Preparation method of bacterial cellulose LDH composite adsorption material

A technology of composite adsorption material and bacterial cellulose, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of single adsorption method of bacterial cellulose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

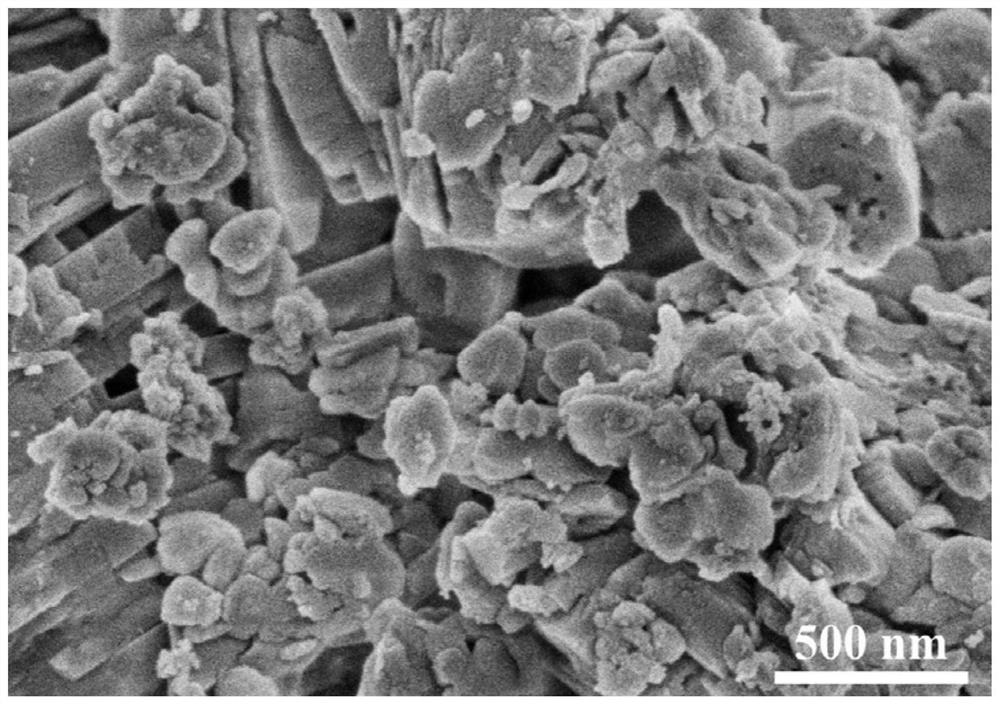

Image

Examples

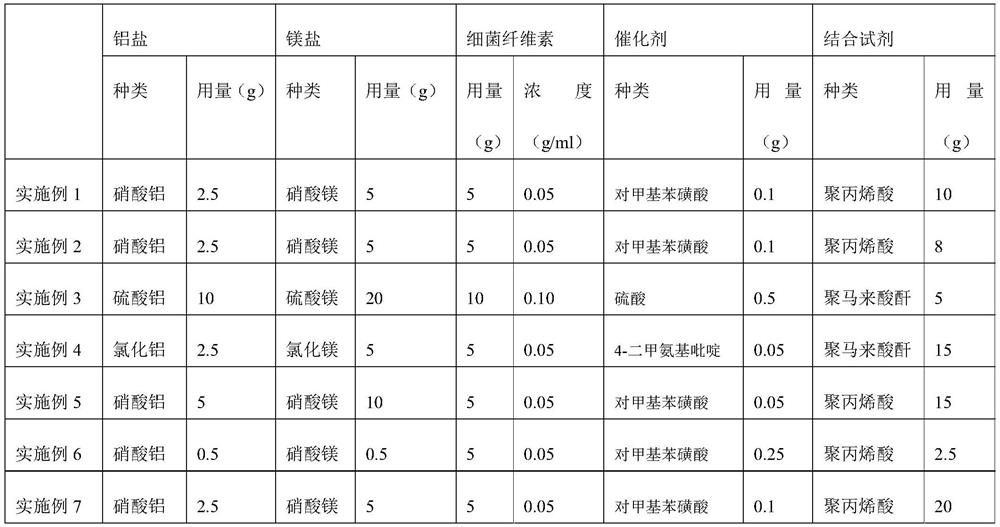

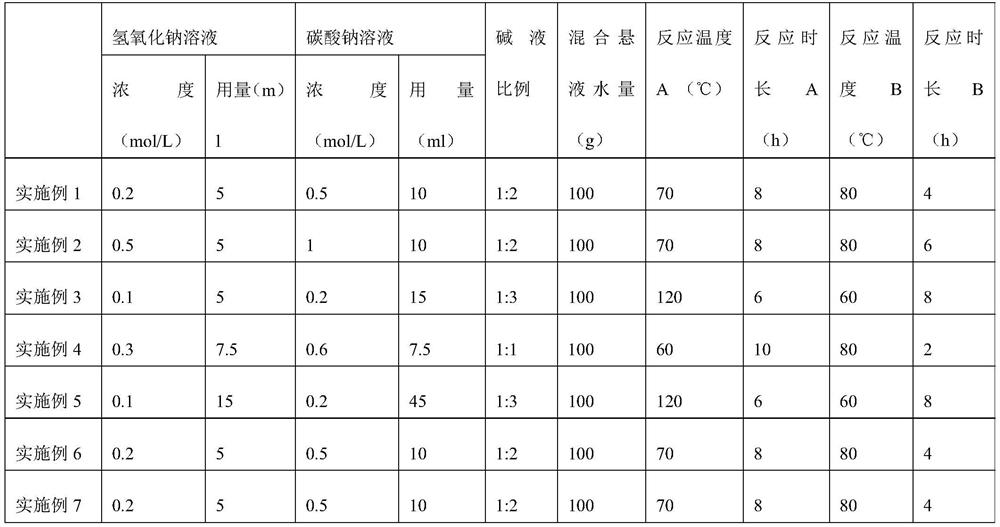

Embodiment 1

[0034] Example 1: Add 5 g of bacterial cellulose powder (Hainan Yide Food Co., Ltd.) into 100 ml of deionized water, stir to disperse it, and obtain a bacterial cellulose dispersion. Add 2.5 g of aluminum nitrate and 5 g of magnesium nitrate to the bacterial cellulose dispersion and stir to dissolve the aluminum nitrate and magnesium nitrate to obtain a co-precipitation system. Mix 5ml of prepared 0.2mol / L sodium hydroxide solution with 10ml of 0.5mol / L sodium carbonate solution to obtain 15ml coprecipitant. Add the co-precipitation agent dropwise to the constantly stirring co-precipitation system, and then heat at 70°C for 8 hours. The obtained solid product (precipitation, that is, the adsorption matrix material) is filtered and washed to neutrality, and 100g of deionized water is added to obtain a mixed Suspension. After heating the mixed suspension to 80°C, add 0.1g of p-toluenesulfonic acid and 10g of polyacrylic acid (molecular weight: 2000-5000) and stir for 4 hours. A...

experiment example

[0048] (1) Preparation of Cu(II) standard curve

[0049] Weigh 1.0g of anhydrous copper sulfate standard sample with a balance, put the weighed solid into a 200ml beaker, add 100ml of ethanol solution dropwise, stir, and heat the beaker to 60°C to ensure that the solid sample is completely dissolved. Return to room temperature, transfer it to a 1000ml volumetric flask, and dilute to volume. Take the above prepared 1.0ml of Cu(II) standard solution with a concentration of 10 μg / ml, transfer it to a 50ml volumetric flask, add 4.0ml of ammonia solution (ammonia:water=1:1), 2.0ml of citric acid (0.5 g / ml); 10.0ml bicyclohexanone oxalthalin two brown solution (0.1%), constant volume. Take 1.2ml, 1.4ml, 1.6ml, 2.0ml standard solutions and prepare them according to the above method. Choose a 1ml cuvette at 610nm and use a blank sample as a reference solution. After preheating for 10 minutes, use a UV-spectrophotometer to measure the absorbance. The equation of Cu(II) standard work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com