Method for continuously and quickly preparing propargyl alcohol by using micro-reactor

A micro-reactor, propargyl alcohol technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, preparation of hydroxyl compounds, etc., can solve the problems of harsh reaction conditions and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of method utilizing microreactor to prepare propargyl alcohol continuously and rapidly, its main steps are as follows:

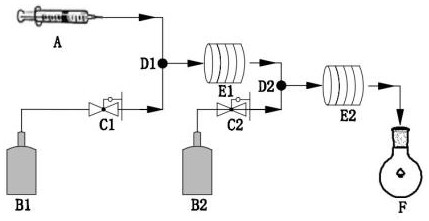

[0022] Under anhydrous and oxygen-free conditions, add 3.0 g metallic magnesium, 1.2 g elemental iodine and 20 mL anhydrous ether into the reactor, start stirring after the elemental iodine dissolves, and slowly add 5.0 mL ethyl bromide dropwise at a rate to maintain It is advisable for the liquid to boil, and after the dropwise addition, heat to 60 o C was refluxed for 60 min to obtain ethyl magnesium bromide; then as flow process figure 1 As shown, acetylmagnesium bromide and acetylene gas are respectively injected into the micro-mixer D1 (T-type tee, inner diameter: 0.021 mm) by the pump A and the gas controller C1 according to the molar ratio of 1:1.2. Microreactor E1 (inner diameter: 0.1 mm) at -20 o Under the condition of C, the reaction was carried out for 10 min, and the acetylene magnesium bromide was obtained through the Grignard e...

Embodiment 2

[0024] A kind of method utilizing microreactor to prepare propargyl alcohol continuously and rapidly, its main steps are as follows:

[0025] Under anhydrous and oxygen-free conditions, add 3.0 g metallic magnesium, 1.2 g elemental iodine and 20 mL anhydrous ether to the reactor. After the elemental iodine dissolves, start stirring and slowly add 5 mL vinyl iodide dropwise at a rate to maintain It is advisable for the liquid to boil, and after the dropwise addition, heat to 80 o C was refluxed for 120 min to obtain a mixed solution of vinylmagnesium iodide and ether; then, as shown in the figure, vinylmagnesium iodide and acetylene gas were respectively injected into micro-mixer D1 by pump A and gas controller C1 according to the molar ratio of 1:0.8 After mixing in the medium (T-type tee, inner diameter: 0.1 mm), it enters the microchannel reactor E1 (inner diameter: 1 mm), at 20 o Under the condition of C, it was reacted for 3 minutes, and ethynylmagnesium iodide was obtain...

Embodiment 3

[0027] A kind of method utilizing microreactor to prepare propargyl alcohol continuously and rapidly, its main steps are as follows:

[0028] Under anhydrous and oxygen-free conditions, add 3.0 g metal magnesium, 1.2 g elemental iodine and 20 mL tetrahydrofuran into the reactor, start stirring after the elemental iodine dissolves and slowly add 5 mL ethyl chloride dropwise at a rate to maintain the liquid It is advisable to boil, and after the dropwise addition, heat to 100 o C was refluxed for 180 min to obtain a mixed solution of ethyl magnesium chloride and ether; then, as shown in the figure, the ethyl magnesium chloride and acetylene gas were respectively injected into the micro-mixer D1 by the pump A and the gas controller C1 according to the molar ratio of 1:1.5 ( T-type tee, inner diameter: 10 mm) mixed in the microchannel reactor E1 (inner diameter: 10 mm), at 40 o Under the condition of C, the reaction was carried out for 60 s, and the ethynylmagnesium chloride was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com