Methanol fuel automobile exhaust purification catalyst and preparation method thereof

A technology for purifying catalysts and automobile exhaust gas, which is applied in the directions of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of high maximum conversion efficiency, low precious metal content, low light-off temperature, etc. The effect of low and high specific surface area and low light-off temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

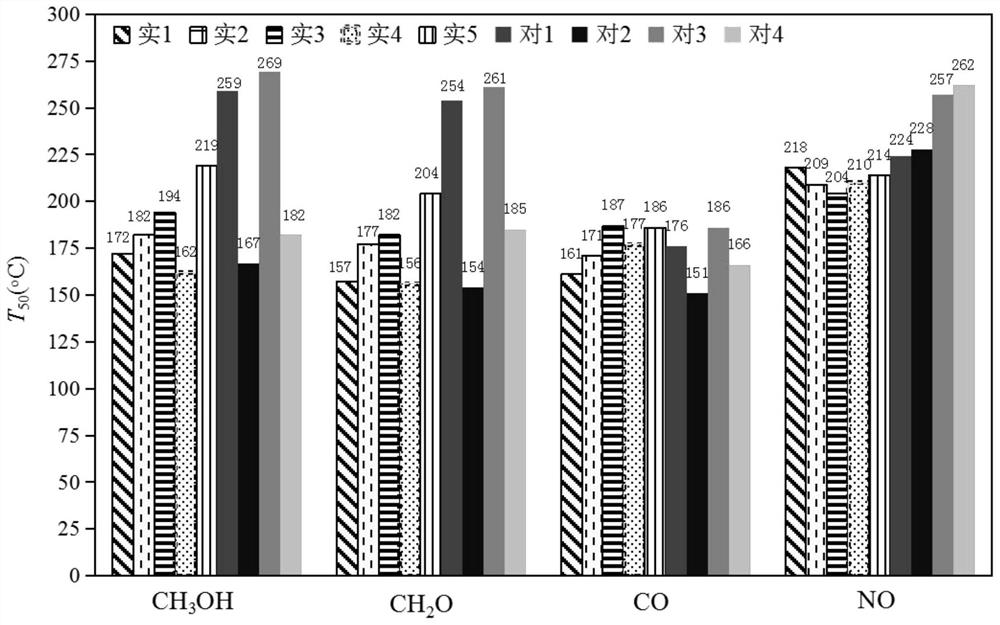

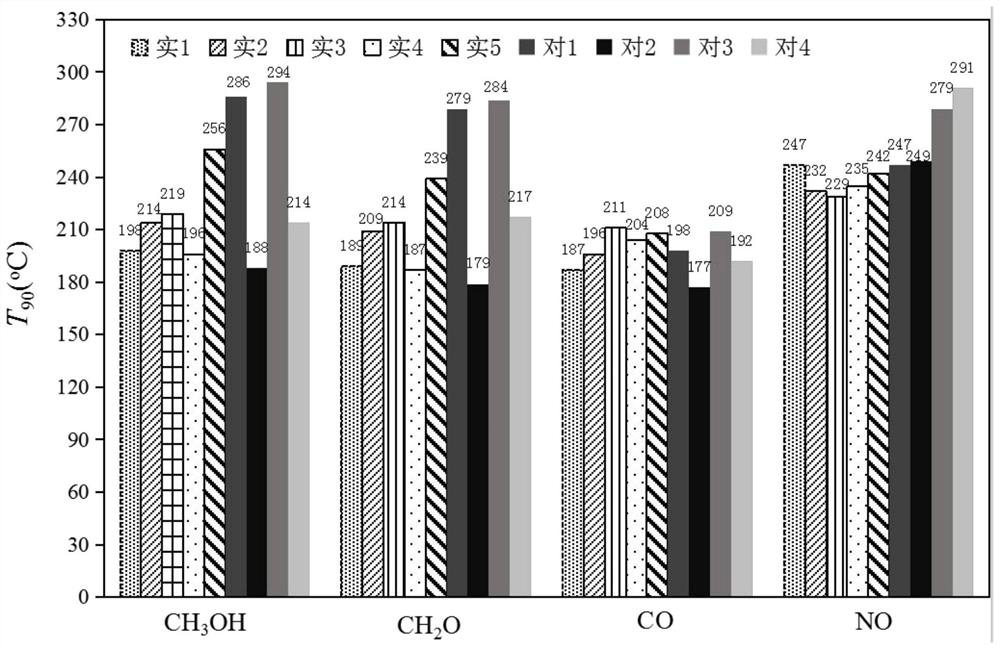

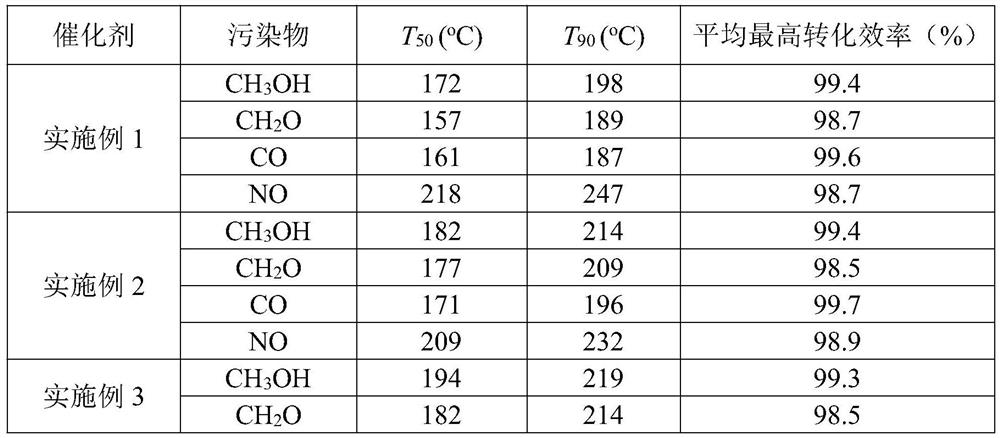

Examples

Embodiment 1

[0042] Dissolve zirconyl nitrate in water to prepare zirconyl nitrate solution, add zirconyl nitrate solution and aluminum nitrate to deionized water, stir and mix to form a salt solution, wherein the mass ratio of zirconyl nitrate and aluminum nitrate to deionized water is 1 :9, add ammonia water to adjust the pH of the salt solution to 8.8-9.5, and prepare the precipitate by co-precipitation method. After treatment, the material obtained by the co-precipitation method is roasted in an air atmosphere of 550 ° C for 3 h, and then continue to be heated at 900 ° C. Roasted in air atmosphere for 3h to get ZrO 2 -Al 2 o 3 , where ZrO 2 The mole percentage is 50%, ZrO 2 -Al 2 o 3 The particle size is 3-12μm, and the specific surface area is 93m 2 / g, pore volume 0.20ml / g; mix the palladium nitrate solution and the platinum nitrate solution evenly, and then load the ZrO prepared above by the equal volume impregnation method 2 -Al 2 o 3 , dried at 100°C for 5h, and then fire...

Embodiment 2

[0047] Dissolve zirconyl nitrate in water to prepare zirconyl nitrate solution, add zirconyl nitrate solution and aluminum nitrate to deionized water, stir and mix to form a salt solution, wherein the mass ratio of zirconyl nitrate and aluminum nitrate to deionized water is 1 :9, add ammonia water to adjust the pH of the salt solution to 8.8-9.5, and prepare the precipitate by co-precipitation method. After treatment, the material obtained by the co-precipitation method is roasted in an air atmosphere of 550 ° C for 3 h, and then continue to be heated at 950 ° C. Roasted in air atmosphere for 3h to get ZrO 2 -Al 2 o 3 , where ZrO 2 The mole percentage is 30%, ZrO 2 -Al 2 o 3 The particle size is 3-12μm, and the specific surface area is 98m 2 / g, pore volume 0.21ml / g; mix the palladium chloride solution and the platinum chloride solution evenly, and then load the ZrO prepared above by the equal volume impregnation method 2 -Al 2 o 3 , dried at 100°C for 5h, and then fi...

Embodiment 3

[0052] Dissolve zirconyl carbonate into nitric acid solution to prepare zirconyl carbonate solution, add zirconyl carbonate solution and aluminum nitrate to deionized water, stir and mix to form a salt solution, wherein the mass ratio of zirconyl carbonate and aluminum nitrate to deionized water is 1:9, add ammonia water to adjust the pH of the salt solution to 8.8-9.5, and prepare the precipitate by the co-precipitation method. After treatment, the material obtained by the co-precipitation method is roasted in an air atmosphere at 550 ° C for 3 hours, and then continue to be in the Calcined in air atmosphere at 850°C for 3h to obtain ZrO 2 -Al2 o 3 , where ZrO 2 The mole percentage is 70%, ZrO 2 -Al 2 o 3 The particle size is 3-12μm, and the specific surface area is 87m 2 / g, pore volume 0.19ml / g; tetraammine palladium nitrate solution and tetraamine platinum nitrate solution are mixed evenly, and then loaded onto the ZrO prepared above by equal volume impregnation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com