Layered double hydroxide/graphene nano composite gas sensitive material and preparation method thereof, and application in detection of nitrogen dioxide

A layered bimetal and hydroxide technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as long response recovery time, weak response signal, sensor detection limit, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Preparation of Graphene Oxide

[0023] Graphene oxide was prepared by the traditional Hummers method. Place a 250ml reaction bottle in an ice-water bath, slowly pour 30ml of concentrated sulfuric acid, add 1g of graphite powder and 0.5g of sodium nitrate under constant stirring, and then slowly add 5g of potassium permanganate, and control the reaction temperature not to exceed 20°C. After stirring for 30 minutes, raise the temperature to 35°C, continue to stir for 30 minutes, then add 40ml of deionized water, raise the temperature to 98°C, continue heating for 20 minutes, the solution is brownish yellow, then add 5ml of hydrogen peroxide, filter the sample while it is hot, It was washed with hydrochloric acid and deionized water, and finally fully dried in a 60°C drying oven.

[0024] Step 2: Preparation of ZnTi-LDH / GO nanocomposite

[0025] Using urea as alkali source, ZnTi-LDH / GO with three-dimensional structure was prepared by hydrothermal method. Measure...

Embodiment 2

[0034]The difference between this embodiment and embodiment 1 is: the amount of graphene oxide in step 2 is increased to 4.92g.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is: the amount of graphene oxide in step (2) is reduced to 0.55g.

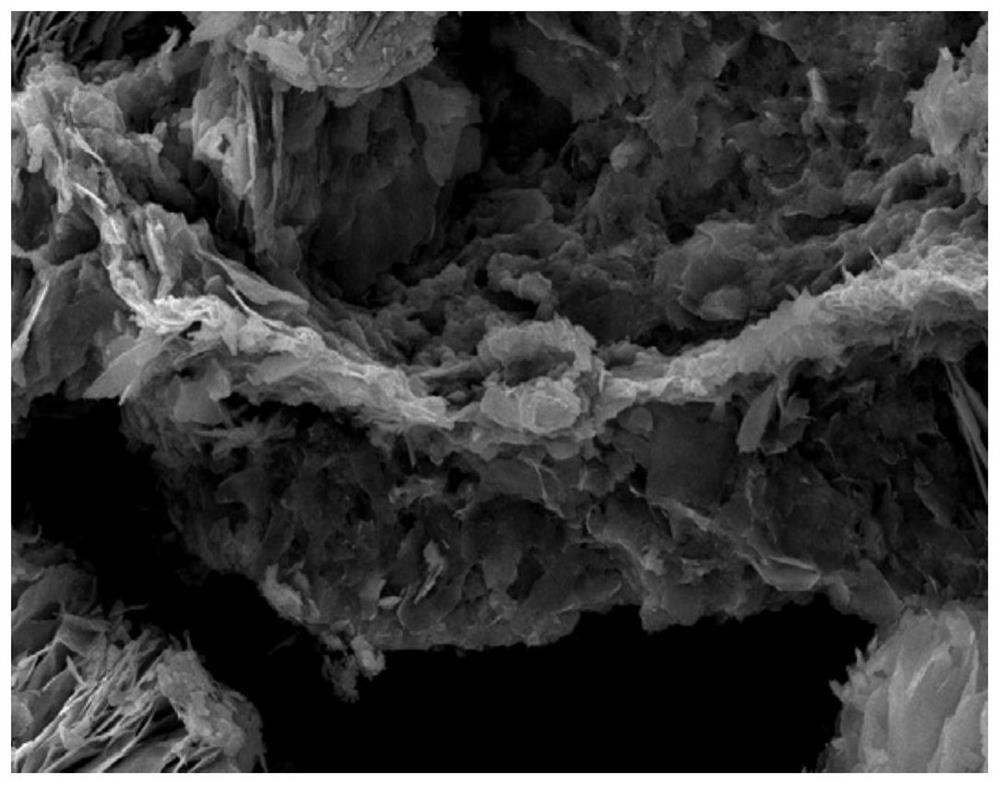

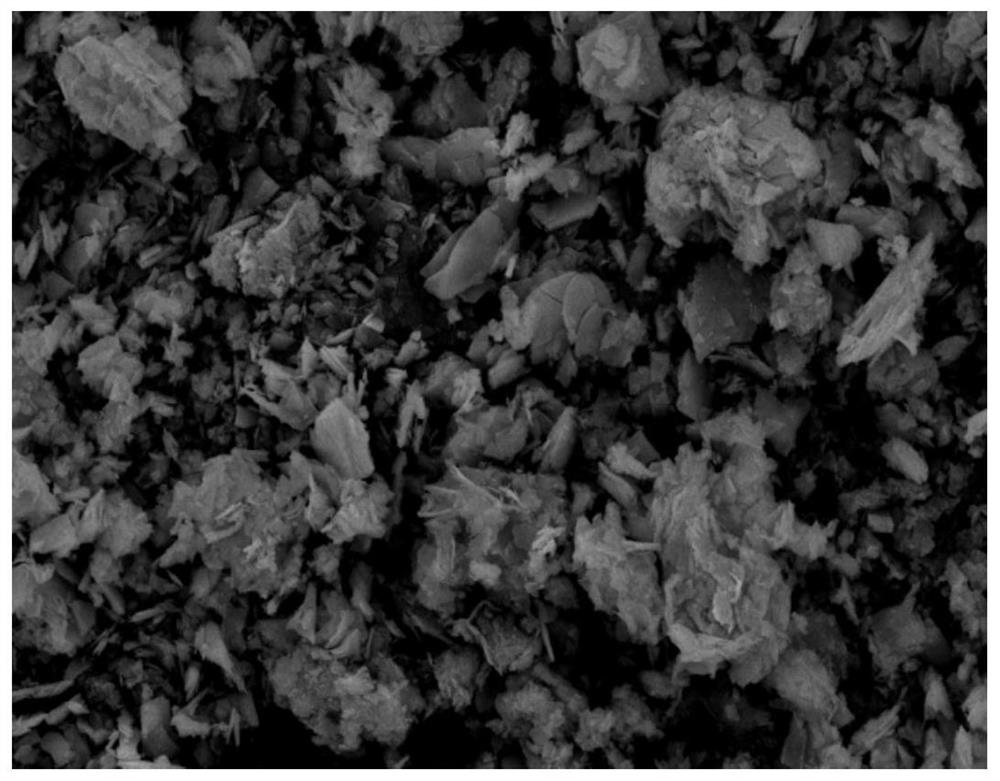

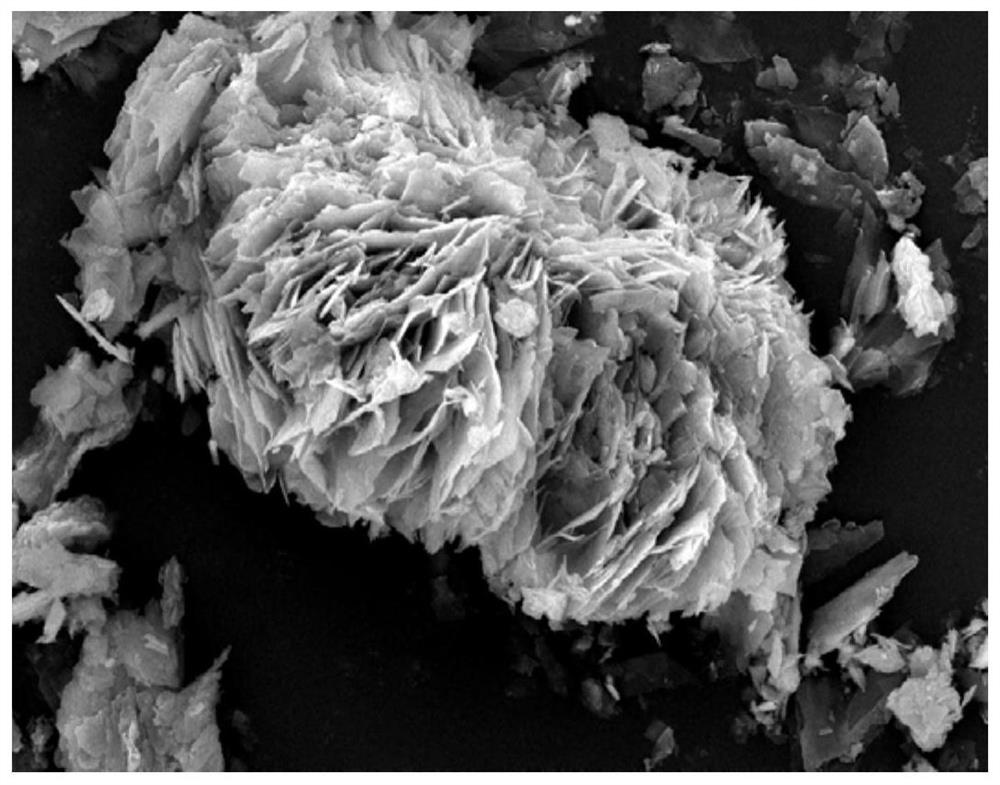

[0037] Such as figure 1 Shown, the ZnTi-LDH / GO nanocomposite material that embodiment 1 makes, its LDH grows on the graphene nanosheet with the form of nanosheet, distributes evenly and densely, and the specific surface area of the three-dimensional structure that forms is big; figure 2 Shown, the ZnTi-LDH / GO nanocomposite material that the graphene oxide amount that embodiment 2 makes increases, along with the increase of graphene oxide, the phenomenon that local lamellar accumulation, agglomeration into particle has occurred; image 3 As shown, the ZnTi-LDH / GO nanocomposite material with reduced graphene oxide content obtained in Example 3, with the increase and decrease of graphene oxide, the phenomenon of lamellar accumulation and disordered structure appeared. In summary, when the concentration of graphene oxide in the reaction solution is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com