Waterproof adhesive mortar for exterior wall tiles

A waterproof adhesive tile technology, applied in the field of mortar production, can solve problems such as unsatisfactory strength and paste stability, slow increase in actual strength, unsatisfactory impermeability, etc., to improve freeze-thaw resistance performance, simple and convenient construction , excellent bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

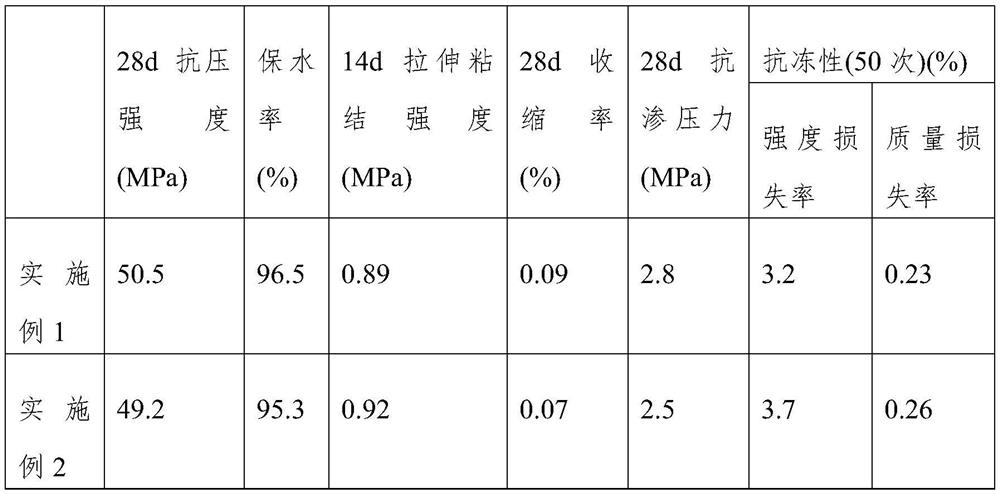

Embodiment 1

[0033] A waterproof bonding mortar for exterior wall tiles, comprising the following components: 480kg of cement, 550kg of quartz sand, 18kg of waterproofing agent, 3kg of cellulose, and 12kg of hydrophobic agent;

[0034] Described waterproofing agent is made up of following components: paraffin 10kg, sodium bicarbonate 3kg, soap powder 4kg, diatom extract 8kg, ethyl paraben 2kg;

[0035] The preparation method of the diatom extract is:

[0036] S1: after mixing diatom and quicklime in a mass ratio of 1:0.6, heating the material to 80°C, keeping the temperature for 10-15min, then washing with clean water and then squeezing and filtering to obtain filtrate A and filter residue A;

[0037] S2: place the filter residue A in a citric acid solution with a mass concentration of 70% and an amount that is 2.5 times the mass of the filter residue A, soak it for 30min at 0-5°C, and filter to obtain filtrate B and filter residue B;

[0038] S3: after mixing filter residue B and sodium ...

Embodiment 2

[0043] A waterproof bonding mortar for exterior wall tiles, comprising the following components: 430kg of cement, 500kg of quartz sand, 15kg of waterproofing agent, 1kg of cellulose, and 8kg of hydrophobic agent;

[0044] Described waterproofing agent is made up of following components: paraffin 8kg, sodium bicarbonate 2kg, soap powder 4kg, diatom extract 5kg, ethyl paraben 1kg;

[0045] The preparation method of the diatom extract is:

[0046] S1: after mixing diatom and quicklime in a mass ratio of 1:0.4, heating the material to 70 ° C, keeping the temperature for 10 min, then washing with clean water and then squeezing and filtering to obtain filtrate A and filter residue A;

[0047] S2: place the filter residue A in a citric acid solution with a mass concentration of 50% and an amount of 1.5 times the mass of the filter residue A, soak it for 20min at 0-5°C, and filter to obtain filtrate B and filter residue B;

[0048]S3: After mixing filter residue B and sodium chloride...

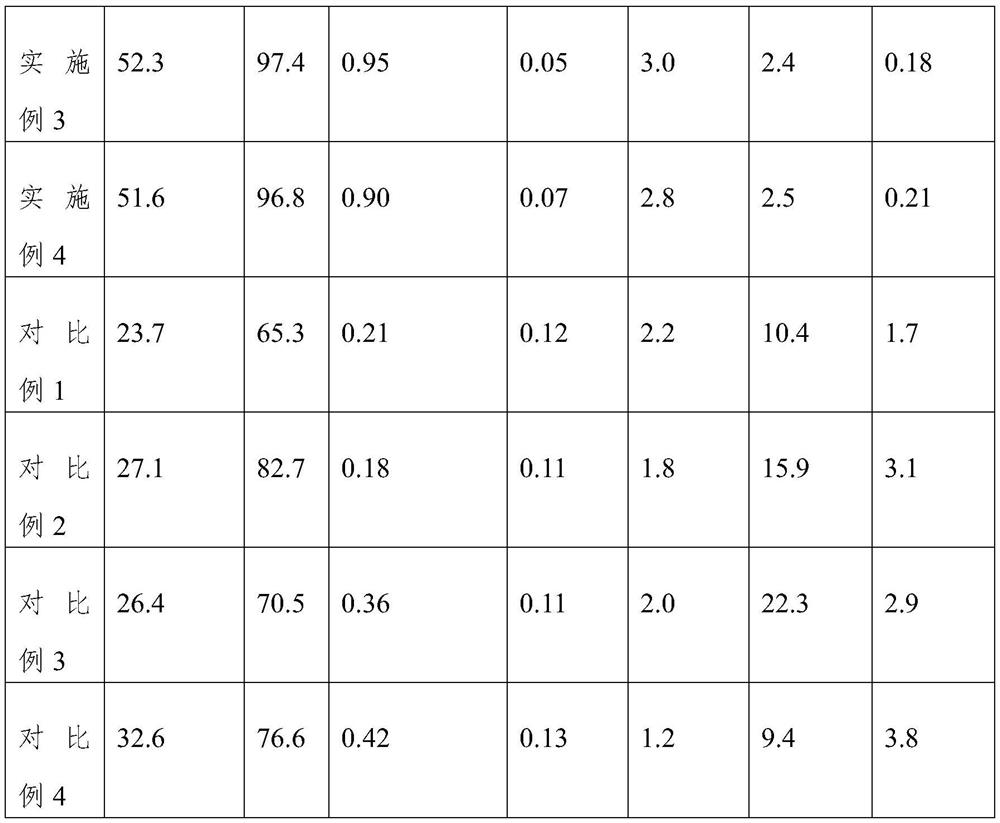

Embodiment 3

[0053] A waterproof bonding mortar for exterior wall tiles, comprising the following components: 430kg of cement, 550kg of quartz sand, 18kg of waterproofing agent, 3kg of cellulose, and 8kg of hydrophobic agent;

[0054] The waterproofing agent is composed of the following components: 9kg of paraffin, 2.5kg of sodium bicarbonate, 5kg of soap powder, 6.5kg of diatom extract, and 1.5kg of ethyl p-hydroxybenzoate;

[0055] The preparation method of described diatom extract is:

[0056] S1: After mixing diatoms and quicklime at a mass ratio of 1:0.5, heat the material to 75°C, keep it warm for 12 minutes, then wash it with clean water, squeeze and filter to obtain filtrate A and filter residue A;

[0057] S2: Put the filter residue A in a citric acid solution with a mass concentration of 60% and an amount twice the mass of the filter residue A, soak at 0-5°C for 25 minutes, and then filter to obtain filtrate B and filter residue B;

[0058] S3: After mixing the filter residue B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com