Preparation method of iso-tridecanol

A technology of isotridecanol and isomerization, which is applied in the field of preparation of isotridecanol, can solve the problems of high branching degree of dimer, easy carbon deposition of molecular sieve catalyst, serious isomerization of products, etc. The effect of solving the shortage of sources and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

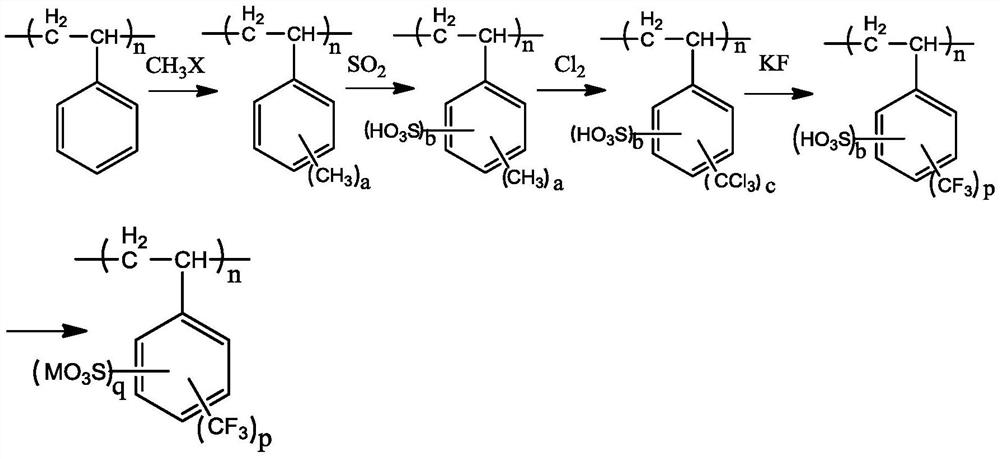

[0037] (1) Dimerization: preparation of resin catalyst: add 100g macroporous polystyrene resin (Dandong Pearl) and 200ml dichloromethane solvent into the reactor, add 2g aluminum trichloride as catalyst, add 20g methyl iodide, and the reaction temperature is 50°C , the reaction time is 1h, filter after the reaction is over, dry at 120°C for 24h to obtain 102g methyl polystyrene resin, transfer the methyl polystyrene resin to the reaction kettle, feed 102g sulfur dioxide to react, the reaction temperature is 40°C, the reaction time 1h, discharge the unreacted sulfur dioxide, replace with nitrogen three times, generate 120g of methyl polystyrene sulfonic acid resin, add 240g of chlorine to the reaction kettle to continue the reaction, the reaction temperature is 60°C, and the reaction time is 3h, discharge the unreacted chlorine, nitrogen Replace three times to generate 130g of trichloromethyl polystyrene sulfonic acid resin, add 260g of potassium fluoride aqueous solution with a...

Embodiment 2

[0051] (1) Dimerization: Add 100g of macroporous polystyrene resin (Dandong Pearl) and 200ml of dichloromethane solvent into the reactor, add 5g of titanium tetrachloride as a catalyst, feed 30g of methyl bromide, the reaction temperature is 150°C, and the reaction time is 5h , filtered after the reaction, dried at 110°C for 48h to obtain 105g of methyl polystyrene resin, transferred the methyl polystyrene resin to the reaction kettle, added 210g of sulfur dioxide to react, the reaction temperature was 150°C, the reaction time was 4h, and the unreacted 120g of methyl polystyrene sulfonic acid resin is generated, and 480g of chlorine gas is added to the reaction kettle to continue the reaction. The reaction temperature is 120°C, and the reaction time is 6h. The unreacted chlorine gas is discharged, and nitrogen gas is replaced three times to generate 125g Trichloromethyl polystyrene sulfonic acid resin, add 500g of potassium fluoride aqueous solution with a mass concentration of...

Embodiment 3

[0067] (1) Dimerization: Add 100g of macroporous polystyrene resin (Dandong Pearl) and 200ml of dichloromethane solvent into the reactor, add 7g of aluminum trichloride as a catalyst, feed 25g of methyl chloride gas, and react at a temperature of 80°C. Time 2h, filter after the reaction is over, dry at 120°C for 24h to obtain 105 methyl polystyrene resin, transfer the methyl polystyrene resin to the reactor, feed 158g of sulfur dioxide to react, the reaction temperature is 70°C, the reaction time is 2h, Exhaust excess sulfur dioxide, replace with nitrogen three times to obtain 110g of methyl polystyrene sulfonic acid resin, add 330g of chlorine to the reaction kettle to continue the reaction, the reaction temperature is 90°C, the reaction time is 4h, discharge unreacted chlorine, and replace with nitrogen three times , to obtain 115g of trichloromethyl polystyrene sulfonic acid resin, add 345g of potassium fluoride aqueous solution with a mass concentration of 10% in the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com