mol / L Boil in L of sodium carbonate solution for 30 minutes to remove sericin on the surface of silkworm cocoons, take it out, squeeze dry, rinse with ultrapure water for 2 to 3 times, put it in a beaker and stir it fully for 1 hour after rinsing, and change the water 3 times during the rinse , then placed in a fume hood and air-dried at room temperature to obtain silk fibroin fibers. According to the quality of air-dried silk fibroin fibers, the concentration of the prepared substance was a lithium bromide solution of 9.3mol / L, and the prepared lithium bromide solution was poured into the air-dried ...

Embodiment 2

[0037] A silk fibroin tissue engineering scaffold is specifically prepared according to the following steps:

[0038] a. Preparation of silk fibroin aqueous solution: first prepare 2 liters of sodium carbonate solution with a substance concentration of 0.02mol / L, cut 5 grams of silkworm cocoons into pieces, cut them to the size of a coin, and put in a substance concentration of 0.02mol / L Boil in L of sodium carbonate solution for 30 minutes to remove sericin on the surface of silkworm cocoons, take it out, squeeze dry, rinse with ultrapure water for 2 to 3 times, put it in a beaker and stir it fully for 1 hour after rinsing, and change the water 3 times during the rinse , then placed in a fume hood and air-dried at room temperature to obtain silk fibroin fibers, according to the quality of the air-dried silk fibroin fibers, the amount concentration of the preparation substance was a lithium bromide solution of 9.3mol / L, and the prepared lithium bromide solution was poured into ...

Embodiment 3

[0044] A silk fibroin tissue engineering scaffold is specifically prepared according to the following steps:

[0045] a. Preparation of silk fibroin aqueous solution: first prepare 2 liters of sodium carbonate solution with a substance concentration of 0.02mol / L, cut 5 grams of silkworm cocoons into pieces, cut them to the size of a coin, and put in a substance concentration of 0.02mol / L Boil in L of sodium carbonate solution for 30 minutes to remove sericin on the surface of silkworm cocoons, take it out, squeeze dry, rinse with ultrapure water for 2 to 3 times, put it in a beaker and stir it fully for 1 hour after rinsing, and change the water 3 times during the rinse , then placed in a fume hood and air-dried at room temperature to obtain silk fibroin fibers, according to the quality of the air-dried silk fibroin fibers, the amount concentration of the preparation substance was a lithium bromide solution of 9.3mol / L, and the prepared lithium bromide solution was poured into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com