Fluorenyl terpolymer/ferric oxide nanoparticle composite material, preparation method and application of same in electric storage device

A fluorene-based terpolymer, ferric oxide technology, applied in the direction of electric solid device, semiconductor/solid device manufacturing, electrical components, etc., can solve the problem of poor performance repeatability and stability of the active layer, easy aggregation, inorganic nanometer The material is not easy to disperse and other problems, to achieve the effect of enhanced transmission and capture, easy realization of the preparation process, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] The technical solution of the present invention is not limited to the following specific embodiments, but also includes any combination of the specific embodiments.

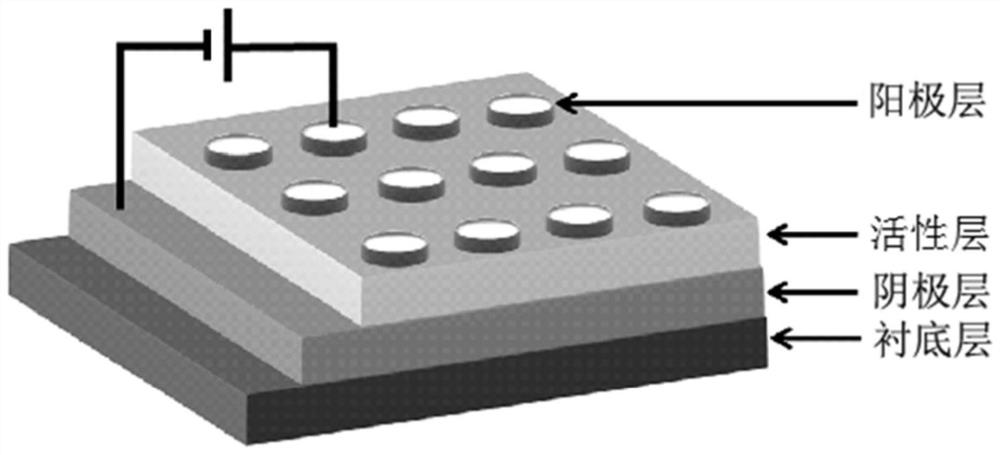

[0040] The invention utilizes the fluorene-based terpolymer and ferric oxide nanoparticles to form a composite material, wherein the ferric oxide nanoparticles are evenly distributed, which can enhance the capture and transmission of carriers in the composite material, and effectively improve the activity of the storage device. layer stability.

[0041] The fluorene-based terpolymer / ferric oxide nanoparticle composite material in the present invention is physically doped with the fluorene-based terpolymer and ferric oxide nanoparticles.

[0042] The fluorene-based terpolymer is a carbazole-fluorene-benzimidazole terpolymer, which is obtained by polymerizing a halogenated carbazole monomer, a halogenated benzimidazole monomer and a fluorene monomer.

[0043] The preparation method of described fluorenyl te...

Embodiment 1

[0146] in N 2 Under the atmosphere, put 1.49g of 2,3-naphthalene dicarboxylic anhydride, 0.27g of 3,6-dibromo-1,2-phenylenediamine, and 10mL of glacial acetic acid into the reaction vessel, stir and raise the temperature to 108°C, reflux the solvent, and carry out Constant temperature reaction for 6 hours.

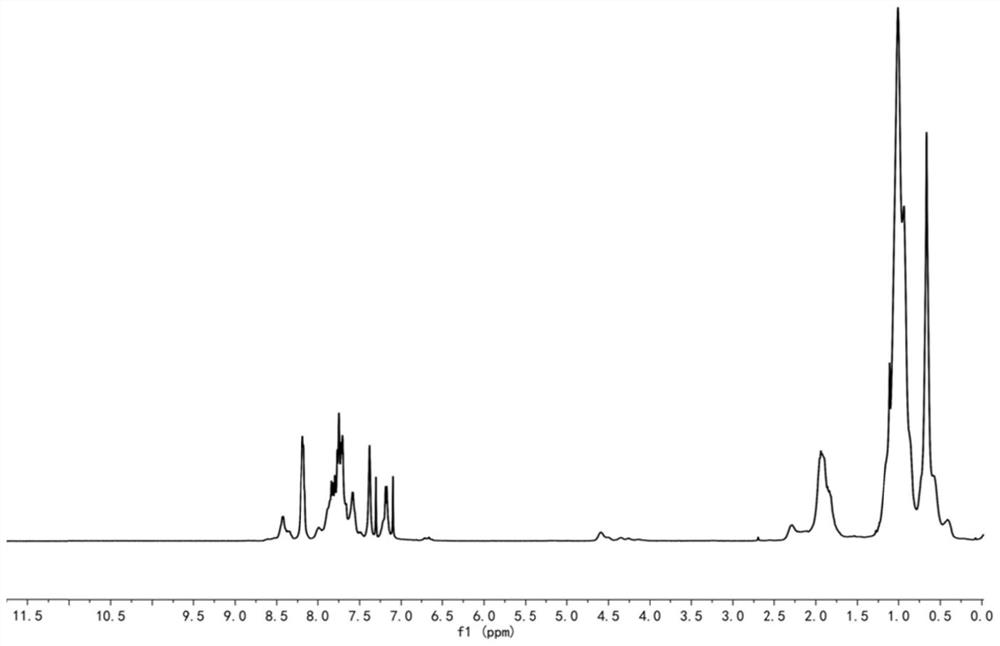

[0147] After the reaction, the reaction solution was cooled to room temperature, and the crude product was gradually precipitated, filtered, and washed with deionized water until neutral. The obtained crude product was put into a vacuum drying oven for drying, the temperature of vacuum drying was 85°C, the time of vacuum drying was 12 hours, and the pressure of vacuum drying was -30kPa. The crude product after drying is separated and purified by column chromatography. The stationary phase of the chromatography column is silica gel powder, and the liquid phase is a mixed solution of dichloromethane and petroleum ether. The volume ratio of the two is 3:1 to obtain benzimida...

Embodiment 2

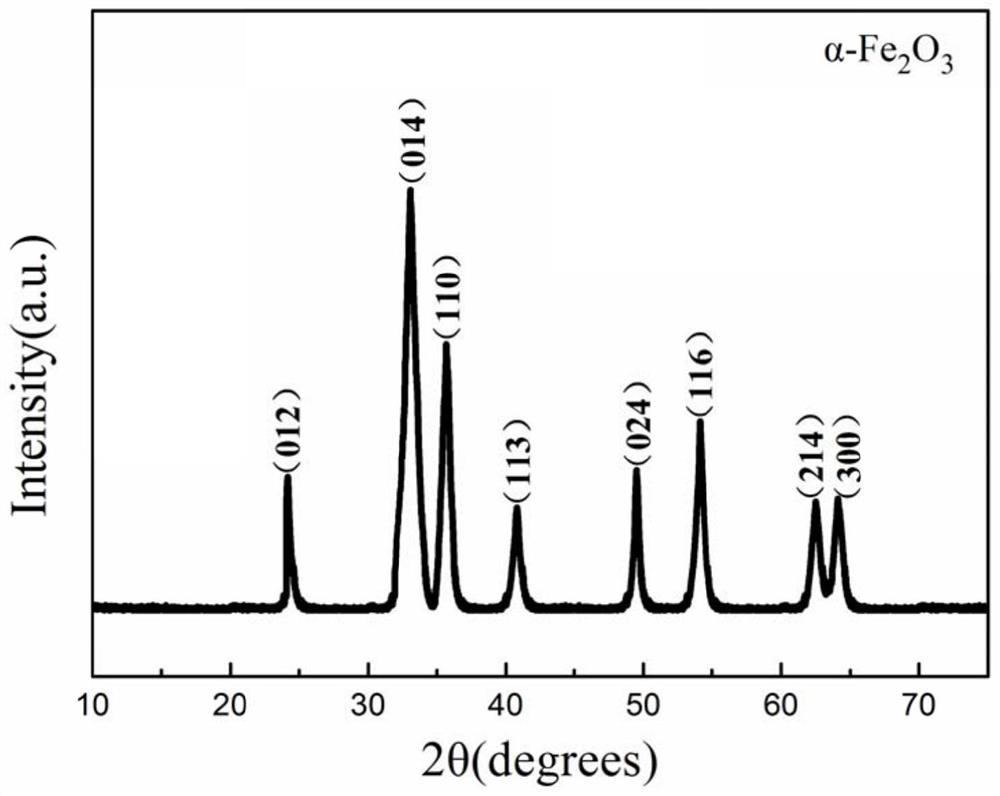

[0152] Accurately weigh 1.616g ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 (2), 2.0g urea, 20mL distilled water, 9mL ethanol and 1mL ethanolamine were added to a 100mL beaker with magnetic stirring, and after completely dissolving, 0.5g sodium nitrate and 0.5g sodium dodecyl sulfate (SDS) were added, and finally 5mL of N,N-Dimethylformamide (DMF). Stirring was stopped, and the mixed solution was ultrasonically treated for 30 min, then transferred to a washed and dried 100 mL autoclave, sealed and reacted at a constant temperature of 120 °C for 20 h. After the reaction was completed, it was cooled to room temperature, and the product was washed several times by centrifugation with deionized water and absolute ethanol, and the final product was vacuum-dried at 50°C for 6 hours to obtain reddish-brown powdery ferric oxide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com