Ion-conductive nano-cellulose-based capacitive humidity sensor and preparation method thereof

A nano-cellulose and humidity sensor technology, applied in the direction of material capacitance, instruments, scientific instruments, etc., can solve the problems that the dielectric layer cannot be directly applied and the surface roughness is high, and achieve miniaturization, good biological safety, and wide-ranging sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

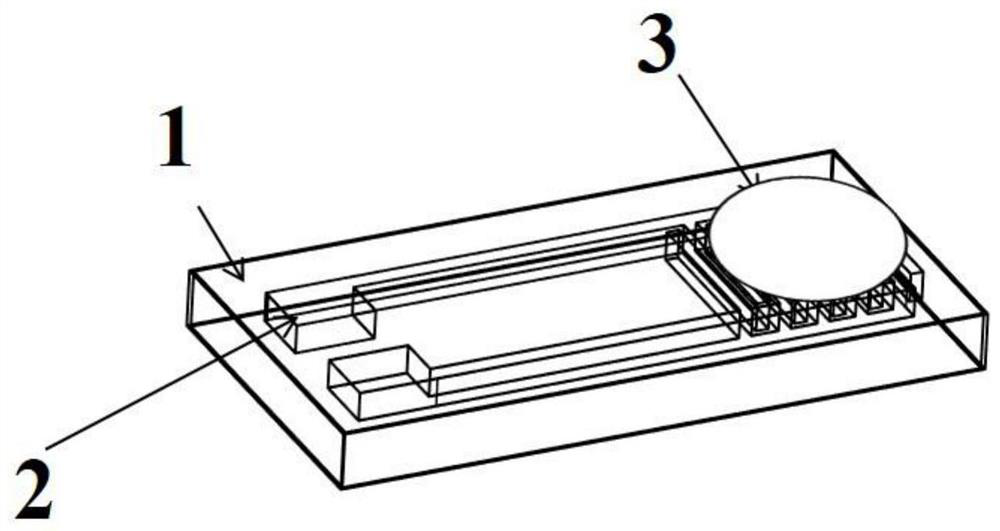

[0038] In this embodiment, the substrate 1 is a glass sheet, the electrode 2 is produced by vacuum thermal evaporation physical vapor deposition method, the nanocellulose solution is prepared by TEMPO oxidation method, and the nanocellulose-based thin film layer is prepared by drip coating with a pipette gun.

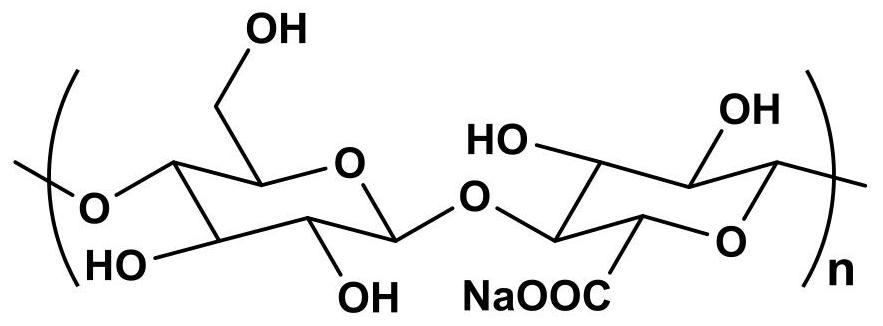

[0039]Step 1, adopt wood pulp to prepare nanocellulose solution, specifically as follows:

[0040] In step 1-1, 100 mg of TEMPO (2,2,6,6-tetramethylpiperidine oxide) reagent was ultrasonically treated for 20 minutes, and then uniformly dissolved in 95 mL of deionized water to form a TEMPO aqueous solution;

[0041] Step 1-2, uniformly dissolve 659mg of sodium bromide solution in 65mL of deionized water, and uniformly mix with TEMPO aqueous solution, then mechanically stir 6.5g of softwood pulp in 80mL of deionized water to form a pulp suspension, then, add sodium bromide Add 38mL of the mixed aqueous solution with TEMPO and 12wt% sodium hypochlorite solution to the cork...

Embodiment 2

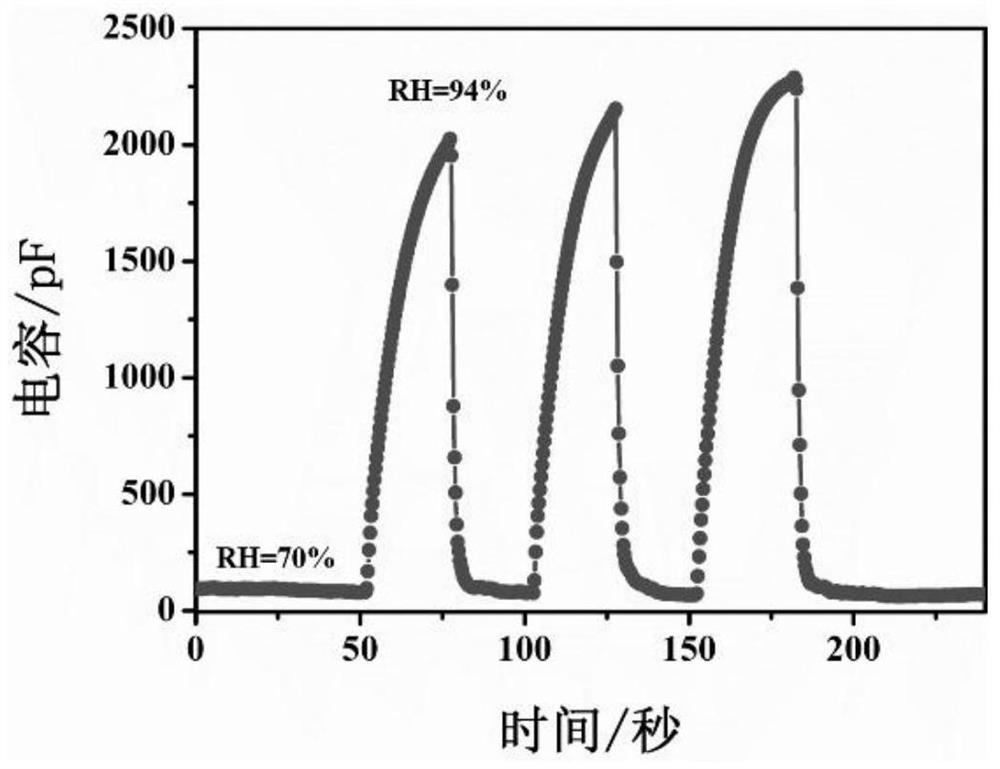

[0054] The material, preparation method and preparation process used in this embodiment are the same as those in the first embodiment, and the purpose is to detect the monitoring of the small humidity difference by the sensor, and the capacitance change is used as the output signal.

[0055] Figure 4 The ion-conductive nanocellulose-based capacitive humidity sensor prepared by this technology is based on the response test chart of capacitance change to humidity of 60% and 61%.

[0056] The test process is as follows: fix the ion-conductive nanocellulose-based capacitive humidity sensor in an environment with a humidity of 60%, connect the source electrode and the drain electrode through a wire, and connect the sensor to a TH2827C LCR meter through a wire, and adjust the test After the device works, test the capacitive output signal of the sensor, and use the capacitive output signal as an electrical signal, and record the output characteristics of the sensor after the capacit...

Embodiment 3

[0060] The material, preparation method and preparation process used in this embodiment are the same as those in the first embodiment, and the purpose is to test the schematic diagram of the response of capacitance with frequency under different humidity conditions.

[0061] Figure 5 The capacitive response of the ion-conducting nanocellulose-based capacitive humidity sensor prepared by this technology to different frequencies under different humidity is shown in this example.

[0062] The test process is as follows: fix the ion-conductive nanocellulose-based capacitive humidity sensors in closed chambers with humidity of 7%, 24%, 47%, 61%, 75%, 83%, and 94%, respectively, and wire the sensors to Connect with TH2827C type LCR meter testing instrument. After adjusting the test device to work, cover the lid of the cavity, test the capacitance signal of the sensor, and use the capacitance signal as an electrical signal. After the signal is stable, record the change of the capa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com