Preparation method of natural anti-wrinkle cosmetic material

An anti-wrinkle cosmetic, natural technology, applied in the preparation method of peptides, cosmetic preparations, cosmetics, etc., can solve environmental pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

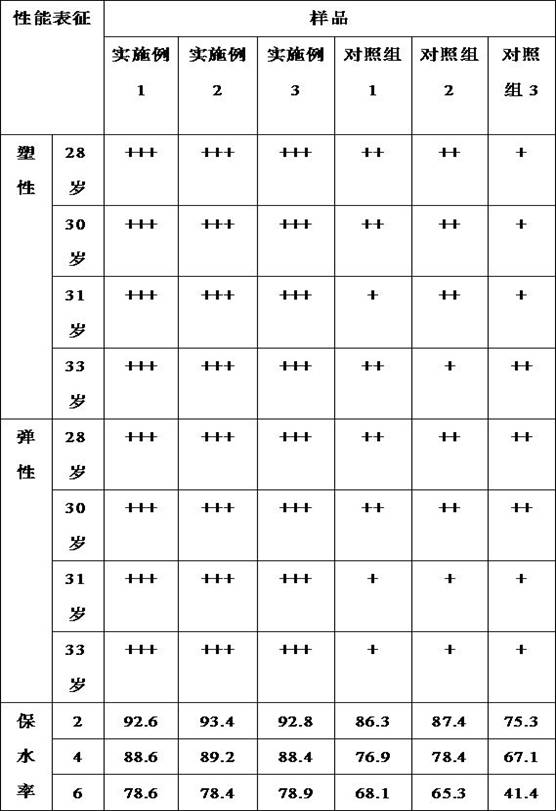

Examples

Embodiment 1

[0064] Take fresh silk and mix it with a mass fraction of 1% sodium carbonate solution at a mass ratio of 1:5, place it in a water bath at 120°C for 1 hour, let it cool down to room temperature, filter and collect the filter cake, and vacuum freeze-dry To obtain dry granules, weigh 85 parts by weight of 45% ethanol solution, 10 parts of calcium chloride and 6 parts of dry granules in Erlenmeyer flasks, stir and mix them and place them at 75°C to insulate and dissolve. The solution was collected and dialyzed, the dialysate was collected and placed in a rotary evaporation process at 35°C, and the rotary evaporation was reduced to 1 / 5 of the original volume to obtain silk fibroin particles; by weight, 45 parts of deionized water, 10 1 part of silk fibroin granules and 1 part of phospholipid were placed in an Erlenmeyer flask, stirred and mixed and placed in a homogenizing device, homogenized at 25 MPa for 25 minutes, and the phospholipid complex solution was collected; then weighe...

Embodiment 2

[0067] Take fresh silk and mix it with a mass fraction of 1% sodium carbonate solution according to the mass ratio of 1:5, and place it in a water bath at 125°C for 1 hour, let it cool down to room temperature, filter and collect the filter cake, and vacuum freeze-dry To obtain dry granules, weigh 87 parts by weight of 45% ethanol solution, 12 parts of calcium chloride and 7 parts of dry granules respectively in Erlenmeyer flasks, stir and mix them and place them at 77°C to insulate and dissolve. The solution was collected and dialyzed, the dialysate was collected and placed in a rotary evaporation process at 40°C, and the rotary evaporation was reduced to 1 / 5 of the original volume to obtain silk fibroin particles; in parts by weight, 47 parts of deionized water, 12 1 part of silk fibroin granules and 1 part of phospholipid were placed in an Erlenmeyer flask, stirred and mixed and placed in a homogenizing device, homogenized at 27 MPa for 27 minutes, and the phospholipid compl...

Embodiment 3

[0070] Take fresh silk and mix it with a mass fraction of 1% sodium carbonate solution at a mass ratio of 1:5, place it in a water bath at 130°C for 2 hours, let it cool down to room temperature, filter and collect the filter cake, and vacuum freeze-dry To obtain dry granules, weigh 90 parts by weight of 45% ethanol solution, 15 parts of calcium chloride, and 8 parts of dry granules in Erlenmeyer flasks, stir and mix them, and place them at 80°C to insulate and dissolve. The solution was collected and dialyzed, the dialysate was collected and placed in a rotary evaporation process at 45°C, and the rotary evaporation was reduced to 1 / 5 of the original volume to obtain silk fibroin particles; by weight, 50 parts of deionized water, 15 1 part of silk fibroin granules and 2 parts of phospholipids were placed in an Erlenmeyer flask, stirred and mixed and placed in a homogenization device, homogenized at 30 MPa for 30 minutes, and the phospholipid complex solution was collected; then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com