pgs/sf electrospun artificial blood vessel and its preparation method

An artificial blood vessel and electrospinning technology, applied in the directions of blood vessels, electrospinning, and devices of human tubular structures, etc., can solve problems such as unknown performance, achieve good mechanical properties, achieve successful transplantation, and be easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) Synthesis of the PGS prepolymer: Take 0.1 mol sebacate and 0.1 mol glycerol to 250 ml of three-necked flask, placed in a magnetic stirrer and stir well, and vent the nitrogen gas at room temperature, oil bath heating, 125 ° C stirring After the heating reaction is 4h, the monomer is completely melted and uniformly mixed. The temperature was maintained at a nitrogen atmosphere to continue to rely at 48 h to give a PGS prepolymer. Cooling to room temperature is white waxy solid, 4-8 ° C preserve spare.

[0056] The PGS synthesis route is shown below, where n = 6-50:

[0057]

[0058] (2) Preparation of the SF film: 21.2 g of anhydrous sodium anhydrous sodium carbonate is dissolved in 10L has heated boiling deionized water, and then the 25g silkworm is removed from 30 min under the boiling conditions of 100 ° C, and then removed from the elimination Repeatedly wash five times and remove the residual silk glue. The silk is dried in an oven at 60 ° C to dryness to obtain p...

Embodiment 2

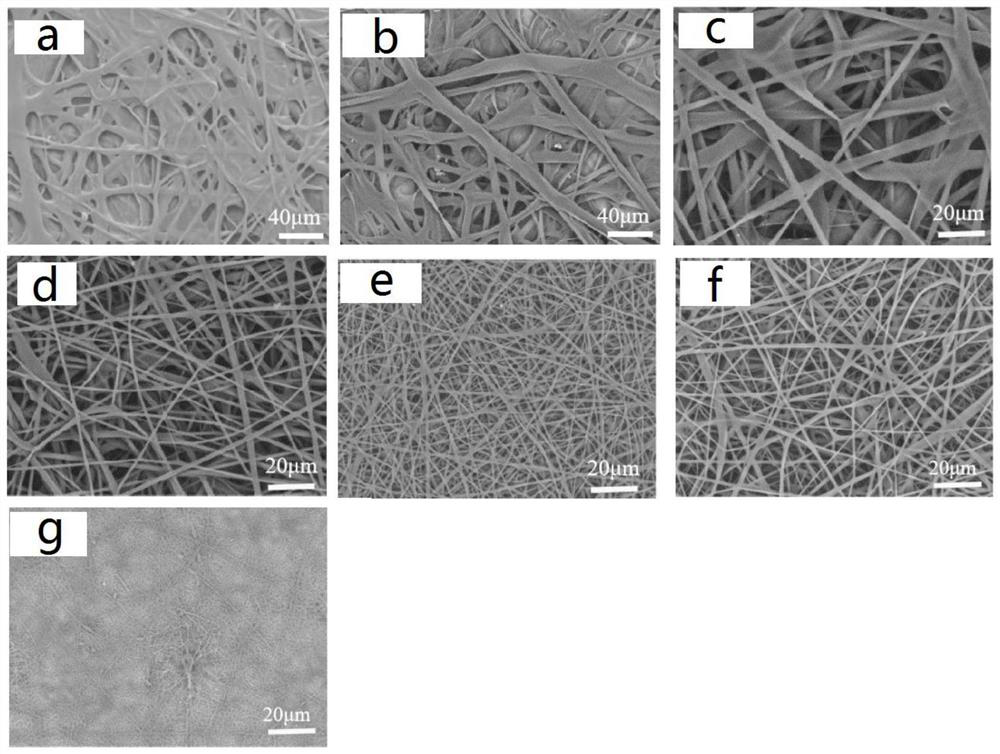

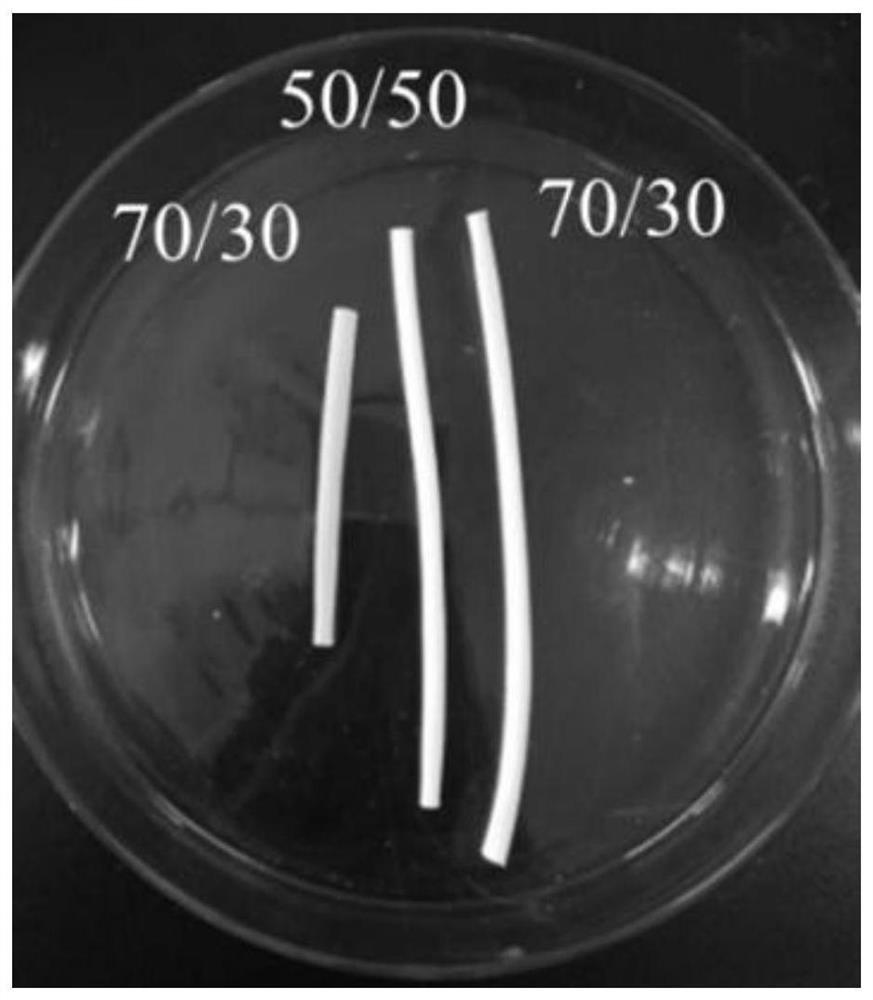

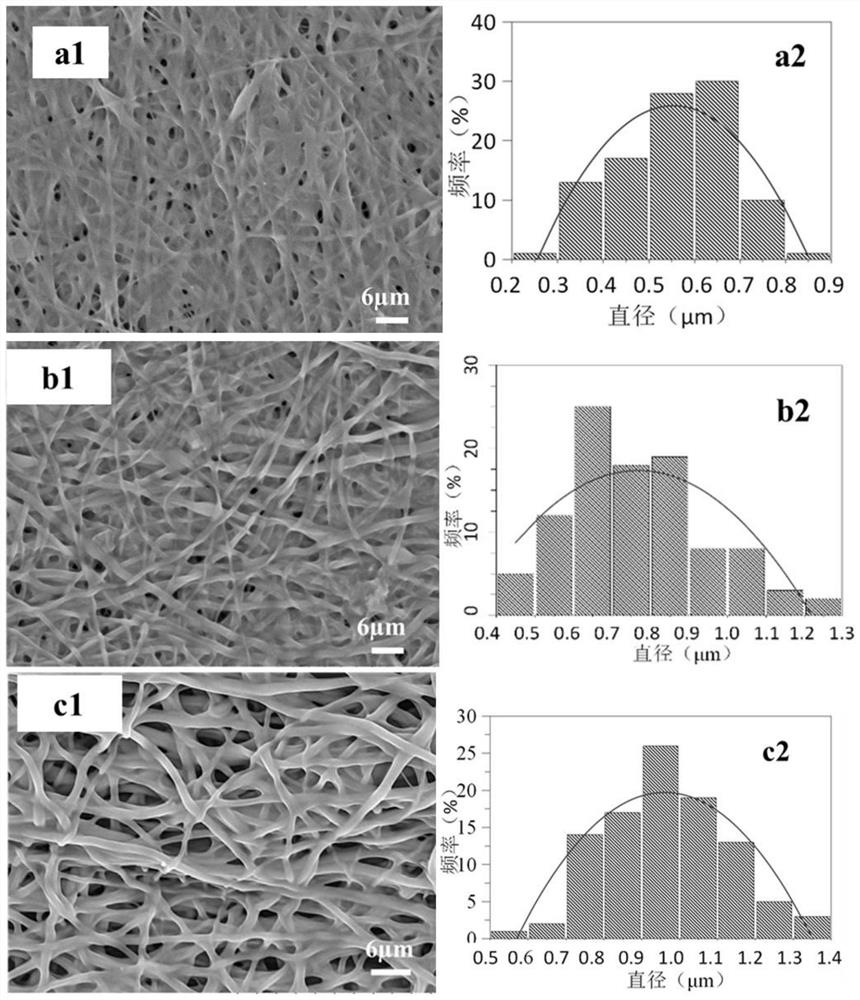

[0064] According to the method of the first step (1) - (2), the spinning liquid concentration is 9%, the mass ratio of the PGS and SF is selected from 70 / 30, 50 / 50, 30 / 70, and the artificial blood vessel is prepared in the step. 3) In the middle, the receiving device replaces a stainless steel roller having a diameter of 4 mm, and is prepared from the stainless steel to the stainless steel, and the PEO solution is pre-textured on the stainless steel roller, and the PEO spinning time is 3-5 min. The electrospinning parameters are set as follows: 12.5-15 kV of the voltage, 12cm reception distance, 2 ml / h, spinning time 1-1.5H, and speed 500R / min. The micro-nano-stage fibers generated during electrostatic spinning process wrapped around the receiving device forming a tubular PGS / SF electrospun film. After the spinning is completely immersed in the water receiving device to remove the PEO layer, The PGS / SF electrospin pipe can be smoothly released.

[0065] Since PGS has adjus...

Embodiment 3

[0079] According to the method of Example 2, the tubing was prepared by the mass ratio of PGS and SF as 70 / 30, 50 / 50, 30 / 70, and the difference was that 24 h was cured at 120, 125, 130, 135, 140 ° C. Such as Figure 10 The tensile properties shown in each mass ratio PGS / SF tubular material under different curing conditions. When the temperature is less than 130 ° C, the mechanical properties of the PGS / SF tubular material are poor, and the CGS curing rate is not high; when the curing temperature is increased to 130 ° C, the mechanical properties of the PGS / SF tubular material have a significant increase, and The curing temperature is again improved, and the breakage intensity and elongation elongation increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com