Radiopaque efficient drug-loading embolic microsphere as well as preparation method and application thereof

A technology of microspheres and embolization, which is applied in the field of medical materials, can solve the problems of high rebound force and high hardness after compression deformation, affecting the conductivity and embolization effect of embolization materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0118] Typically, the preparation method comprises the following steps:

[0119] Synthesis of (Acetal) Derivatives of Alkenoic Acids

[0120] Add 0.5-1.5 parts of sodium hydroxide and 3-15 parts of purified water into a four-necked flask and stir to form a solution, then slowly add 1 part of aminoalkyl (acetal) at 5-20 ° C, stir evenly Slowly add 0.2-5 parts of alkyl alkenoyl chloride dropwise at -5-15°C, and continue stirring for 1-5 hours after the dropwise addition. Add saturated sodium chloride solution to the reacted solution to wash, extract with methyl tert-butyl ether, extract the extract after dehydration, filter, concentrate, and then purify by column chromatography to obtain the (acetal) aldehyde derivative of alkyl alkenoic acid .

[0121] The (acetal) derivatives of alkylenoic acid have 3-20 carbon atoms.

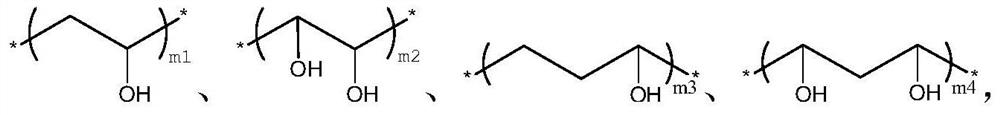

[0122] Synthesis of Functionalized Polyol Intermediates

[0123] Add 1 part of polyhydroxy polymer with a molecular weight of 5kDa-80kDa into a flask conta...

Embodiment 1

[0171] The synthesis of embodiment 1 N-acrylamido diethyl acetal

[0172]

[0173]Add 60g of sodium hydroxide and 600mL of purified water into a four-neck flask, stir to dissolve the sodium hydroxide completely, add 100g of aminoacetaldehyde diethyl acetal to it at 10°C, stir evenly, and cool down to -10°C in an ice-salt bath , slowly add 75g of acryloyl chloride dropwise and keep it warm for 2 hours; add 300mL of saturated sodium chloride solution to the reacted solution, stir and wash, then extract with 200mL of methyl tert-butyl ether for 3 times, and use 200g of anhydrous sodium sulfate for the extract After drying and dehydrating for 3 hours, it was filtered, and the filtrate was concentrated by rotary evaporation with a rotary evaporator until no liquid dripped out from the condenser tube of the evaporator. The obtained crude product was purified by column chromatography to obtain N-acrylamidodiethyl acetal.

Embodiment 2

[0174] Example 2 Synthesis of 4-acrylamide butyraldehyde dimethyl acetal

[0175]

[0176] Add 80g of sodium hydroxide and 800mL of purified water into a four-neck flask, stir to dissolve the sodium hydroxide completely, add 134.5g of 4-aminobutyraldehyde dimethyl acetal to it at 15°C, stir evenly, and cool down in an ice-salt bath to 5°C, slowly add 100.5g of acryloyl chloride dropwise and keep it warm for 2 hours; add 400mL of saturated sodium chloride solution to the reacted solution, stir and wash, then extract with 300mL of methyl tert-butyl ether for 3 times, and extract the solution with 250g of After drying and dehydrating with sodium sulfate for 3 hours, filter the filtrate and concentrate it with a rotary evaporator until no liquid drips out from the condenser tube of the evaporator. The obtained crude product is purified by column chromatography to obtain 4-acrylamidobutyraldehyde dimethyl aldehyde.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com